Ionic liquids have flowed far and wide since they first bubbled to the surface in the late 1990s. Michael Freemantle reports

Twenty years ago, ionic liquids were a remote backwater of chemistry. Few chemists were interested in these salts with organic cations that melted at low temperatures. At the time, just a trickle of papers featuring ionic liquids appeared in scientific journals. The 1980s and early 1990s saw no more than 25 scientific publications on the topic each year.

That began to change at the turn of the century. In 1999, the Queen’s University Ionic Liquids Laboratories (Quill) research centre, opened in Belfast, Northern Ireland. The following year, chemists and chemical engineers from around the globe gathered in Heraklion, Crete, to attend a Nato advanced research workshop on green industrial applications of ionic liquids. It was the first ever international meeting devoted to ionic liquids, Quill co-director Kenneth Seddon observed at the meeting. The workshop attracted virtually every active ionic liquids researcher in the world, a mere 65 researchers.

There followed an explosion of interest in the subject. Over 400 participants from 33 countries attended the First International Congress on Ionic Liquids, held in Salzburg, Austria, in June 2005. The number of publications on ionic liquids that year was around 1500. By 2013, the annual number of publications had soared to over 6000, with the total ionic liquids literature comprising in excess of 46,000 publications. Furthermore, the total number of patents based on ionic liquids increased from about 500 in 2005 to around 12,000 in 2016.

Green, but how green?

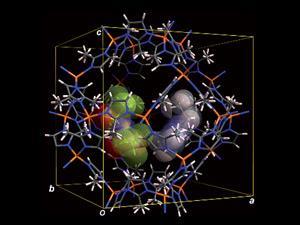

The past two decades have also seen a phenomenal rise in the number and variety of ionic liquids reported in the literature. The ions of the salts come in many shapes and sizes. Their cations are typically organic ions containing nitrogen, phosphorus or sulfur. The anions are mostly inorganic, although organic anions such as acetate have featured increasingly in recent literature.

As their melting points are generally less than 100oC, the salts have sometimes been called room-temperature ionic liquids. In the late 1990s, they attracted attention as ‘designer solvents’ because their chemical, physical and biological properties could be tailored by changing their cations or anions. The salts have, for example, a wide range of miscibilities and solubilities. Some are hydrophilic while others are hydrophobic.

Ionic liquids tend to be non-flammable and many are also thermally stable at temperatures higher than conventional molecular solvents. And unlike molecular solvents, ionic liquids have low vapour pressures and can be readily recycled. For these reasons, they were also known as ‘green solvents.’

But as interest in the salts grew, so did concerns about their green credentials. Many early investigations, for example, focused on ionic liquids with fluorinated anions, notably those with tetrafluoroborate (BF4–) or hexafluorophosphate (PF6–) anions. In 2003, ionic liquids with these anions were shown to undergo hydrolysis leading to the generation of highly toxic and corrosive hydrogen fluoride. Ionic liquids with the fluorinated anions bis(trifluoromethylsulfonyl)imide, [NTf2]–, and trifluoromethanesulfonate, [OTf]–, were also widely studied.

‘We’ve mercifully moved away from the BF4–- and PF6–-based ionic liquids,’ comments chemical engineer Jason Hallett at Imperial College London. ‘We moved first to [OTf]– and [NTf2]– but now have moved away from fluorinated anions almost completely. This greatly opens up the field of ionic liquids and also makes way for a more eco-friendly set of solvents.’

The possibility of producing ionic liquids from renewable sources is currently attracting attention, notably at the Joint BioEnergy Institute (JBEI), one of three US Department of Energy Bioenergy Research Centers that focus on the science underpinning the production of cellulosic biofuels such as bioethanol. JBEI researchers have synthesised ionic liquids, dubbed ‘bionic liquids,’ consisting of tertiary amine cations and dihydrogen phosphate anions. The tertiary amines are prepared from aromatic aldehydes produced from lignin and hemicellulose. These are two of the three major components of lignocellulosic biomass, the other being cellulose, and they are both by-products of the production of biofuels from plant biomass.

Industrial interest

Ionic liquids seem to have penetrated virtually every nook and cranny of pure and applied chemistry. They have been studied and used as solvents, catalysts, reagents and materials themselves. An intriguing array of potential applications includes their use as lubricants for offshore wind turbines, hydraulic fluids, thermal fluids for heat transport and storage – not to mention rocket fuel and embalming fluids. And because of their ionic nature, research groups throughout the world are seeking to exploit their electrochemical properties. Applications reported in the literature include their use as electrolytes in fuel cells, solar cells and batteries, as gas sensors and in electrodepositing metals.

