Environmental issues are at the forefront of public consciousness. Challenges such as climate change and pollution are driving governments and companies to commit to reducing their impact on the environment. The chemicals industry in particular must make its products and processes more sustainable. At the macro scale, these challenges require coordination and cooperation globally, such as the UN’s plans for a panel to advise on chemicals, waste and pollution.

At the individual level, lab chemists are equally concerned about the impact of their own day-to-day work. As the Royal Society of Chemistry’s Sustainable Laboratories report shows, chemists want to do more to make their experiments and reactions greener. Concepts such as green chemistry (see box) are familiar to chemists as a way of making their reactions and products more sustainable – yet putting those principles into practice can be challenging. As the RSC report notes, many chemists feel they lack the data they need to make informed decisions.

By doing as much work in silico as possible before going into the lab, it saves time, energy, reagents and solvents

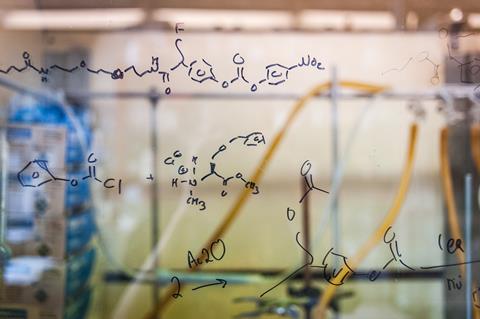

Chemistry information platforms such as Elsevier’s Reaxys can help to fill that gap by providing the knowledge that chemists need to simplify the decision-making process. From a practical point of view, cheminformatics can help chemists to apply three basic principles to make their reactions greener: replace, reduce and predict. Replace boils down to using reagents and solvents with better environmental credentials. Reduce means finding ways to use less energy and materials or to produce less laboratory waste in the creation process. And predict involves using AI and machine learning (ML) techniques to make better products, to design more sustainable routes and processes, and to improve your chances of success before you even pick up a flask.

12 principles of green chemistry

1. Prevention

2. Atom economy

3. Less hazardous chemical syntheses

4. Designing safer chemicals

5. Safer solvents and auxiliaries

6. Design for energy efficiency

7. Use of renewable feedstocks

8. Reduce derivatives

9. Catalysis

10. Design for degradation

11. Real-time analysis for pollution prevention

12. Inherently safer chemistry for accident prevention

Adapted fromGreen Chemistry: Theory and Practice, P T Anastas and J C Warner, Oxford University Press, 1998

Replace

There are several reasons why replacing reagents or reactants will make a reaction greener. Some chemicals are obvious candidates for replacement because they are toxic, carcinogenic or explosive. For example, the dipolar aprotic solvents such as DMSO and DMF that are commonly used by chemists are prime candidates to switch out for a more benign alternative. Instead of these, using a deep eutectic solvent or an ionic liquid could give the same performance with a much lower risk to the chemist and the environment.

Even if a chemical doesn’t present a personal or environmental hazard, it may still be a poor choice if it is derived from fossil fuels. Again, this captures a significant proportion of common organic solvents. Instead of using a petroleum-derived solvent, could you switch to something derived from biomass? Or even use water? With some solvents used in substantial volumes, particularly for purification processes like chromatography, this could be an easy win for upping a reaction’s green credentials.

According to Dr Paloma Engel García, director Reaxys product management, replacing a solvent is one of the easiest green chemistry principles to apply – and one that can have a big impact. Reaxys makes this process even easier because the database extracts all the relevant reaction data – including conditions and yield – from literature papers and patents, and renders them searchable. Rather than the laborious, trial-and-error approach of scouring the literature for papers that might be relevant to your problem and hoping they contain the information you need, advanced searching and filtering in Reaxys lets you search for the data you need directly, reducing the time it takes to identify alternatives. ‘It makes it a lot easier to interrogate that content without having to read all the papers,’ she says. ‘The filters make it easy to narrow down the options.’

As well as choosing a different solvent, avoiding halogenated solvents has obvious environmental and toxicity benefits. A Reaxys query could reveal whether other researchers have previously separated similar compounds to yours using, say, methanol and water instead of a mixture of petroleum ether and DCM.

Using catalytic reactions is another key green chemistry principle, but such reactions can also be inefficient, particularly if they include bulky ligands that are difficult to isolate and recycle. A more atom-efficient catalyst would immediately improve its sustainability. It might also be possible to replace a rare metal catalyst with one that is more abundant or a toxic metal with a less hazardous one. Tin and chromium, for example, are at the heart of many common catalysts, but both are toxic and difficult to purify, generating a lot of waste. Again, chemists can search Reaxys and filter the results based on exactly these parameters; Reaxys extracts the information for you, so you can easily find an alternative catalyst. In addition, it links to the relevant primary literature so chemists can quickly find and evaluate the original research.

