Material is thought to be first whose volume increases when stretched or compressed

A material made from a single, entangled coiled wire actually gets bigger – its volume increases – when it’s stretched or compressed, researchers in France have shown. The researchers believe the structure, which can be realised in multiple different materials, may find applications in sensors, actuators, fasteners or smart filters.

When stretched in one direction, most materials become thinner perpendicular to this stretch – but by less than required to compensate for the increase in length – so the overall volume still increases. Conversely, when squeezed, materials usually become thicker, but the volume still decreases. Materials that thicken when stretched are called auxetics, and there are multiple natural and synthetic examples – paper is perhaps the most common. Materials that become sufficiently thinner when stretched that their volume actually decreases, or that thicken enough when squeezed to increase their volume, are called stretch densifying or compressive dilatant materials respectively. Such materials are rare, but reported examples are carbon nanotube yarns and aerogel sheets. Most materials show a similar relationship between stress and volume change, regardless of whether the stress is positive or negative – an auxetic material becomes thinner when squeezed and a stretch densifying material is also compressive dilatant.

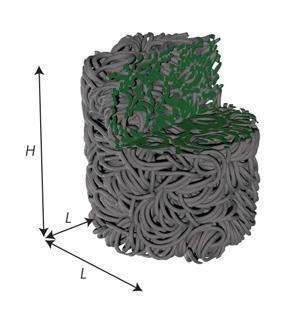

In the new research, David Rodney of the French National Centre for Scientific Research in Lyon and Grenoble and colleagues have developed a material whose volume increases whether it is stretched or squeezed. The structure comprises a single wire twisted into a helix, which is then entangled to form a disordered ball. Finally, this ball is compressed into a cylinder and heated to a temperature that, while high enough to set the shape, is not so high as to cross-link the strands. The researchers produced similar structures from copper, polyamide fishing line and nickel–titanium – a super-elastic shape-memory alloy.

Grace under pressure

When the researchers pressed the materials, they found them to be among the most compressive dilatant materials ever measured. Under tension, however, the materials barely thinned at all – although only materials made from copper were actually auxetic. The volume of the materials therefore increased significantly under either tension or compression. The researchers constructed computer models to explain what was going on. Compressing the structure vertically creates more vertical contacts between the helices: these cannot move towards each other without the helices stretching horizontally. If the structure thins at all on stretching, however, it creates more horizontal contacts that cannot move closer without the helices stretching vertically.

When made from an elastic material such as fishing wire or nickel–titanium, it can retain its remarkable properties over repeated cycles of tension and compression. This is because the structure is made from a single fibre, and so tension can travel all the way through it, allowing the structure to easily reform itself into the lowest energy state. The researchers speculate that the structure may have several potential uses, from stress or compression sensors to fasteners and smart filters that can be actuated by either tension or compression. ‘You can have a relationship between the deformation that you apply and the porosity of the structure,’ says Rodney, ‘And because it’s reversible you can go back and forth.’

‘People are fascinated – I’m fascinated – with materials that play new tricks, and the trick that this material plays is, to the best of my knowledge, unprecedented,’ says materials scientist Ray Baughman of the University of Texas at Dallas. He envisages several directions in which the work could be extended, yielding materials that imbibe and release liquid in response to tension or compression or materials that ‘freeze’ when they reach a particular strain state.

References

D Rodney et al, 2015, Nat. Mater., DOI: 10.1038/nmat4429

No comments yet