…but cutting production has to be part of the solution

The enormity of the challenge posed by plastic pollution is almost too much to grasp. At the risk of drowning readers in incomprehensible figures, here are some stats: plastic production has more than doubled since the turn of the century to an eye-watering 460 million tonnes each year – a figure that is predicted to double again by 2040. Over the last 70 years more than 10 billion tonnes of plastic have been produced – more than half of which has been made in the last two decades.

The vast majority of plastic waste ends up either in landfill or leaking into the natural environment – as highlighted by the recent spillage of 1.5 billion pieces of microplastic into the sea off the coast of Spain. With just 9% of plastic being recycled globally, perhaps it is unsurprising that plastic particles are now found everywhere on our planet, from the deepest ocean trenches to the upper atmosphere.

It’s clear that chemistry will play an integral role in our efforts to solve this crisis. In the long term, this means finding ways to replace current plastics with new polymers made from sustainable starting materials, and which can be more easily broken down at the end of their useful lives. In the more immediate future, we need to reduce our reliance on fossil-derived plastic and drastically improve our processes for recycling this material.

But recycling is itself a tricky challenge, due to the fact that the plastics in current use contain more than 13,000 different chemicals and are, by design, difficult to break down. A recent surge in petrochemical production in China and the US is adding to the headache for manufacturers of recycled plastic who cannot now compete with the low cost of virgin materials. And as Chemistry World has reported, recent studies have highlighted serious questions facing chemical recycling strategies that aim to break down plastics and convert them into new high-value products. Of the 11 current facilities operating in the US, the majority are producing low-quality fossil fuels and between them are barely making a dent in the mountain of waste that is generated each year.

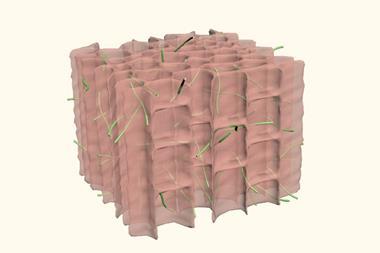

Other approaches that rely on more intricate chemistry to make products that won’t just be burned – including the ingenious polymer-editing techniques reported in our feature this week – are still in their infancy. While these methods might one day revolutionise the way that we think about plastic, it’s clear that reducing the amount of plastic that we use is the biggest step our species can take towards clearing up its plastic mess. UN-led attempts to agree a global treaty to end plastic pollution hit a stumbling block last year, when a group of countries with large fossil-fuel industries derailed negotiations by arguing that binding cuts to plastic production should not be in the treaty’s scope. The treaty text is due to be finalised by the end of 2024, suggesting that this year may be the most important yet in our efforts to halt this unfolding environmental disaster.

No comments yet