The seemingly endless list of ionic liquid applications has inevitably attracted the attention of industry. As early as 2002, the German chemical manufacturer BASF began operation of its ‘biphasic acid scavenging utilising ionic liquids’ (Basil) process in which a 1-alkylimidazole is used to scavenge acid by-products generated in organic processes such as esterifications. The scavenging results in the formation of an ionic liquid which is then separated from the product by liquid–liquid phase separation. The ionic liquid is then recycled following deprotonation. The process handles ionic liquids on a multi-ton scale and is used for the routine production of alkoxyphenylphosphines. These compounds are raw materials for the manufacture of photoinitiators that, when exposed to ultraviolet light, initiate the polymerization of unsaturated components in coatings, adhesives, and printing inks.

BASF also launched its Basionics range of ionic liquids that year. They are mainly 1-ethyl-3-methylimidazolium salts. ‘They are used as additives for coatings, adhesives, moulding compounds and foams, for example in antistatic finishing of safety shoes, and in the production of floor and furniture care products,’ says Tatjana Levy of BASF’s specialty intermediates marketing division.

In 2015, another German chemicals company, Evonik, demonstrated in a pilot plant that a catalyst system with an ionic liquid supported on a solid could work reliably for around 2000 hours. Such systems are known as supported ionic liquid phase (Silp) materials. Evonik’s system had an ionic liquid consisting of imidazolium cations and amine-based anions, and a homogeneous catalyst. The company used the system to carry out hydroformylations, used in industry to produce aldehydes from syngas (hydrogen and carbon monoxide) or alkenes.

Silp materials are also proving their worth in gas purification. For example, the Malaysian national oil and gas company Petronas collaborated with a team at Quill to design an ionic liquid-based process that scrubs mercury vapour from natural gas streams. Mercury is a well-known health and environmental hazard, and also a strong catalyst poison and a corrosive that can damage gas processing equipment such as aluminium heat exchangers. Work on the ionic liquid technology began at Quill in November 2007 and was taken from a laboratory gram-scale process to full-scale industrial operation in four years.

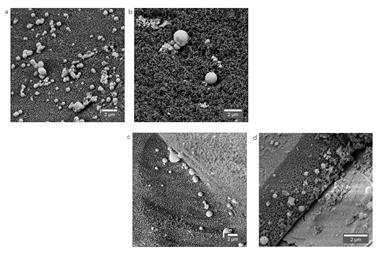

The technology, known as HycaPure Hg, employs an ionic liquid/copper(II) chloride Silp system. Commercial-scale operation of the process began in November 2011 when tons of the Silp material were loaded into mercury removal vessels at a Petronas gas processing plant in Malaysia.

‘The Hycapure-Hg scrubbers have proved a success,’ comments chemist John Holbrey, a member of the Quill team. ‘One of the biggest challenges in this field now is the reduction in the footprint of mercury removal units so that systems can be effectively deployed offshore on oil and gas rigs and floating liquefied natural gas vessels where space is at a premium.’

Another Quill project illustrates the immense diversity of potential ionic liquids applications. Chemist Nimal Gunaratne and colleagues demonstrated that ionic liquids can be exploited in perfumery. The Quill team treated the ionic liquid 1-methyl-4-formylpyridinium iodide with fragrant alcohols in the absence of a solvent. One of the alcohols was 2-phenylethanol, which smells of roses and is a common ingredient of perfumes. The ionic liquid and alcohol combine to form a pro-fragrant ionic liquid matrix. ‘Water triggers release of the perfume from the matrix,’ explains Gunaratne. ‘These ionic liquids might also be used as deodorants because they are also able to scavenge the unpleasantly smelling thiols in sweat while simultaneously releasing a perfume. Our group is currently in the early stages of consultation with a French perfume company to develop the pro-fragrances.’

Biomass conversion

The possible use of ionic liquids for the conversion of biomass into biofuel and useful chemical products and in particular the fractionation of wood into its major components – cellulose, hemicellulose and lignin – has become a major focus of current ionic liquids research not only at JBEI but also elsewhere.