Reduce

Another way to render a synthesis more sustainable is to use a shorter route or an alternative process or reaction design. Having fewer steps, for example, means the reaction is likely to produce less waste, require less reagents and consume less energy.

‘There are several aspects,’ Engel García says. ‘One is reaction efficiency. I want a reaction that is higher yielding, with fewer side products. Ideally, it would be very atom efficient, with most (if not all) of the atoms from the starting materials and reagents included in the final product. This reduces waste, too.’

A reaction that takes five minutes will always be more efficient than something that runs overnight

Energy use is another factor. ‘Reactions at room temperature tend to require lower energy input, and therefore are more energy efficient in production,’ she says. ‘While it is obviously important in industrial reactions on a large scale, it makes a difference at a lab scale as well.’

Running a reaction at higher pressure may appear to require more energy, Engel García says, but it actually tends to be more efficient because the reaction happens more quickly. ‘As it’s faster, you ultimately save energy. A reaction that takes five minutes will always be more efficient than something that runs overnight.’

Completely changing the way the reaction is performed is another potential way to reduce energy and reagents. It may be possible to switch from a traditional batch reaction in a stirred flask to a process carried out in some form of flow reactor. And using microwaves or UV might be a better option as an energy source in place of a hotplate.

Reaxys can help here, too, she says. ‘You can choose higher-yielding reactions, setting a filter for, say, reactions with at least a 90% yield,’ she says. ‘Or I could filter for reactions that run at room temperature, or even ones that have been done using flow chemistry with an immobilised catalyst.’ This is another environmental benefit of flow chemistry – with reagents flowing over an immobilised catalyst, it can be cleaned and reused after the reaction, without having to isolate it from a reaction mixture as part of the purification process.

Argentina-based chemist Dr Gustavo Pablo Romanelli, for example, has made extensive use of Reaxys in his work on redesigning synthetic routes to high-value compounds in his Eco-Efficient Organic Synthesis Group. The group uses Reaxys to explore different strategies for reaching a desired compound, and to evaluate them in terms of their sustainability and cost.

Predict

Finally, the wealth of chemical and reaction data that Reaxys contains can also be harnessed to make predictions about reactions before they are even run. Or it can predict the properties of a new molecule before it is made. ‘By doing as much work in silico as possible before going into the lab, it saves time, energy, reagents and solvents,’ Engel García says.

The Predictive Retrosynthesis tool within Reaxys can help redesign a whole route to make it more efficient, Engel García says. It is an AI-based tool developed from a collaboration between Reaxys R&D and the University of Munster, Germany that facilitates prediction of synthesis routes for novel and known target molecules .

‘I didn’t have that when I worked in a lab, and it would have made my life a lot easier!’ she says. ‘It predicts a route to a specific compound, giving reaction conditions and the literature it came from, for each step. So, I can choose shorter routes and then use Reaxys to explore modifications of each individual step to make it greener by replacing reagents or solvents. If you focus on very high yielding reactions they might not even need purification, so the product is simply filtered off .’

Engel García notes that the tool can complete a chemist’s skill set, enhancing and accelerating the design process. ‘Software can help optimise a route, and its suggestions for replacing and reducing can go a long way towards minimising the number of experiments that might need to be done. How can you predict the greenest possible outcome?’

Reaxys includes machine-readable experimental data that allows it to power other AI and ML processes, too. For example, Prof. Alexei Lapkin, a chemical engineer at the University of Cambridge, UK, has been using Reaxys data for several years. Lapkin’s group uses the huge volumes of chemical properties and reaction data contained in Reaxys to build reaction networks in the hunt for more efficient routes to molecules and to find cleaner chemistries through modelling, process improvement and lifecycle optimisation. ‘It’s a completely different way of using the same data to search for improved synthetic accessibility and greener alternatives in silico,’ Engel García says.

Thinking about how to make a synthesis greener should happen right at the start , she believes. ‘You need to choose efficient routes with as few steps as possible, whether it uses reagents and solvents from sustainable sources, and how it will be purified.’ And as a project develops through its inevitable rounds of iteration and refinement, Reaxys makes it easy to keep applying those principles at every stage.

A chemist might instinctively think about using, say, ethanol instead of chloroform, as it’s less toxic, and can be sourced from biomass. In silico tools might suggest alternatives the chemist may not have thought of, but which might work even better. ‘Tools like Reaxys Predictive Retrosynthesis can help do this much faster than manual literature searches,’ Engel García says. ‘They don’t replace chemists, but enhance their work, allowing them to focus on selecting the options that are greener for each step.’

No comments yet