How organic chemistry powers the development of sustainable batteries

Over the last three decades, the demand for lithium-ion batteries has skyrocketed, driven by their widespread use in portable electronics, stationary energy storage systems and electric vehicles. Yet, despite their impressive performance metrics, their reliance on transition metals has started to stain their all-star reputation. Supply chain vulnerabilities, material scarcity and emissions from extraction and processing are all starting to surface, raising concerns about this powerhouse technology. The publication of the milestone article ‘Building Better Batteries’ by Michel Armand and Jean-Marie Tarascon in 2008 inspired many scientists to embark on a journey to enhance the performance of lithium-ion batteries and explore more sustainable battery chemistries.

One key battery component targeted for a sustainability makeover is the cathode, initially containing lithium iron phosphate (LiFePO4). However, in the late 2010s nickel manganese cobalt oxides (NMC) joined the competition by delivering higher energy densities. Since roughly 2020, with the return to the more stable LiFePO4, we are witnessing a move in the right direction, as supply chain risks associated with nickel and cobalt are avoided. However, LiFePO4 production still depends on polluting mineral extraction and energy-intensive processing, while its end-of-life recycling remains a major hurdle.

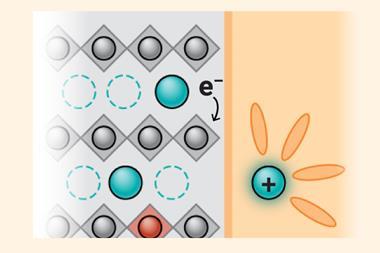

Organic cathode materials could be a great approach for a true green restyling. These materials can be sourced from biomass and consist of abundant elements such as carbon, hydrogen, oxygen, nitrogen and sulfur. Their molecular tunability, potential biodegradability and more straightforward recycling make these materials attractive candidates to help lithium-ion batteries regain their shine. Nevertheless, cathodes based on organic compounds often degrade or undergo dissolution after relatively few charge–discharge cycles, and suffer from low redox potentials that limit the battery’s voltage and energy output.

Fortunately, organic chemists possess a powerful synthesis toolbox to perform molecular modifications aimed at improving the performance of organic electrode materials during battery operation. In 2024, Alexandru Vlad’s group at the Catholic University of Louvain, Belgium, demonstrated this by addressing one of the hardest challenges in the field: synthesising high-voltage organic cathode materials.1

Exploiting electron-withdrawing effects

To do so, they chemically customised the p-phenylenediamine (p-PDA) redox molecule by converting the amine terminals to either triflimides or cyanamides via addition–elimination reactions (figure 1). These synthetic modifications lowered the electron density around the redox centre through electron-withdrawing and resonance effects, delivering high redox potentials of 3.2 V and 3.55 V (vs. Li/Li+) for the cyanamide (PDCA) and triflimide (PDFSA) derivatives, respectively. These values compare well to the redox potentials of LiFePO4 and NMC, at 3.4 V and 3.7 V (vs. Li/Li+).

To push the redox potential upwards, the researchers decorated PDCA and PDFSA with two chlorine or two fluorine atoms at the 1- and 5-positions, stripping the redox centre of even more electrons. Consequently, the oxidation potentials peaked at the impressive 3.7 V (vs. Li/Li+) for the difluorinated-PDFSA.

The potentials incrementally increased for decreasing electron densities when moving from the unsubstituted PDCA and PDFSA to the more electron-depriving di-chlorinated and di-fluorinated derivatives. However, battery testing of PDCA revealed an all-too-common obstacle in the development of organic electrode materials: dissolution.

Capacity constraints

Typically, p-PDA-type materials undergo a reversible two-step oxidation–reduction. While the first oxidation of PDCA to the radical intermediate happened flawlessly and reversibly, the second oxidation to the quinoneimine resulted in the feared dissolution, caused by the enhanced electrostatic attraction between the active material and the electrolyte. Limiting the electrochemical cycling to the first reversible one-electron process ensured a stable cycling performance, but resulted in a low full cell capacity of under 72 mAh/g, still far from the imposing 150-165 mAh/g capacity of commercial LiFePO4 batteries.

Nevertheless, this work shows how careful molecular design allows the fine-tuning of redox potentials to values close to those of LiFePO4 and NMC. Moreover, it offers a smart alternative strategy to methods commonly explored by scientists to prevent dissolution, albeit at the sacrifice of substantial specific capacity.

Another common strategy to prevent dissolution is the synthesis of polymer analogues. While this keeps the dissolution at bay, redox polymers often suffer from hindered conductivity and poor material utilisation, resulting in subpar capacities. Therefore, organic and polymer chemists have joined forces to develop covalent organic frameworks (COFs), currently a hot topic in battery research.2 Their tuneable pore sizes and potential incorporation of π-conjugated linkers might just charge these high-surface-area networks with the necessary structural integrity, electronic conductivity and material utilisation needed for high-performance batteries. The future will tell; nevertheless, it is clear that with chemical design at the heart of their development, organic chemistry is far from done in the journey towards sustainable batteries.

References

1. X Guo et al, Energy Environ. Sci., 2024, 17, 173 (DOI: 10.1039/D3EE02897F)

2. T Yang et al, Energy Mater. Adv., 2024, 5, 78 (DOI: 10.34133/energymatadv.0078)

No comments yet