Where would we be without our glassware? Tabitha Watson looks through the history and current state of chemistry’s favourite amorphous solid

Chemistry has a heart of glass. Think of chemistry and images of sleek laboratories filled with glittering glassware come to mind; ask a chemist what they couldn’t survive without, and the answer will probably be made of glass. Glass is part of chemistry’s identity and history, so how did it become such an essential part of the lab?

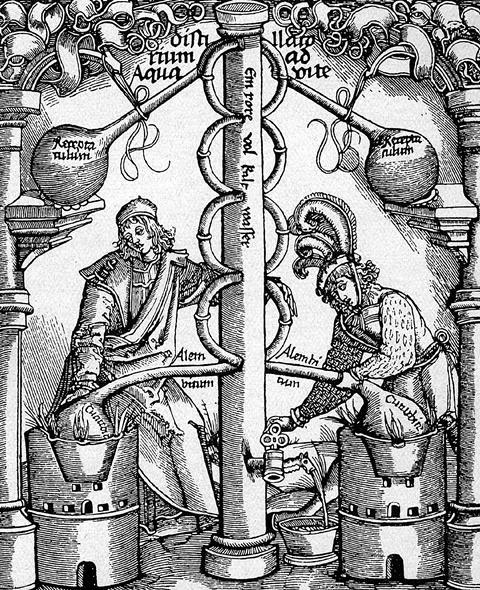

The earliest examples recognisable as ‘scientific’ glassware come from the alchemists’ laboratories of Hellenistic Egypt. These early experimentalists prized glass for being inert and transparent, making it the natural choice for conducting their experiments. Johann Glauber, a prominent alchemist in the 1600s, is thought to have conducted many of his experiments in the furnace of the Rozengracht glasshouse, and his knowledge of raw materials and their purification is often considered an essential part of the development of glass during the Baroque era. But glass chemistry had already come a long way before alchemists brought it into the lab.

‘If you go back to the beginnings of glass, at around 4000BCE, the composition was defined by the fact that it has to include some sand and some silica,’ says John Parker, professor emeritus of glass science and engineering at the University of Sheffield in the UK. ‘However, silica melts at far too high a temperature for anyone to get there using a wood-fired furnace.’ Ancient glassmakers therefore had to rely on impurities to lower the melting point – they realised that adding compounds such as soda salts, which were readily available due to their use in dyeing and laundry, did the trick.

Yet that’s only part of the story. ‘If you had sodium carbonate and pure silica, you could make a glass … but it would be water soluble. You need to have something in the glass that improves the chemical durability ,’ Parker continues. By happy accident, when the glassmakers were gathering sand from river estuaries around the Mediterranean basin they were also collecting that crucial third ingredient: limestone.

Limestone increases the viscosity of the material by increasing its crystallinity, causing it to become more durable and resistant to chemical wear. Soda–lime glass remained the state of the art for hundreds of years.

The next step came in 1500BCE, with the first hollow glass containers. ‘Glassblowing was something the Syrians introduced,’ says Parker. ‘In fact, Aleppo, which you will have heard of in other contexts, was a very famous glassblowing centre.’ When Syria was annexed by the Roman Empire in 64BCE, these skills would have been rapidly shared.

Glass blows up

Chemists had the material they needed, and the skill to work with it, and the shapes of modern glassware began to emerge. Soda-lime glassware housed much of chemistry’s development up to the late 18th century, with chemists increasingly creating their own designs. ‘If you look at William Ramsey, or even if you go way back to Berzelius in the early 19th century, they, and all of their contemporaries, were phenomenal glassblowers,’ says Andrea Sella, a professor at University College London in the UK and regular contributor to Chemistry World through his Classic Kit column. ‘Berzelius in particular invented and made loads and loads of bespoke glassware himself, the designs of which are still used today.’

‘By the early 20th century, a lot of the standard shapes had been established. If you look back, some shapes are really ancient,’ says Mallory Warner at the Smithsonian National Museum of American History. ‘Something like a retort has a really long history, but if we look at the work Joseph Priestley was doing in the 1700s, I wouldn’t say he had, aside from the retort and certain bell-jars, much ‘modern’ equipment. Some things would have been very similar to the things that we currently know, but he would also be using items from places like his kitchen. In his letters, he talks about using beer glasses to trap mice. So, definitely in that time period in the 1790s, at least for Priestly, some of the shapes are familiar but the standards weren’t always there.’

