A chemically diverse library of aerogels has been created that remains stable under extreme thermal and mechanical conditions, owing to the materials’ unique dome-shaped structural design. The researchers believe that this will offer flexibility in designing novel aerogel materials for extreme conditions.

Aerogels are an advanced group of materials with a highly porous structure, resulting in extremely low densities and thermal conductivities. This makes these materials attractive for industries such as aerospace and energy.

Typically, the synthesis of aerogels involves the controlled extraction of solvent from a gel – a cross-linked network of polymers within a solution. However, this tends to form aerogels that are brittle and inelastic, due to the inconsistent shape of the pores that form. Chao Gao, leader of the study at Zhejiang University, China, adds that ‘these existing methods [also] have a high cost and use large amounts of energy, meaning that they are not suitable for large-scale industrialisation’. Advanced aerogels employ a geometric structural design – such as a honeycomb – to improve stability, but these are still unstable under extreme thermal and mechanical conditions.

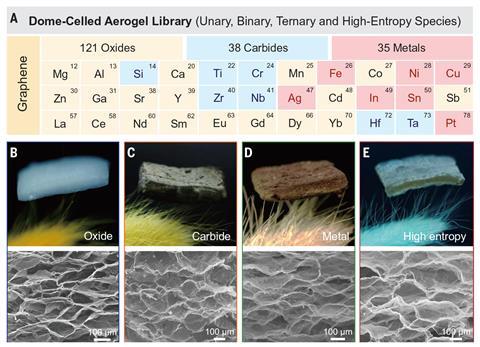

Now, the team has developed a method – known as 2D channel-confined chemistry – to synthesise highly elastic and stable aerogels, featuring regular, dome-shaped pores. The new method involves immersing layers of graphene oxide films into salt solutions, trapping ions within the network. A foaming agent then creates bubbles within the hybrid material, with aerogels subsequently forming after heating.

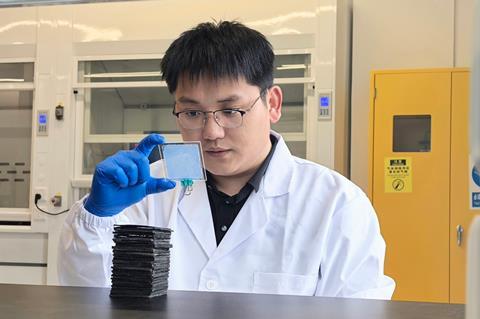

The team could remove or alter the graphene oxide support by heating under different conditions, forming a total of 194 varieties of metallic, oxide and carbide aerogels. All had low densities, but some – known as extra light aerogels – had densities lower than air. Various scales of synthesis – including large-scale plates and continuous rolls – show that these aerogels could eventually meet practical demands from industry.

Under mechanical tests, these aerogels could be compressed repeatedly up to 99% strain over 20,000 cycles, without losing their internal structure. Such aerogels are superelastic. The researchers attribute this impressive stability to the unique dome-shaped pores, with Gao explaining that ‘many buildings – such as cathedrals – often have this [domed] structure as it is quite stable’.

‘For real applications, other types of loading conditions – like stretching, bending or even twisting – could be considered to show [the aerogels] more comprehensive mechanical properties,’ says Xi Shen, a materials expert at Hong Kong Polytechnic University, China.

Some of the synthesised aerogels, notably carbide derivatives, had superelastic and insulating properties that were present through a large temperature range, from 4K up to 2273K. The team were able to shield a rose from a butane flame for 5 minutes with an 8mm thick carbide aerogel without damage.

These materials offer applications in deep space technology where variability in solar energy drastically alters temperatures, but Shen believes that there is still a long way to go before such applications are realised.

References

K Pang et al, Science, 2025, DOI: 10.1126/science.adw5777

No comments yet