Bespoke 3D-printed reactor makes use of greenhouse gas

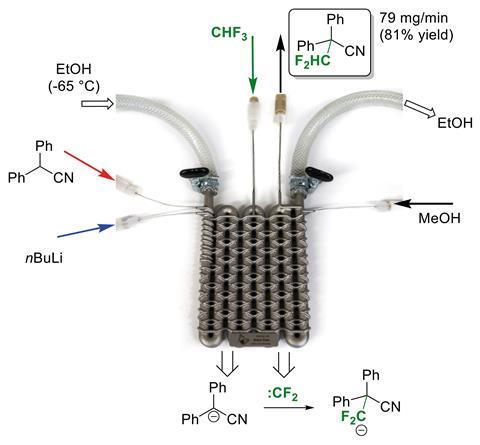

Researchers have 3D-printed a flow reactor out of stainless steel for performing a rapid exothermic reaction that turns a Teflon waste product into a synthetic building block.1

Led by Oliver Kappe at the University of Graz in Austria, the team made the metal reactor specifically to convert a known batch reaction – the difluoromethylation of a lithiated nitrile2 – to a scalable continuous process.

Fluoroform is a large-volume waste product from the production of fluoropolymers such as Teflon. While nontoxic and ozone-friendly, it’s also a greenhouse gas 11700 times more potent than CO2. Overcoming its very low reactivity for large-scale use in organic synthesis would reduce waste and pollution, but this requires harsh reaction conditions incompatible with polymer resins previously used to print bespoke reactors.

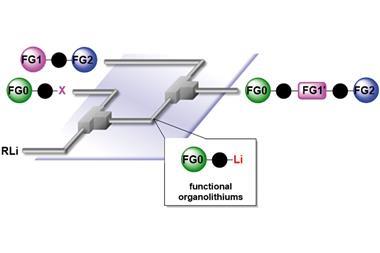

Instead, the team combined the flexibility of 3D printing with the high thermal conductivity of steel to make a flow reactor for a multistep nitrile lithiation and difluoromethylation with gaseous fluoroform. Including a cooling element in the reactor design made it possible to perform the process at cryogenic temperatures.

References

1 B Gutmann et al, React. Chem. Eng., 2017, DOI: 10.1039/c7re00176b (This article is free to access.)

2 K Aikawa et al, Org. Lett., 2015, 17, 4882 (DOI: 10.1021/acs.orglett.5b02438)

No comments yet