Another persistent issue was the composition of the glass itself was still governed by whatever raw ingredients were to hand, leaving many of its properties up to chance. For example, a common problem with soda-lime was its inability to survive thermal shock or chemical attack. ‘Up until the late 19th century, soda glass was the only game in town,’ says Sella. ‘Until sometime around the 1870s, when Ernst Karl Abbe realised that you needed a superior kind of glass to make better optics.’

‘Abbe came to London and gave one hell of an important speech. He basically made a plea to glassmakers, saying that they needed to develop new sorts of glasses instead of focusing on making better window glass. This was picked up by a young chemist by the name of Otto Schott.’

The advent of borosilicate glass is one of the critical milestones in the advancement of chemistry

After Abbe’s rousing speech, Schott went away and systematically produced glass with every conceivable oxide additive he could think of. If a glass contains too much soda, it can be easily attacked and dissolved by water. However, if there is a suitable amount of a stabilising oxide, the glass becomes more durable. ‘He essentially explored composition space like mad,’ explains Sella. Once he had investigated every nook and cranny of glass composition, he passed all of his samples on to Abbe who in turn gave them to his colleague, Carl Zeiss, to manufacture the best lenses in Europe.

In the process, Schott happened on a glass that could stand up to much more extreme chemical and physical conditions than anything seen before: borosilicate. ‘In my opinion, the advent of borosilicate is one of the critical milestones in the advancement of chemistry, because you have glassware that can take much more ferocious chemical conditions than previously, it’s more chemically resistant, you can shove a Bunsen burner under it and it won’t smash,’ Sella says. Schott swiftly realised that borosilicate was the best glassware for laboratories and he patented it under the name Duran.

The key to borosilicate’s superiority lies in its purity. While soda-lime is made of approximately 69% silicon dioxide, borosilicate is composed of over 80% silicon dioxide. The main type of impurity in each glass is also different. The fact that borosilicate contains a greater proportion of boron trioxide than soda-lime and significantly less sodium oxide means that its chemical structure is bound together much more tightly. This makes the material much less likely to expand in the presence of heat, lowering the chance of thermal shock.

The borosilicate revolution

Borosilicate glass hasn’t been bettered. ‘We continue to use borosilicate glass in the lab to this day, and it’s the stuff that glassblowers work with,’ says Sella. ‘It’s far easier to work with because you can take the temperature higher – it has a much smaller thermal coefficient of expansion, so you can heat and cool it and it doesn’t crack.’

‘[Glassblowers] use borosilicate because of its relative purity,’ says Gayle Price, scientific glassblower at the University of Leicester. ‘It’s a good compromise,’ she continues. ‘You’ve got your soda-lime which is quite cheap but isn’t very resistant to things like thermal shock or chemical attack. Borosilicate is a lot better as it’s much more resistant. The next one up would be quartz glass or pure silica – you can’t thermal shock that – but it also melts at such a high temperature it’s difficult to work with, and because it’s so pure it’s very brittle.’

With a more robust glass, chemists could explore new reactions and conditions. Borosilicate also brought a significant change to the availability of scientific glassware; manufacturing soon became industrialised, and today the majority of glassware is available off the peg.

‘Mass production was of course a huge change,’ Warner continues. ‘It came about at the end of the 19th century, along with standardisation. Right around the same time that mass production was happening, there was also a really increasing demand for scientific glassware. The demand rose across chemistry, medicine and standardised testing agencies.’ As reliable, standardised glassware became more readily available, they enabled more accurate analytical procedures, such as the Babcock test, used to ensure milk quality. The Babcock test really required standardised volumetric glassware in order to work, as did many other similar tests. Standards in oil were also being investigated at around the same time, so this fuelled the demand for high-quality volumetric glassware.

‘Automation has completely transformed the manufacture of glassware,’ agrees Sella. ‘Until about 25-30 years ago, when I was a student, it was normal for a graduate student to at the very least learn how to cut glass, join pieces of glass together and conduct simple repairs, that sort of stuff. All chemistry departments had glassblowers, and loads of things such as vacuum lines were made by the glassblower on demand. However, it’s a real privilege to have a glassblower in a department nowadays.’

Two decades of glassblowing

Gayle Price has been working in glassblowing since the late 1990s. She was trained by William McCormack at Glasgow University and helped to reconstruct the glassblowing facility at the University of Hull after a disastrous flood in 2007. She joined the University of Leicester in 2012. She has seen quite a few changes in the 20 years of her career so far.

