White light emitting diodes are set for a bright future in the household and commercial lighting markets. Ned Stafford investigates

White light emitting diodes are set for a bright future in the household and commercial lighting markets. Ned Stafford investigates

Electronics manufacturers are hailing 2010 as the year that white LED (light emitting diode) lighting will make its mark on the household lighting market. It has been predicted that this year a significant number of consumers will finally start buying LED products to light up their homes.

LED lighting, also called solid state lighting, has a long list of potential benefits over incandescent, fluorescent and halogen lighting, including lasting upwards of 20,000 hours before burning out, extremely low power consumption, no UV radiation, no radiated heat from light, easy dimming, colour possibilities without using filters, focusing capability, shock resistance, no buzzing or hum, and easy digital control. But high prices and technology problems have so far prohibited their mass uptake by homeowners.

The LED white lighting market is however already booming in the commercial sector - in offices, hotels, factories and other businesses - as firms, which have more lights glowing for more hours per day than homes, can recoup LED investment within a few years in reduced energy and replacement costs. Companies also benefit from a combination of subsidies and tax breaks for using these low energy products.

Now, manufacturers believe that semiconductor and other technologies behind LEDs are finally capable of producing pleasant white lighting at prices, which although not yet cheap are low enough to trigger increased household sales. And as a result, this year lighting retailers are expanding their offerings of LED lighting products for the home.

The market will also get the added boost of government mandated gradual phase outs of electricity-guzzling incandescent bulbs, already underway in Australia and parts of Europe (including the UK), and due to start in 2012 in the US.

Aiming for world domination

George Craford, solid state lighting fellow at the LED lighting company Philips Lumileds Lighting in San Jose, California (part of the global electronic giant Philips), sees the expected increase in LED sales in 2010 as the first small step of a massive reorganisation of the global lighting market in coming years. ’I don’t think there is any question of LED completely taking over lighting. It is a virtual certainty,’ he adds.

Craford admits that as little as three years ago one could justifiably question whether LED lighting for home and office was good enough to compete in the open marketplace. But no longer. ’LED performance has continued to go up and up,’ he says.

Wang Nang Wang, leader of the wide band gap semiconductors group at the University of Bath, UK, agrees. ’LED performance has now reached the fluorescent tube level,’ he says. ’There is growing demand for LED lighting and that demand is not hype. Light has become part of the digital revolution.’

The market is nonetheless still in an infant stage. Shuji Nakamura at the University of California at Santa Barbara, US - who in 1992 developed the elusive blue LED, the final piece in the puzzle needed to produce white LED light says that he expects LEDs to become the dominant form of white lighting, but not until product prices drop sharply.

Nadarajah Narendran, director of research at the lighting research centre at Rensselaer Polytechnic Institute, Troy, New York, agrees that LED lighting has ’turned the corner’ and will start to post significant gains in market share this year. However, he adds: ’is this the year everybody runs out and buys LED lights? Probably not.’ Nonetheless, he sees LED lighting growing to 25-30 per cent of the total lighting market within five years, with variations in various market subsectors, and reaching 50 per cent ’probably within the next 10 years’.

Global LED growth at Philips is already growing at a spectacular rate, according to Simon Poulter, a company spokesperson based in Eindhoven, the Netherlands. Total sales of LED products grew 42 per cent in the final quarter of 2009 compared to the final quarter of 2008, he said. He added that during the final quarter of 2009, LED sales rose above 10 per cent of Philips’s total global lighting product sales for the first time.

Getting technical

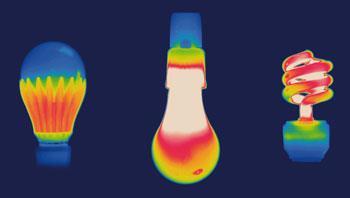

The technology behind LED lighting has more in common with the chips in your computer than with incandescent bulbs or fluorescent tubes. With incandescent bulbs, electric current resistance causes tungsten filaments to heat up and glow, with 90 per cent of the energy wasted as heat. In fluorescent lamps, electricity is used to excite mercury vapour, producing shortwave UV light that is converted to visible light when it strikes the tube’s phosphor coating, with about 80 per cent of energy wasted as heat.

In LED lighting, the diode contains a tiny chip, usually about 1mm2 and grown from many layers of semiconducting material. LED lighting packages can contain just one chip or multiple chips, which are mounted on heat-conducting material called a heat sink and usually enclosed in a lens. Electrons flow within the diode from the p-side (anode) to the n-side (cathode), but not in the reverse direction. As the electrons transit the p-n junction they fall into a lower energy level, which causes them to give off a photon of light. A small amount of heat is released back into the heat sink, leaving LEDs generally cool to touch.

LED devices, used separately or in arrays, are mounted on circuit boards, which can be programmed to include lighting controls such as dimming, light sensing and pre-set timing. The circuit board is mounted on another heat sink to manage the heat from all the LEDs in the array. The final system is then generally encased in ’traditional’ light bulbs or tubes, called retrofits, designed to be screwed into existing incandescent, halogen or fluorescent fixtures.

Diodes can be made from different materials and substrates, each of which has an individual band gap that determines the light emitting wavelength, with various semiconductor compounds therefore producing unique colours. White light is created by combining light from different coloured LEDs within an LED device, or by coating a blue LED lens with phosphor.

The chip technology behind LED lighting means that the global lighting market now dominated by Philips, General Electric and Osram Sylvania is going to be wide open to competition. Firms with expertise in semiconductors, such as Samsung and Panasonic, are already marketing or planning to market LED lighting products.

