Sustainable Extricko is using superheated steam and pressure to recycle intractable materials used in sailing

Joe Penhaul Smith and his brother Sam Penhaul are passionate about sailing. ‘We both grew up very close to the local sailing club,’ says Penhaul Smith, who continues to sail in his spare time. ‘Sam’s the professional sailor and has worked [building boats] for a lot of the very high-performance maritime teams.’

As co-founders of Sustainable Extricko, the brothers are now looking to make the sport that they love less wasteful, by recycling the composite textile materials that are extensively used in sailing.

‘Sam came back from Auckland [New Zealand] at the end of the 2021 America’s Cup [sailing competition] feeling quite frustrated,’ says Penhaul Smith. He explains that the team had spent a lot of money on high-quality materials only to use them once or twice, and never touch them again. ‘There’s all this time, effort and energy into building these wonderful pieces of chemistry, and then then it just ends up in a hole in the ground.’

Carbon and glass fibres significantly reduce the overall weight of materials without compromising on strength, making them a popular choice in technical industries where even the smallest differences can impact performance. Adding resins reinforces the material by binding the fibres together.

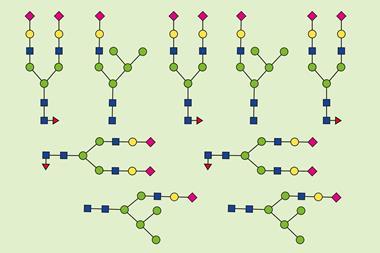

When these materials have reached the end of their use, the interwoven components can be difficult to separate, meaning that recycling rates of composite materials is less than 1%. Penhaul Smith explains that current recycling strategies include either pyrolysis – heating the materials in an inert environment to break them down – or solvolysis – dissolving the materials in hot solvents. These unsustainable and energy intensive methods can damage the fibres, cause loss of resin material and generate large amounts of solvent waste.

Sustainable Extricko uses an alternative method known as pressolysis – which uses superheated steam and pressure – to separate components. ‘Water is very effective at reacting with the relatively weak links that bind the fibres and resin together,’ explains Penhaul Smith. Varying the temperature and pressure can increase the overall efficiency and reduce the amount of energy needed to run the system.

After treatment, non-degradable materials, such as the carbon or glass fibres, are ready to use, assuming correct processing. ‘[Separating] the resins is the tricky bit, as you’ve now got an aqueous solution of interesting organic chemistry,’ says Penhaul Smith, who explains that further separation makes use of differing physical properties of the monomers, such as boiling point, density and responses to different pH. This uses a combination of existing technologies and newer methods developed by the team.

B&M Longworth originally developed pressolysis in 2004 and is currently supplying Sustainable Extricko with equipment to carry out test-scale composite material recycling. ‘What we’re fundamentally doing is changing the underpinning architecture [of the equipment], so you don’t necessarily have to rely on a steam boiler, particularly not industrial steam boilers that use gas [to generate heat],’ says Penhaul Smith. The adapted technology also operates without harmful organic solvents.

The brothers have currently tested their method using standalone batch systems, ranging from 14 up to 600 litres in size, and are able to process about 2 tonnes of composite materials per year. ‘It’s a drop in the ocean, but it’s two tonnes more than other organisations,’ says Penhaul Smith. While initially targeting the sailing industry, other markets that use composite materials – including aerospace, renewable energy and fashion – are ripe for this technology to take hold.

Current efforts are focusing on redesigning the system to work within a modular container unit. By turning waste into reusable materials at the source, the brothers believe that this approach will reduce transport costs, lower emissions and simplify the recycling process. Penhaul Smith explains that the company is securing funding to start building prototypes of these container systems, ‘hoping to operate with customers in the next couple of years’.

Sustainable Extricko aims to continue ‘recycling the historically unrecyclable’. ‘There are about 100,000 tonnes of composites waste [in the UK] … and as the EU continues to heavily regulate composite use, there’s quite a nice expansion route into Europe,’ says Penhaul Smith.

Sustainable Extricko

Founded: 2021

Location: Derbyshire, UK

Employees: 2

Origin: Independent start-up

Financials: £500,000 raised in funding to date

Additional information

Sustainable Extricko was a finalist in the Royal Society of Chemistry’s (RSC) Emerging Technologies Competition 2025, and is part of the RSC’s ChangeMakers deep tech chemistry support ecosystem.

No comments yet