‘The glass now is a lot more uniform: wall thicknesses are a lot more uniform, there are fewer impurities and flaws in the glass – it’s a lot nicer to work with. Large scale industrial production is a lot more precisely controlled so it gives you a more consistent quality,’ she says. ‘Sometimes I get quite old glassware in for repair, and it’s very thin in the wall and there are striations and air bubbles so it’s a bit of a pain to work with.’

I think glass will continue to be at the forefront of scientific discoveries

Industrial production methods have improved more than just the uniformity of glass thickness, however. ‘Things like stopcocks used to be ground down by hand and individually leak tested so they were a lot more expensive,’ Price explains. ‘These things can be made on such a large scale now, and they’re kind of just as good – if not better, because they are so consistent.’

Beyond the glassware itself, the way in which glassblowers and chemists work together has changed too. ‘Nowadays I’m being asked to do a lot more custom stuff. I’m getting a lot of people coming in from outside companies, because glassblowers are becoming a bit thin on the ground,’ she says. ‘It’s no longer just the university I’m working for now. I’m not sure if it’s so much the quality of the glass that’s pushed those changes, as it is the rarity of the glassblower.’

Working alongside chemists for so long, Price has noticed changes in the way they work too. ‘It’s gone a bit more towards sustainability; making things more environmentally friendly,’ she says. ‘I’m being asked to do a lot more reusable things, and to work on stuff that’s been found in the cupboards – they ask “Could you change this? Could you add that?”’

But is there anything on the horizon that could knock glass from its position as the chemist’s best friend? Price isn’t convinced. ‘You can get metal vacuum lines which go down to far greater vacuum, but you also get memory effects. They’re not as easy to clean and metal is a lot more reactive than glass so there are certain things that you can’t do. Arguably glass is superior, as you can clean it, you can see what’s going on and observe any changes. I think glass is, and will continue to be, at the forefront of scientific discoveries.’

Automatic for the people

In Price’s opinion, automation means jobs like hers have become more specialised. ‘A lot of basic glassware can all be mould blown and shipped out for a fraction of the cost and time and effort than it would be for someone like me to maybe make one on a lathe,’ she comments. ‘You don’t have to learn how to blow a round bottomed flask because you can just take one off the shelf.’

To some, the result of this seems to be is a slight metamorphosis into something a touch more impersonal. ‘Before mass production I think you had more of a connection with your equipment, which I think now people have less of,’ says Sella. ‘It’s almost disposable now. If you look at the amount of garbage that comes out of a chemistry department, it’s pretty shocking. This is a classic evolution in science, in that science has shifted from being a very sensual activity where you smelled it, you tasted it, you built your own kit, to something more automated and almost clinical. In an era of push-button boxes and disposable glassware, I wonder whether that emotional connection with your kit is changing. It’s not for the better, it’s not for the worse; it’s different.’

Yet while the shapes of chemical glassware aren’t likely to change, the same cannot be said of its chemical composition. ‘Improvements in glass just continue all the time, and that’s because people have ever more finicky requirements for this and that and so end up putting in a smidge of this additive or that additive,’ says Sella.

‘I hesitate to say that the problems of chemical durability have been solved,’ Parker continues. ‘One of the big issues at the moment is putting ultra-sensitive drugs into glass ampules. Even small changes in pH or interactions could destroy their efficacy, and although glass is, in many ways, more chemically durable than plastics, compounds do leach out from some glasses. There’s a lot of work going on at the moment to try and avoid that sort of interaction.’

‘Glass is such a wonderfully versatile material, and it has been so instrumental in all science,’ says Price. ‘There’s definitely a symbiotic relationship between chemistry and glass,’ she continues. ‘There’s a lot of things that wouldn’t have been possible without glass. When you consider how old glass is and how advanced we are now, we still haven’t found an adequate substitute for it in thousands of years and that doesn’t look like changing any time soon. I think, if it wasn’t for glass, science wouldn’t be at the stage it’s at now. It would have gone in a very different direction. By the same token, without understanding the nature of glass and its chemical composition and structure, the glass wouldn’t be such fantastic quality and it wouldn’t be good enough and trustworthy enough. The two things are inextricably linked.’

Tabitha Watson is a science writer based in Leicester, UK

2 readers' comments