New method uses 3D printed polymers to make flaw-free ceramic microlattices

A new method for 3D printing ceramic microlattices has been developed by researchers in the US. The lattices have fewer flaws than ceramics manufactured by conventional sintering processes, making them much stronger. The potential applications range from micro-electromechanical systems to jet engines, and potentially even more advanced aerial vehicles such as space shuttles.1

Although they are inherently very strong, ceramic materials are brittle, which means they cannot easily be machined or cast. They are usually sintered by fusing powder grains at very high temperatures. This introduces microscopic flaws that can nucleate cracks when the materials are stressed, often making the actual strength of ceramic objects much lower than the intrinsic strength of the ceramic. To get around this, materials scientist Tobias Schaedler and colleagues at HRL laboratories used ‘preceramic polymers’ that, when heated, pyrolyze into ceramics. The polymers can be deposited as high-purity liquids, producing a more homogenous material with fewer flaws. The team used a mixture of siloxane and silazane, which, when pyrolysed, produces silicon oxycarbide ceramic, using ultraviolet light to crosslink the polymer in the appropriate areas to form the object.

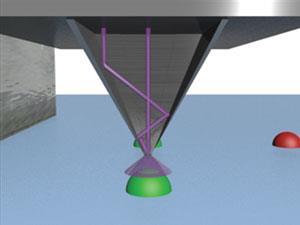

They tried this approach using two 3D printing methods. Stereolithography can form almost any shape by building the object in a series of 2D slices, but this is slow, and the inevitable stepped edges weaken the object. Simpler objects with perfectly smooth edges can be made more rapidly using self-propagating photopolymer waveguide technology, in which the polymer is irradiated through a single mask at the top and as the light passes through the object and polymerises it, the polymer forms a UV waveguide that traps the light, focusing it deeper inside the object. When the unpolymerised resin is washed away, the polymer structure left can be transformed into a ceramic one by firing.

This method cannot produce thick objects as they crack when fired, but it does allow intricately and precisely structured microlattices with densities as low as 0.22gcm-3, which can be rationally designed so that when the material is bent the individual struts stretch or compress, making them much stronger than randomly structured ceramic foams. ‘Any material is stronger in tension and compression than in bending,’ explains Schaedler.

Rishi Raj of the University of Colorado in Boulder, US, whose own group has recently unveiled a method for polymer-derived ceramic manufacture,2 describes the work as ‘quite significant, maybe very significant’, although he says the unsuitability for thick structures precludes many important practical uses of ceramics such as heat shields. Gian Domenico Sorarù of the University of Trento in Italy agrees that the lack of insulation may be problematic. ‘But maybe that is not the main task for these materials,’ he adds. ‘I think applications are in the field of catalyst support, filters and burners.’

References

1 Z C Eckel et al, Science, 2016, 351, 58 (DOI: 10.1126/science.aad2688)

2 L Zoli et al, J. Am. Ceram. Soc., 2015, DOI: 10.1111/jace.13946

No comments yet