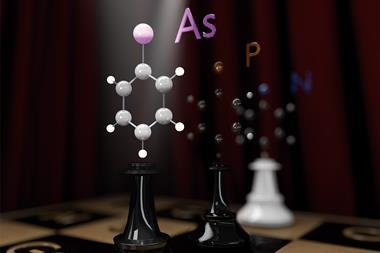

Concentrated arsenic waste generated by groundwater treatment plants can now be easily transformed into metallic arsenic. This new method offers the opportunity to create local, circular production of metallic arsenic – an element now in demand for green-energy technologies – while ensuring clean drinking water.

Nearly all groundwater contaminated with arsenic is due to naturally occurring deposits of arsenic-containing minerals dissolving into it. Chronic exposure to high levels of arsenic in drinking water – defined by the World Health Organization as above 10μg/l – can lead to various health conditions, such as neurodevelopment disorders, cancer and lower intelligence in children. A method to remove arsenic from groundwater that is in use around the world relies on iron oxide nanoparticles to adsorb dissolved arsenic compounds.

‘We know how to remove arsenic from groundwater, but we haven’t really figured out what to do with the waste,’ says Case van Genuchten, at the Geological Survey of Denmark and Greenland in Copenhagen. ‘Arsenic is used in a variety of products, such as batteries, semiconductors and alloys, that are needed to transition from fossil fuels to clean-energy systems,’ says van Genuchten. ‘The societal value of arsenic is changing,’ he adds. In 2022, the US classified metallic arsenic as a critical raw material, followed by the EU a year later. Currently, most of the world’s supply of arsenic comes from China.

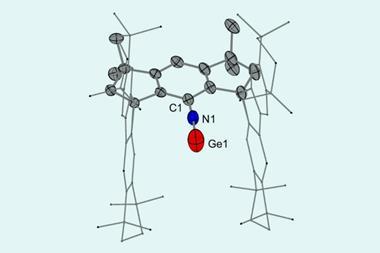

Van Genuchten and Kaifeng Wang have now developed a two-step process that converts the sludge-like waste from groundwater-treatment plants into metallic arsenic nanoparticles. Extraction with sodium hydroxide first de-adsorbs bound arsenic from the iron oxide nanoparticles, creating an arsenic-rich solution of ions of arsenite (As(III)) and arsenate (As(V)). Then, thiourea dioxide, a molecule commonly used as a bleaching agent in the textile industry, reduces these ions. At high pH, the long carbon–sulfur bond in thiourea dioxide breaks, generating urea and the redox-active sulfoxylate. This reductant coverts the arsenic ions into pure nanoparticles of arsenic with a nearly 99% conversion rate. The researchers were able to treat arsenic-laden sludge samples from plants across Denmark, Belgium and the US, highlighting the versatility of the method.

Spectroscopic measurements of the upcycled arsenic nanoparticles revealed an amorphous structure, differing from the crystalline structure of commercially available metallic arsenic. ‘We think that amorphous metallic arsenic has the potential for much better applications in high value or advanced materials,’ says van Genuchten. He explains that the lack of long-range order in the material may make it better suited as a precursor material to certain arsenic-bearing materials, such as the two-dimensional arsenene.

Abul Hussam at George Mason University in the US, who has previously developed filters to remove arsenic and other toxic compounds from groundwater, explains that ‘ultrapure As(0) can be obtained by already established technology [as] As-compound rich minerals are abundant in nature.’ He is sceptical of the process and cautions that arsenic extracted using this new method ‘generates little commercial utility, except for regenerating the iron as metal’.

However, a life cycle assessment conducted by van Genuchten and Wang suggests that recovering arsenic from arsenic-rich sludge could significantly reduce impacts to human and environmental health, compared with mining new material or dumping the waste in landfill.

Areas that have high levels of arsenic contamination in groundwater tend to be in south and south-east Asia, as well as South America, where such regions can face financial barriers to decontaminating groundwater. ‘If we can convert arsenic in the waste into a valuable form, the incentive for treating drinking water in those areas is highest,’ says van Genuchten.

References

K Wang and C M van Genuchten, Sci. Adv., 2025, DOI: 10.1126/sciadv.adz5816

No comments yet