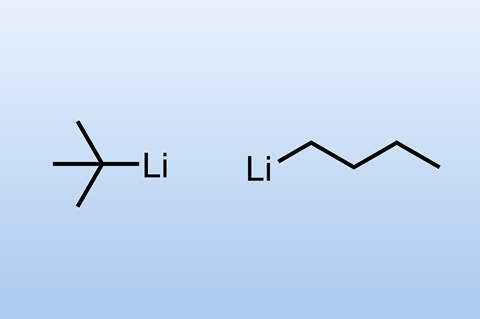

New bench-stable tert- and n-butyllithium formulations in poly(α-olefin) solvents, developed by Merck KGaA, should make organometallic chemistry safer and more accessible. The new reagents don’t ignite or smoke in air, making them easier to handle and less prone to degradation on storage, while maintaining performance across a range of reaction types. ‘We’ve taken one of the bread-and-butter reagents [used in just about every synthetic lab in the world], and made it safer and easier to use,’ says Ben Glasspoole, who works on synthesis reagents and workflows for the Life Science business of Merck.

Butyllithium reagents have wide-ranging applications across industries, often serving as polymerisation initiators or strong bases. But being pyrophoric makes them a significant safety risk. They have been involved in many lab incidents, including the death of research assistant Sheri Sangji in 2009 at the University of California, Los Angeles in the US.

The reagents are generally available as solutions in hydrocarbon solvents, which are themselves flammable and hazardous. Additionally, the sensitivity of t-BuLi and n-BuLi to moisture and air leads to decomposition during storage, requiring chemists to titrate their potency before every use. The need for specialised equipment and training increases costs, slows workflows, and limits the extent to which non-specialist researchers can use these reagents. ‘BuLi reagents – even when used carefully – can smoke, spark or catch fire,’ explains Glasspoole. ‘Our new formulation dials down the pyrophoricity without dialling down performance.’

Previous methods explored for safer organolithium handling include deep eutectic solvents, organogels and oligomeric hydrocarbon solvents. David Bergbreiter’s group at Texas A&M University, US, reported that organolithium reagents stored in poly(α-olefin) (PAO) solvents are more stable and less flammable than conventional solutions. PAOs are synthetic base oils, often used in specialist lubricants. They have branched hydrocarbon structures that help shield BuLi from air or water, but their viscosity makes them difficult to work with.

Merck continued this line of work. ‘We have been interested in this concept for some time, but there’s always a challenge in taking a great idea, and making it work at scale,’ says Glasspoole.

Starting with a commercially available PAO, Merck scientists worked to optimise the viscosity. They then tested its spontaneous combustibility by placing it in the open air at ambient temperature for five minutes, as well as exposing it to filter paper. No charring or ignition occurred. When the reagents were dripped into water, oily droplets formed – but again, no fire. ‘Under similar conditions, traditional reagents would spontaneously ignite or smoke,’ explains Glasspoole. Increased stability also reduces the need for frequent titration, he adds.

To evaluate the chemical reactivity of the new formulations, Merck researchers studied their activity in a range of reactions, including nucleophilic aromatic substitutions, halogen exchanges, C–H lithiations and nucleophilic additions or substitutions. In all cases, reactivity was maintained or improved. Glasspoole suggests that the comparable reactivities mean the new products can be swapped easily into labs’ existing protocols.

Questions remain for David Smith from the University of York, UK, whose group developed gel capsules for organolithium delivery. ‘Merck has provided strong data demonstrating that the pyrophoricity of these organolithiums is reduced by formulation in PAO,’ he says, but wants to know if the new reagents still need to be handled under inert conditions. ‘Some other formulations, such as organogels or deep eutectic solvents, in addition to being non-pyrophoric, also introduce the ability to perform organolithium reactions in the open laboratory … Being able to handle the reagents in air without degradation would be a significant further advantage.’ He also believes that the task of removing PAO from final products may dissuade some researchers.

Both Glasspoole and Smith are hopeful that the new formulations will not only increase safety but also the applications and adoption of organolithium reagents. ‘Safer organolithium formulations may see them more safely used by specialist researchers in synthetic chemistry, but may also see organolithiums more widely used by non-specialist researchers interested in using this type of synthesis for a variety of different applications,’ says Smith. Glasspoole notes that Merck is working to expand its range of similar reagents, and that the new products are ‘far easier to run on liquid handlers and other modern automation systems, lowering barriers to adoption and enabling more reliable, scalable, and sustainable workflows – even for teams without deep chemistry expertise.’

References

T J Malinski and D E Bergbreiter, Tetrahedron Lett., 2018, 59, 3926 (DOI: 10.1016/j.tetlet.2018.09.041)

No comments yet