High-energy compounds are needed to create more powerful and safer explosives. Sarah Houlton dons her hard hat to investigate

With the explosives store cupboard containing products as diverse as gunpowder, dynamite, TNT and modern plastic explosives like Semtex, one might think there are now plenty of ways of blowing things up, and nothing new is needed. But some explosives are toxic or environmentally unfriendly, and safer alternatives would be most welcome, as would those that are more stable in storage or with specific detonation properties. Research into energetic materials remains a fruitful field, albeit rather a niche and potentially dangerous one.

The inherent desire of nitrogen compounds to rearrange and form nitrogen gas is at the heart of much energetic materials research, and Karl Christe of the University of Southern California in the US is making pure nitrogen compounds and ions. Creating nitrogen allotropes is extremely difficult, he explains, not just because there are very few chemical reactions to make them, but because – of course – the materials are likely to be extremely energetic.

Until the late 1990s, the only such moiety known was the azide anion, N3–. Darpa, the US Defense Advanced Research Projects Agency, was interested in the potential of polynitrogen compounds for military purposes, and started to fund projects in the area. ‘Polynitrogen compounds would be revolutionary energetic materials, with very high energy release when they convert back to molecular nitrogen,’ Christe says. ‘They could significantly increase detonation pressures in explosives, and would have the extra advantage of being environmentally benign, as the only decomposition product would be nitrogen gas.’

Darpa funding enabled Christe to develop a synthesis for the cationic polynitrogen species N5+. ‘The cation was surprisingly stable up to about 60–70°C, and we created a dozen or so different salts.’ They also found spectroscopic evidence for a cyclic N5– anion. Although Darpa pulled the plug on its programme in 2004, the N5+ discovery sparked a lot of computational chemistry interest.

‘The literature was flooded with theoretical papers on polynitrogen compounds, but no-one has yet managed to make anything of real significance,’ Christe says. ‘It’s difficult. People don’t have the skills or the right starting materials, and if it’s more than a one-step reaction, the intermediates are likely to be highly unstable, and there are no known reactions to make intermediate polynitrogens. Two Nobel prizes have been won for carbon allotropes – buckyballs and graphene. To make a nitrogen allotrope is several degrees more difficult!’

All nitrogen, all the time

The search for a nitrogen allotrope continues, fuelled by theoretical calculations. Back in 2002, for example, Rodney Bartlett at the University of Florida, US, predicted that N5+N5– should be a stable crystalline salt. Earlier this year, Benny Gerber of the Hebrew University in Jerusalem, Israel, published calculations predicting crystals of N8 to be stable at low temperatures, with two N8 units held together by weak van der Waals interactions. Each N8 unit itself is predicted to be rather unstable, decomposing to two N3 radicals and N2, with a low activation energy barrier of only 8 or 13 kcal/mol, depending on the N8 isomer chosen. But experimentally made, kinetically stable nitrogen allotropes remain elusive.

Peter Portius is investigating nitrogen-rich compounds in his lab at the University of Sheffield, UK, working with energetic nitrogen-rich and nitrogen-only ligands, such as three-nitrogen linear chain azido groups, and coordinating them to light elements including silicon, germanium or phosphorus. ‘This can result in novel complexes of several azide ligands held together by a single coordination centre – one non-nitrogen atom, surrounded by many nitrogens,’ he says. ‘It is really exciting to explore the limit of nitrogen content at which nitrogen-rich compounds can still be isolated, and synthesise these compounds in a Schlenk tube.’

His group uses synthetic chemistry in combination with a whole range of analytical techniques, such as ultra-fast time-resolved laser spectroscopy, to shed light on the molecules’ stability. ‘Stability embraces issues such as impact, friction, electrostatic discharge and thermal sensitivity,’ Portius says. ‘For nitrogen-rich compounds, decomposition can be triggered very easily, partly because their N–N bonds are weak, and the N–N triple bond in dinitrogen is strong. The energy difference between those two bonding modes for nitrogen means these compounds have promise in energy storage.’

High-nitrogen molecules

Some of the most fascinating work in the energetic materials field is being done by Thomas Klapötke at the Ludwig-Maximilian University of Munich in Germany. Many of the molecules he and his group have made look extremely unlikely on paper – to most chemists, they look inherently unstable, and exothermically so.

