Biomass alkanes could fit into existing crude oil feedstock infrastructure

A new way for converting cellulose into liquid straight-chain alkanes may provide a viable alternative route to chemicals traditionally sourced from crude oil. With the demand for fossil-derived chemicals and fuels ever-increasing, making chemical building blocks using cellulose from the vast amounts of cheap, waste non-food plant biomass produced worldwide in combination with existing oil refinery infrastructure, could be an invaluable bridge to sustainable chemicals and fuels.

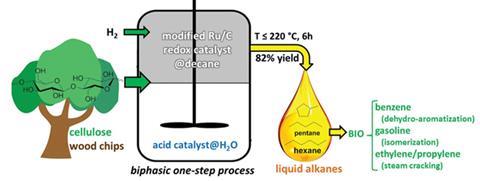

Bert Sels and co-workers at KU Leuven, Belgium, together with colleagues at the Leibniz Institute for Solid State and Materials Research in Germany, have designed an efficient process for making n-hexane and other alkanes that can then be turned into biofuels and bio-derived chemical building blocks. The one-pot process transforms cellulose derived from unpretreated sawdust using a ruthenium catalyst at around 220°C, into straight-chain alkanes (mainly n-hexane) in less than 6 hours. These relatively mild conditions are necessary to preserve the chemical bonds present in cellulose. During the process, oxygen is removed from the structure of cellulose leaving six C–C bonds intact in the cellulose structure. Sels explains, ‘the major challenge of this work is to remove oxygen without breaking the C–C bonds – breakage results in short, gaseous alkanes like methane and ethane.’

Sels aims to further process the bio-derived n-hexane feedstock into branched or cyclic forms of alkanes such as isohexane and dimethylpropanes that are currently used in fuels. ‘These chemicals may be produced in existing facilities using established process technologies,’ adds Sels, meaning that bio-derived feedstocks could be used immediately without modifying existing infrastructure. Intriguingly, he envisions that bio-derived n-hexane could replace crude oil-derived feedstocks to make other useful chemicals. ‘If you want to make bio-derived ethylene, propylene or benzene-then n-hexane is the best that you have. It is really interesting because there is no real large-scale process today synthesising benzene from a bio-resource.’

Richard Murphy, an expert in bio-based materials, and director of the Centre for Environmental Strategy (CES), based at the University of Surrey, UK, says ‘assuming this process can be scaled up from these laboratory studies under similar conditions and with sustainably sourced feedstocks there is every reason to believe that this innovative process can provide a reasonably low environmental impact route to renewable n-hexane.’ Murphy, who is also a lifecycle assessment (LCA) expert, adds that ‘process modelling of this at appropriate scale together with LCA to indicate economic and environmental profiles for potential fuel or chemical building blocks and beyond will be valuable extensions of these exciting findings.’

References

This article is free to access until 19 November 2014. Download it here:

B Op de Beeck et al, Energy Environ. Sci., 2014, DOI: 10.1039/c4ee01523a

No comments yet