Catalytic resonance theory poised to tackle industry’s selectivity issues

Breaking the Sabatier limit central to unconventional approach for optimising reactions

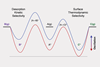

Advances in a concept called catalytic resonance theory could help chemists create heterogeneous catalysts that can overcome selectivity issues plaguing chemical manufacturing. Researchers in the US had previously used computational models to show that oscillating waves matched to the frequency of chemical transformations, such as adsorption and desorption, should be able to accelerate a reaction beyond what was previously possible. Now, they’ve theorised that the same concept can be used to selectively generate a particular product.