Cheap-to-make material exceeds US targets for natural gas storage thanks to flexible structure

A new porous polymer can store methane with a capacity 25% greater than the US Department of Energy’s (DOE) targets for natural gas storage materials, and could be produced for as little as $1 (£0.80) per kilogram.

As a fuel source, methane is preferable to petroleum as it is cheaper, burns cleaner and is more evenly distributed around the globe. But due to methane’s low energy density it must be compressed or liquefied in order to become economically viable. Using porous materials to reversibly adsorb methane is a promising way to store and transport the natural gas; however, the highest performing materials to date require complex and expensive syntheses with little in the way of scale-up potential and have fallen short of the targets set by the DOE.

Now, a polymer named COP-150 could change that. The substance contains pores that are shaped by a backbone of three benzene rings which are linked together by flexible ethylene bridges. It’s these bridges, researchers believe, which allow the pores to take up more methane by enabling them to swell and expand under higher pressures – an effect known as breathing.

To measure the storage capacity, a team led by Cafer Yavuz at the Korea Advanced Institute of Science and Technology and Mert Atilhan from Texas A&M University at Qatar subjected a small amount of the polymer to pure methane gas under varying conditions of temperature and pressure. They found that at 273K and 0.01GPa, the material showed a working capacity of 0.625g g-1; 25% higher than the target set by the US department of energy and the highest capacity of any porous material to date.

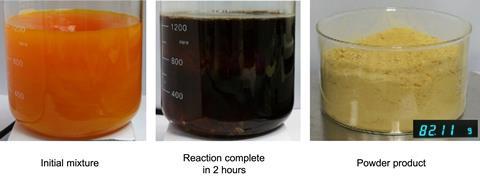

The flexible material can be made at room temperature using cheap starting materials which require no prior purification, leaving the product with a rough cost of $1 per kilogram – a price which could fall further if the process was scaled up.

References

V Rozyyev et al, Nat. Energy, 2019, 4, 604 (DOI: 10.1038/s41560-019-0427-x)

No comments yet