That doesn’t daunt him, though. He is interested in anything that could be classified as an energetic material, whether that is as a primary explosive, a secondary explosive, a gun propellant or a rocket propellant. ‘We also have some interest in pyrotechnics, which are energetic materials but not explosives,’ he says. ‘The main reason for the work is to provide the armed forces with better materials. ‘Better’ could be seen in terms of performance, or reduced sensitivity that makes them safer to handle, or lower toxicity.’ But if sensitivity and toxicity are reduced at the expense of performance, the material is unlikely to be used. ‘It may be nice for a publication, but in the real world, if it doesn’t shoot as far, forget about it,’ Klapötke adds.

About 15 years ago, Klapötke started to look at high-nitrogen compounds – defined as those that are at least 65% nitrogen. ‘They can be beautiful as ingredients for gun propellant chargers, but for high explosives they don’t have that final bit of energy to oxidise the remaining 10% of the molecule if they are 90% nitrogen,’ he explains.

So five or six years ago his focus shifted slightly to high-nitrogen compounds that are also oxygen rich. They may contain nitro groups or N-oxides, with the oxygen helping to oxidise the remaining carbon or hydrogen, converting it to carbon monoxide and water, and delivering an exotherm. N-oxides also increase the polarity of the molecule, which gives the energy a further boost via increased molecular interactions making the density higher, Klapötke says. ‘Detonation velocity scales with density, and detonation pressure, which is even more important, scales with the square of the density. So the higher density the better.’

He’s published the structures and syntheses of numerous of these at-least-two-thirds-nitrogen N-oxides and nitro compounds. A couple have made it into smaller-scale technical scale-up at Ardec, the US Army’s Armament Research Development and Engineering Center at Picatinny Arsenal in New Jersey, where they are being synthesised at a kilogram-scale for test formulation purposes. ‘They are mixed with binders and plasticisers to see how they behave in real weapon systems,’ he says.

Primary problems

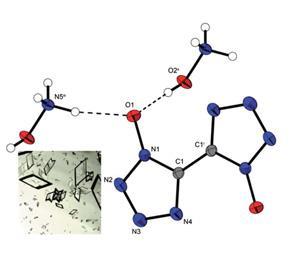

In the high explosives arena, Klapötke’s compound TKX-50 (dihydroxylammonium 5,5’-bistetrazole-1,1’-diolate) was developed in collaboration with the US Army Research Laboratory at the Aberdeen Proving Ground in Maryland. It is made via tetrazole oxide chemistry, and not only is it easy and cheap to synthesise, but it is also a powerful explosive that is thermally insensitive, safe to handle and has low toxicity. ‘The US army is now scaling it up to 20kg batches to evaluate it further, and I hope it may one day make it into a real application,’ he says.

The majority of primary explosives – those used to detonate larger quantities of less sensitive explosives – involve lead azide or lead styphnate. They work well and are cheap, but the lead renders them toxic. Shooting once in action is not the problem – the real issue is at firearms training grounds, where lead will slowly accumulate, having a long-term impact on the environment and the people who work there full-time. ‘We recently published a potassium-containing compound that has similar properties to lead azide,’ Klapötke says. Potassium 1,1’-dinitramino-5,5’-bistetrazolate, or K2DNAMT, is more expensive but much safer, and could be used as a replacement for lead-based primers, particularly in applications where lead accumulation is a real hazard.

Christe is also looking for lead azide replacements, and has made at least 30 different polyazides in his search. Commercially available trimethylsilyl azide, which is not shock sensitive, is reacted with metal fluorides to give, in a one-step, quantitative reaction, a range of polyazide salts, including oxoazides and nitrodoazides. ‘Some are very explosive, some very sensitive, but others are sufficiently stable to be of interest in the explosives area,’ he says.

Avoiding the downsides

Safety is a key concern when making energetic materials. There is no getting around the fact that they are explosive – if they were not thermodynamically unstable, they would not release energy upon reaction or combustion. The ideal energetic material must have a sufficiently high activation energy barrier towards reaction or decomposition to allow its safe handling, but be able explode if sufficient persuasion is provided.

Standard procedure is now to run computer simulations before making new molecules, and many performance parameters can be calculated reliably. Calculated entropies of formation and densities can be used to predict detonation velocity and pressure, plus the temperature of explosion. ‘If we have an exotic molecule that may take five weeks to synthesise, we can predict whether it will perform better or worse than TNT, and decide whether it is worth making,’ Klapötke says. ‘Sensitivity levels are much more difficult to predict – you still have to make things in the lab to see how safe they are to handle.’

