Introducing 4D polymer printing

Scientists in the US have added a new dimension to 3D printing with a strategy that controls the chemical composition of printed features, as well as their three-dimensional position.

With 3D printing systems becoming more mainstream, platforms that overcome their current limitations are increasingly relevant. Ideally, they should print different polymers close together, independently control their position and be compatible with delicate organic and biologically active materials.

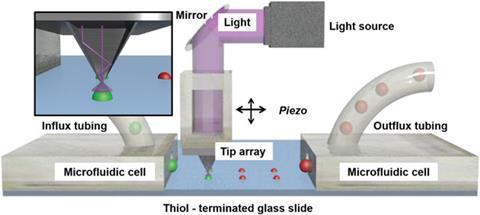

A team at the University of Miami led by Adam Braunschweig has designed such a system involving entirely solution-based patterning reactions for the first time. It combines 1cm2 parallel tip arrays, microfluidics and photochemical polymerisations to grow brush polymers on a glass surface. The process itself takes just a few steps and achieves sub-micrometre resolution without using high-energy beams.

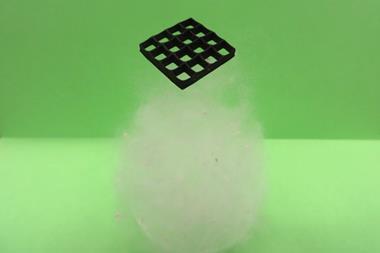

Components of the polymerisation reaction – monomer, photoinitiator and solvent – flow into a microfluidic cell fitted with a tip array. Each array has around 15,000 polydimethylsiloxane pyramids spaced at 80µm intervals, which localise light shone onto them. This light initiates the reaction, making patterns of brush polymers on the surface below. To create an adjacent pattern of different chemical composition, the tips are simply moved, a new monomer solution introduced to the rinsed cell and the process repeated. Tip position controls the location of a printed feature, light exposure duration the degree of polymerisation and therefore height, while monomer identity determines the chemical composition.

Braunschweig sees huge potential for their 4D printing process, with possible applications including gene chips, protein arrays and stimuli responsive surfaces. The ultimate goal is recreating the architectural complexity and chemical properties of biological interfaces like the cell surface over large areas: ‘We’re still a long way off, but that is the motivation for our work.’

Ryan Chiechi, who heads a nanofabrication research group at the University of Groningen in the Netherlands, reinforces the significance of this work: ‘It allows local control of the interactions of adjacent polymeric features with, for example, cells whose properties can be drastically affected by both the surface chemistry and topology of a substrate in ways that we are only beginning to understand.’

References

X Liu et al, Polym. Chem., 2016, DOI: 10.1039/c6py00283h

No comments yet