Polymers designed to degrade upon exposure to gamma rays

Phenyl imine conjugated N–N bonds mean materials are ready for recycling

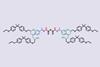

Scientists in China have designed and developed a series of epoxy thermoset resins containing gamma ray-responsive bonds. The new polymers, which have mechanical and thermal properties comparable with those of commodity epoxy resins, degrade in a controlled manner on exposure to gamma irradiation.