Economics is central to invigorating the transition to a circular economy for plastic

Gary Anderson designed the recycling mobius loop logo in response to a competition held in 1970 by the Container Corporation of America. Contestants were asked to design a simple symbol for recycled paper. These days that symbol is everywhere. And these days, our domestic recycling bin is nearly always full – yet I find it hard to believe that it was only in July 2009 that my hometown expanded its kerbside recycling collection service to include cans and plastic bottles. Putting plastic in your recycling bin, however, does not guarantee that it gets recycled effectively.

Sorting mixed streams of plastic waste efficiently and accurately is an onerous but essential step for most recycling methods. The technology employed to sort this mish-mash of household refuse has now become surprisingly sophisticated. Hayley Bennett’s recent feature on ferrofluids revealed how a company in the Netherlands is using magnetic nanoparticles suspended in ferrofluids as part of a density-based sorting process. Sorting matters, because the higher the homogeneity of the waste stream the higher the chance of the polymers retaining their value when they are recycled.

Most polymer recycling is mechanical. Grinding up a plastic and melt-processing it into a new product does not alter the basic polymer. However, hydrolysis and transesterification reactions mean the polymers degrade with every cycle so cannot be recycled indefinitely using this technique.

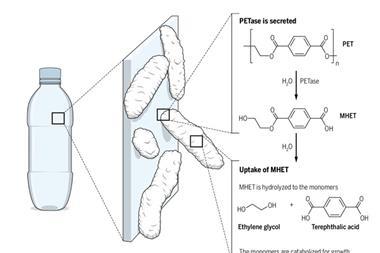

Chemical recycling – deconstructing polymers into monomers for use in another polymerisation reaction – can result in good quality products with high-end applications. Such processes are less established but present methods are energy-intensive and involve further processing down the line.

Then there’s upcycling plastic, which has the potential to be rather lucrative. In June, we brought you research that has successfully converted a plastic bottle into vanillin. Microbes engineered to have specific enzymes turn a near useless starting material into a chemical with superior economic value.

Creating a circular economy for plastics is never going to be simple. Radically reducing how much plastic we generate and consume in the first place has obviously got to be part of the equation. By finding ways to turn discarded plastics into chemicals and materials with a higher value, scientists are reframing society’s perspective on plastic waste. But let’s be realistic, plastic recycling must turn a profit. Earth’s plastic waste problem needs long-term solutions that can sustain themselves, as well as the planet.

No comments yet