An even brighter future

Although LED consumer lighting products are being rolled onto the market this year, LED research is far from over. LED lighting still has disadvantages that need to be rectified in the laboratory before the digital revolution can conquer the global lighting market, according to Wang. ’The product is clearly going to get better and cheaper,’ Craford concedes.

The cost of producing LEDs has plunged since the 1970s while quality has soared, but product prices still remain too high to trigger the sort of mass buying needed for a true digital lighting revolution. Last year LED 7.5 watt bulbs designed to replace 60 watt incandescents were priced in the US at over $100 (?66). Prices have plummeted to below $50, but that is still too expensive for most consumers.

Narendran says the key to cutting manufacturing costs is to increase lumen (the standard unit used to measure the power of light perceived by the human eye) output per watt of electricity used. The upper range of LED lighting systems on the market is around 60-70 lumens per watt, about the same for fluorescent tubes but much higher than the 15 lumens for incandescent bulbs. ’The goal is two hundred lumens per watt and we should reach that in three to four years in the commercial market,’ Narendran predicts. And what happens this target is reached? ’Two hundred is the goal, but it is not the maximum that could be achieved,’ he explains. ’Science will work until the last day. If you can get a few more photons, then scientists will be working.’

Nakamura also agrees that price per lumen is a key point. The cost of manufacturing LEDs has halved in the past year alone, falling from$80 per 1000 lumens last year to around $40 per 1000. Current prices for incandescent bulbs are significantly lower at around $1 per 1000 lumens. LED prices will need to plunge to $1 to $2 per 1000 lumens in order for LED to compete in the open market, he says, adding, ’we need some breakthroughs to reduce the cost of LED bulb lamps for the application of general lighting.’

History of LEDs

The 9 February 1907 issue of Electrical World contains the first public reference to electroluminescence from an LED. In a letter to the journal, Henry Joseph Round, a British engineer for the Marconi Company, said: ’during an investigation of the unsymmetrical passage of current through a contact of carborundum and other substances a curious phenomenon was noted. On applying a potential of 10 volts between two points on a crystal of carborundum, the crystal gave out a yellowish light.’

Between 1927 and 1941, Russian radio expert and inventor Oleg Vladimirovich Losev published multiple LED papers in Russian, German and British journals, although his work did not receive widespread acclaim until decades later.

While Round and Losev had used silicon carbide in their early LED work, scientists in the 1950s began experimenting with electrical currents on gallium arsenide, which emits infrared radiation. By the early 1960s, scientists at companies Texas Instruments, General Electric and RCA Laboratories were working towards development of the first ’modern’ LEDs. In 1962, Nick Holonyak Jr invented the first practical visible-spectrum LED, which was red, at the top of the colour spectrum.

By the late 1970s, orange, yellow and green LEDs had followed. But without blue, the shortest wavelength of visible light, white LED lighting was not possible - and this colour proved difficult to make. In the early 1990s, Shuji Nakamura finally cracked the puzzle, producing a blue LED could either be combined with red and green (or shined on a phosphor coated lens) to produce white light.

A word of caution

Narendran says LED lighting research is focused on improving four areas: materials, electrical, optical, and thermal. ’All of these things lead to higher light output and better efficacy,’ he explains.

But fitting all these four pieces together to produce high quality LED products is not easy and consumers should be careful before buying, Narendran cautions. Like any other market, not all LED manufacturers are producing quality products. ’Some products are good, some are bad and some are really bad,’ he says, but notes that LED products aimed for the commercial market are generally of a higher calibre than those designed for residential use.

Poor quality products could have variations in colour or undergo colour shifts within a short period of time, experience a sudden drop in light output, or fail if thermal issues are not properly addressed in LED design or integration, he says. Wang agrees, saying that, ’thermal management is a key issue for high power LED chips because the chip is so small and heat so localised.’

The focus at Philips, according to Craford, continues to be on ’producing higher efficacies at high current densities and producing better phosphors to improve light output and quality of light’.

Looking into a crystal ball

While most current LED white lights are designed for retrofitting into existing fixtures, the solid state technology behind LED lighting does give manufacturers freedom to tinker with new shapes and designs in the future.

Lighting as we know it will undergo a major transformation in coming years, says Til Moor, a spokesperson for Osram Sylvania. ’Light will also be used as a design element, to lend [rooms] a different shape, perception or atmosphere,’ he says, adding that LED lighting in a room could be programmed to change colours, like the sun, for example a bluish tone at beginning of day gradually shifting to warmer, yellow tone toward late afternoon.

Narendran compares LED technology to the ever improving performance of computers, saying: ’it is like the way you keep updating computers.’ He takes the computer analogy one step further when explaining the logic of buying LED lighting products today, when experts agree that the technology is in its infancy. ’When did you buy your first computer?’ Narendra says, ’10 years ago? 20 years ago? You could have waited until today for better computers and lower prices.’

While some buyers of LED lights in the past year or two have no doubt been technophiles wanting to check out the new technology, well-known businesses, city governments and even monarchs are already converting to LEDs. Both Walmart and Starbucks have installed LED bulbs in some US stores to cut energy consumption; Amsterdam in the Netherlands uses LEDs to light its streets, and some cities in the US (including Los Angeles) are planning to retrofit their street lighting with LEDs. Even the English Queen has joined in, using LEDs to light up Buckingham Palace in London.

Ned Stafford is a freelance science writer based in Hamburg, Germany

No comments yet