Nanoplume’s bio-based materials are super-insulating but also cheap and scalable

Growing up, Theresa Hoffmann wanted to be an astronaut. ‘I’ve always been drawn towards space, and I was always excited about materials that could be used in space. The slogan at my university was “steel is the future”. And I thought: that can’t be it, there must be ways to develop more innovative materials,’ says Hoffmann, co-founder of Nanoplume.

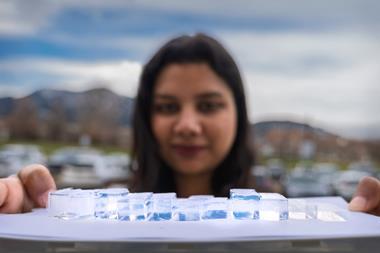

She has since coupled her fascination of space with her interests in circular materials to help make ‘space-age insulation accessible to all’. To do this, the team – including co-founders Tara Love and Tafadzwa Motsi – has created a bio-based aerogel that can compete with current insulating materials.

Aerogels have been known for the past 80 years, finding uses in specialist scenarios, such as ‘to insulate the Mars rover’, as Hoffmann notes. Such materials have extremely low densities and thermal conductivities due to their highly aerated nature, making them ideal insulators. Hoffmann explains that ‘there are some core problems with traditional silica-based aerogels’, including high cost, limited scalability and brittleness.

Nanoplume – based in Cambridge, UK – is instead using abundant resources, such as cellulose, in combination with other sugars and natural minerals, to create a more durable material, which doesn’t compromise on thermal efficiency. ‘By making [the aerogel] bio-based, we can also use a different process that is much cheaper and more energy- and time-efficient,’ says Hoffmann.

‘We are currently optimising the formulation, but we’ve already reached the super-insulating category for thermal conductivity.’ The material is completely non-toxic and is even safe to eat, as Hoffmann demonstrated at the RSC’s emerging technologies competition earlier this year, where Nanoplume won the energy category. Yet Hofmann explains that only high temperatures and humidity can break down the material, ‘so it won’t degrade in the operating environment’. Nanoplume is currently in the R&D stage, having run first trials with manufacturers to produce several panels of the material.

Heating and cooling account for nearly half of global energy consumption, contributing to more than 40% of global-energy related CO2 emissions. ‘The overall thermal insulation market is growing to be a $100 billion (£74 billion) industry by 2030, so there’s a variety of segments we are currently focusing on,’ explains Hoffmann.

Nanoplume’s initial target was cold-chain packaging, used to ship perishable goods such as pharmaceuticals and food. The team is currently partnering with a shipping company to integrate the material into shipping boxes, as a first whole-system test.

The team’s longer-term goal is to also target the built environment, to replace current wall, roof and floor insultation, in both new and existing builds. ‘To meet certain energy requirements, especially in the UK with future home standards, you would have to increase your wall cavities to continue to use traditional materials,’ explains Hoffmann. ‘We’re bringing a material that is much thinner and lighter so, in the end, you could just leave the wall cavity as is and use a higher performing material, like ours.’

‘[This material] is both a mitigation technology, because we’re increasing energy efficiency, but also adaptation, because we’re preparing humanity for increasing temperatures,’ says Hoffmann.

In the future, Hoffmann explains that the aerogel could also be used for numerous other applications, making use of the material’s highly porous nature in feminine hygiene products and to clean up oil spillages.

Nanoplume:

Founded: 2024

Location: Cambridge, UK

Employees: 4

Origin: Startup out of Carbon 13 sustainable venture builder

Financials: $1 million (£740,000) pre-seed funding

Additional information

Nanoplume won the Energy category in the Royal Society of Chemistry’s (RSC) Emerging Technologies Competition 2025.

1 Reader's comment