Combination of intrinsic and extrinsic mechanisms allows silks to retain both toughness and ductility at extremely low temperatures

The yield stress and breaking stress of silk from the wild silkworm Anthreraea pernyi are higher at –196°C than at room temperature, new research shows. The surprising findings made by researchers in China could see the material, or mimics of it, find applications in devices destined for the arctic and outer space.

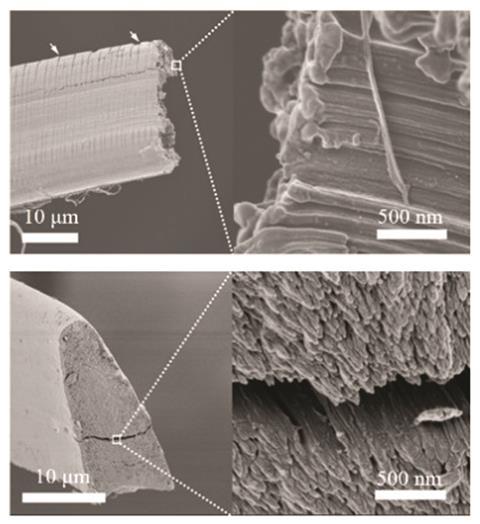

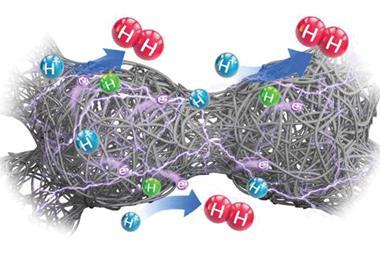

Weak intermolecular forces hold highly aligned nanofibrils in the silk together. These forces allow the fibrils to separate and split when a breakage occurs, deflecting crack paths into the interfibrillar spaces. Parallel cracks form, meaning less energy is carried by the major crack and the fracture develops in a 3D topological manner rather than a simple 1D path or 2D plane. This extrinsic toughening mechanism also allows the fibrils to become blunt when a crack forms, and together these properties prevent catastrophic breakages at cryogenic temperatures.

In addition, the more disordered molecular chains the silks contain, the more ductile they are at very low temperatures – the researchers attribute this to an intrinsic molecular extension mechanism. The low temperature ductility of A. pernyi silk differentiates it from typical synthetic polymeric fibres, which suffer from a strength–ductility trade off at cryogenic temperatures.

References

C Fu et al, Mater. Chem. Front., 2019, DOI: 10.1039/c9qm00282k

No comments yet