A coating for high-performance fibres that changes colour when exposed to damagingly high temperatures – such as from fire or friction – has been developed by researchers from Switzerland. The coated fibres could be used to make self-diagnosing safety ropes for use by firefighters and rock climbers, or suspension ropes for raising heavy loads on construction sites.

When firefighters plunge into burning buildings to rescue people, they often trail behind them a safety rope. With this tether, they can find their way out through the smoke, lead other firefighters to them and – in the worst-case scenario – be pulled out of danger by their colleagues outside. Unfortunately, exposure to high temperatures can weaken the fibres used to make such safety tethers, leaving them at risk of tearing apart while sometimes exhibiting little sign they have been compromised and are in need of replacement.

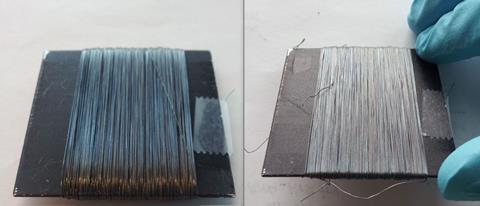

To address this issue, materials scientist Dirk Hegemann of the Swiss Federal Laboratories for Materials Science and Technology and colleagues have created a coating that changes colour from blue to white when heated above a critical temperature. The coating – applied to the surface of the fibre by sputtering – features a reflective silver base layer, an intermediate layer of titanium–nitrogen oxide to keep the silver stable and a 20nm-thick surface layer of amorphous germanium–antimony–tellurium. At high temperatures, this final layer crystallises, resulting in a colour shift brought about by a change in optical interference.

According to the team, the exact point at which the colour change occurs can be tuned within the temperature range of 100–400°C by adjusting the composition of the amorphous layer – allowing it to be adapted to the heat tolerances of the underlying fibre. In the study, the researchers tested the coating on fibres made of PET and Vectran, which are compromised at 150°C and 300°C, respectively.

‘Other fibres in use, such as Kevlar, however, show a more gradual loss of strength. Different coating compositions could thus be used to sense the temperature history,’ Hegemann says.

There is one particular challenge to overcome – that, at present, the coating has a limited shelf-life. ‘Unfortunately, the phase-change materials oxidise over the course of a few months,’ explains Hegemann. After this, the heat-driven crystallisation will not occur and the ropes lose their ability to flag weakness.

Improving this longevity, Hegemann adds, is a topic for future research – alongside application-orientated development of the fibres in collaboration with textile companies.

No comments yet