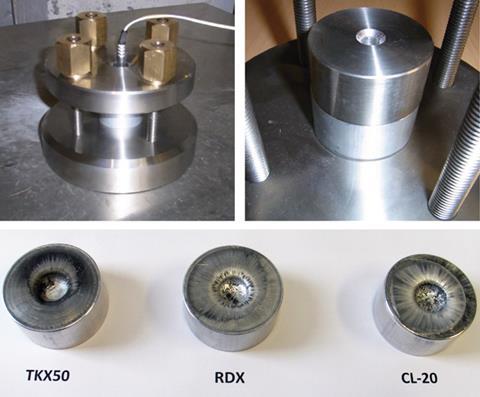

Klapötke is keen to point out that they are deliberately synthesising compounds for the army that are designed to be lethal. ‘We don’t know how sensitive or dangerous a new compound will be, and this is why we do the first prep on a scale no greater than 250mg. We can then very roughly evaluate its impact friction and electrostatic sensitivity,’ he says.

If the properties are promising, they’ll scale up to 0.7g and repeat the safety tests on grains to get more accurate, reliable numbers. If these remain good, then they scale up to 2.5g, then 5g, then 10g, with further safety evaluations each time; if something is unstable at 2.5g it will be of no practical use at a larger scale. ‘We never make more than 10g in one batch,’ he says. ‘Even if we need 50g for detonation velocity tests, we would do five 10g preps.’

As well as the quantity rule, self-protection is also essential. ‘You have to be very cautious when working with these materials,’ Christe says. ‘Because they can release a lot of energy very quickly, you have to protect yourself, with leather or Kevlar clothing, heavy gloves, face protection and earplugs.’

If materials have a high electrostatic discharge sensitivity, the equipment and fume hood will both be grounded, as will the chemist, Klapötke adds – conducting shoes on conducting floors. ‘Operations like pressing materials into tablets are done via remote control in a bunker with a closed door so if anything goes wrong it can’t harm the chemists.’

In a field where one accident that causes injury can be sufficient to close down operations completely, these safety steps are vital. Christe, for example, twice had a forced change of job when accidents in other labs caused his employers – Stauffer in 1967 and Rocketdyne in 1994 – to abandon energetic materials research.

Despite careful precautions, small accidents still happen, Klapötke says. Sometimes compounds can go bang without any stimulus at all – they can sit on a filter paper and explode unexpectedly. ‘Fortunately, this does not happen very often, and we have only had one bad accident during my time in Munich,’ he says. ‘That was the first, and I do not want to see it again. Absolute safety is not possible – whatever you do in life, there is some risk, and the risk will always remain when working with explosives that injury may happen. I was injured earlier in my career, and wear a hearing aid as a result. Nothing is 100% safe, but if no-one invents new molecules, we will never find anything better.’

Of sulfur and selenium

While a lot of the focus has been on nitrogen–oxygen compounds, a move down the periodic table reveals that sulfur and selenium compounds with high nitrogen content are also somewhat energetic. The binary sulfur nitride S4N4 is well known, with an unusual cradle-shaped structure. The gold-coloured crystals are air stable, but are also somewhat frisky and shock-sensitive, and readily decompose to solid sulfur and nitrogen gas when ground; the purer they are, the more unstable.

Other S–N compounds are even less easy to work with; S5N6, for example, is very air sensitive, so a glovebox is required and ground glass joints must be avoided. Yet there are examples of S–N anions and cations that are very stable, perhaps because lattice energy contributes to their stability, explains Paul Kelly from the University of Loughborough, UK.

Dropping further down to selenium, Se4N4 is also fairly inert when left alone and impure, but Kelly, who has made the stuff, explains that when it’s very pure simply touching it with a spatula is sufficient to make it explode. ‘If it’s not quite so pure, there is more leeway, but we never weighed it out as a solid – we’d transfer it as a suspension, letting it settle and dry out,’ he says. ‘This is virtually the only binary selenium–nitrogen compound known, and it’s very difficult to handle.’

While S2N2 can be used as a precursor to stable (SN)x, and Kelly spent many years trying (and succeeding) to make the selenium analogue, the instability of small molecule high-nitrogen compounds of sulfur or selenium generally rules out practical applications. But Kelly believes we still don’t know enough about the chemistry of main group elements like sulfur and selenium. ‘What happens when we have this element in combination with another? What can it do?’ he says. ‘That’s what we were trying to do with the selenium nitride chemistry.’

No comments yet