Ionic liquids can dissolve cellulose, and some containing imidazolium ions can dissolve wood itself, potentially allowing for selective precipitation of its components. The selective extraction of hemicellulose and lignin from wood using ionic liquids has also been reported. However, the homogenous dissolution of wood under mild, that is non-degradative, conditions and the selective precipitation of its different components remains a significant challenge. Earlier this year, chemist Alistair King and colleagues at the University of Helsinki revealed that it is possible to overcome this problem by applying autohydrolysis, essentially hot water extraction, to pre-treat wood. ‘This allows us to dissolve even wood chips, a low-cost feedstock, in ionic liquids, whereas previously wood required harsh and expensive mechanical pulverisation to dissolve at all,’ says King. ‘In our opinion this is a significant discovery as there is now potential to use wood chips as low-cost polymeric feedstock.’

Hallett and co-workers have been looking into the use of ionic liquids not only to extract lignin from wood and but also to depolymerise the lignin to produce aromatic compounds. ‘The high cost of most ionic liquids, however, is a significant and frequently cited disadvantage that stands in the way of many commercial applications, not least lignocellulosic biomass conversion,’ says Hallett. Ionic liquids are generally many times more expensive than conventional molecular solvents. Hallett’s group has used process models for manufacturing ionic liquids to show that some ionic liquids are not so expensive when produced in bulk. In particular, the cost of ionic liquids containing the [HSO4]– anion, triethylammonium hydrogen sulfate and 1-methylimidazolium hydrogen sulfate for example, compares favourably with organic solvents such as acetone and ethyl acetate. ‘They are now cheap enough for large scale applications such as carbon capture and fuel purification,’ adds Hallett.

Wearable biomedical sensors

Healthcare has felt the spread of ionic liquids science and technology. Earlier this year, chemical engineer Wenlong Cheng at Monash University, Australia, and colleagues described the fabrication of low-cost, lightweight, rubber-band-like, waterproof biomedical sensors that incorporate ionic liquids. The sensors can be worn around the wrist to monitor body movements. Making it involved a mould and a silicone material to generate an elastomer film with microchannels. The group then poured the ionic liquid 1-methyl-3-octylimidazolium chloride into the microchannels and finally sealed the film with another layer of the elastomer.

Our ionic liquid-based sensor can accurately identify wrist pulses

Wenlong Cheng

The sensors rely on the piezoresistive effect. Body movements displace the electrical charges and therefore the resistance in the ionic liquid. Each body movement results in a unique variation in resistance. These variations can be picked up wirelessly and transmitted to a device such as a smartphone.

‘The sensors could be printed, drawn, dip-coated onto various substrates or even directly on human skins,’ says Cheng. ‘Despite the simplicity of their fabrication, the sensors show outstanding performance, including tuneable sensitivity, detection of a wide range of strains, high durability, and excellent long-term stability under both low and high strains. We further show that our ionic liquid-based sensor can accurately identify wrist pulses, and can be woven with commercial rubber bands into colourful bracelets for hand gesture detection.’

An ionic way of thinking

The possible use of ionic liquids to prepare new forms of active pharmaceutical ingredients (APIs) and assist in their delivery to the body is another exciting area of research. In 2007, an international team of researchers that included chemists Robin Rogers at the University of Alabama, US, and James Davis Jr. at the University of South Alabama described an approach to combine the pain reliever lidocaine hydrochloride and the emollient sodium docusate.

More recently, Rogers, who is now at McGill University in Canada, Davis and co-workers prepared clear liquids that flowed freely at less than 100°C by grinding together two solid analgesics – lidocaine, a free base, and ibuprofen, a free acid – in various mole ratios. They then tested the ability of the liquids to permeate through a model membrane. The aim of the project is to explore the possibility that two strongly interacting APIs can combine synergistically to form a liquid and at the same time be quickly delivered to the blood through the skin.

‘In our experiments, lidocaine and ibuprofen, when combined, did not form a salt but rather a deep eutectic consisting of a tightly hydrogen-bonded complex,’ explains Rogers. ‘It therefore transported across the membrane as a large neutral complex rather than a salt.’

He points out that the term ‘ionic liquid’ probably does not fit in this case. The investigation, however, is a good example of the result of what he calls ‘ionic liquid thinking.’ He strongly believes that ionic liquids are platforms for transformational technologies, not necessarily because of what they are, but because of how they challenge our thinking. ‘Ionic liquids are magic, because they make you think and allow you to dream,’ he says. ‘They permit you to consider doing things others have deemed impossible.’

Michael Freemantle is a science writer based in Basingstoke, UK, and author of An introduction to ionic liquids(Royal Society of Chemistry, 2010)

No comments yet