Meera Senthilingam

This week, the rare, lustrous element that we have to thank for our flat screen TVs and computer monitors. To tell us more about the chemistry of indium here's Claire Carmalt.

Claire Carmalt

Until 1924 a gram or so constituted the world's supply of indium in its isolated form. Today around 480 tonnes are produced annually from mining and a further 650 tonnes annually from recycling. So why all the need for indium and what are the unique properties of it that makes it a much sought after element?

Indium is relatively rare with its abundance in the Earth's crust estimated to be around 0.1 parts per million. Hence it is slightly more abundant than silver or mercury. Indium is generally found in ores of zinc and is produced mainly from residues generated during zinc ore processing. Indium is a moderately toxic metal by inhalation and mildly toxic by ingestion. However, the exact nature of its human toxicity is not clearly understood.

Indium is a soft, malleable metal with a brilliant lustre. The name indium originates from the indigo blue it shows in a spectroscope. Indium has a low melting point for metals and above its melting point it ignites burning with a violet flame. Bizarrely, the pure metal of indium is described as giving a high-pitched "cry" when bent. This is similar to the sound made by tin or the 'tin cry", however, neither of them is really much like a cry!

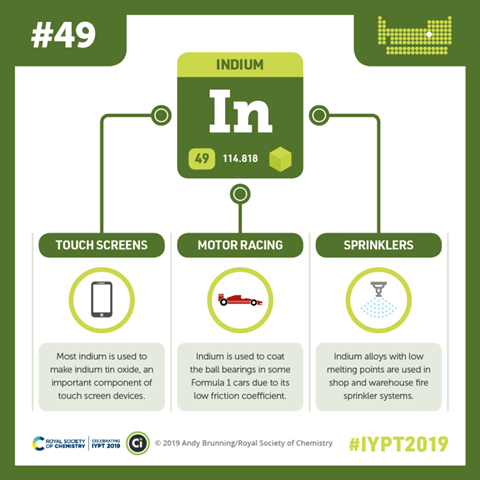

It has the unusual property of remaining soft and workable at very low temperatures. This property allows it to be used in special equipment needed for temperatures near absolute zero. It is an excellent choice for cryogenic pumps, high vacuum systems and other unique joining and sealing applications. Indium lends itself to this application due to its ability to conform to many irregular surfaces and its characteristic "stickiness". Indeed, when pure, it sticks very tightly to itself or to other metals. This property makes it useful as a solder – it reduces the melting point of some solders, strengthens others, and prevents some solders from breaking down too easily. For example, when used as a washer between a silicon diode or other temperature sensors and refrigerator cold stages, indium foil increases the thermal contact area and prevents the sensor from detaching due to vibration. Other uses of indium are in the manufacture of batteries and electronic devices, and in research.

Another important use of indium is in making alloys – used in electronic devices and dental materials. Indium has been called a "metal vitamin" in alloys, which means that very small amounts of indium can make big changes in an alloy. For instance, the addition of small amounts of indium to gold and platinum alloys makes them much harder. Some aircraft parts are made of alloys that contain indium and it prevents them from reacting with oxygen in the air or wearing out.

Indium metal dissolves in acids, but does not react with oxygen at room temperature. However, at higher temperatures, it combines with oxygen to form indium oxide. It is in this form that indium finds application as a transparent conductive oxide. As the name indicates these materials, when applied as a thin coating onto glass or plastic films, are both transparent to visible light as well as electrically conductive. It is actually Indium Tin Oxide or "ITO" which is used and this is one of the most important applications of indium.

About 45% of all indium is used to make ITO and this finds application in solar cells and flat panel displays (LCDs - liquid crystal displays). For both of these applications the ITO is used to establish an electric current over the device and to pass light through it. When architectural or photovoltaic glass is coated with ITO it keeps the harmful infrared rays of the sun from passing through. If coated onto aircraft or automotive windshields, it allows the glass to be electrically deiced or demisted as well as reducing the air conditioning requirement by reducing heat gain. Other compounds of indium used in solar cells include indium gallium arsenide and copper indium gallium selenide. Many scientists think that solar cells may replace natural gas, coal and oil for many applications in the future. However, the availability of indium has been questioned since the demand has risen rapidly in recent years with the popularity of LCD televisions and computer monitors. On the free indium market, this has lead to considerable price increases and the unavailability of sizeable quantities of indium. Currently, increased recycling and manufacturing efficiency maintain a good balance between demand and supply.

Meera Senthilingam

So, an element with a multitude of uses, varying from solar cells and windscreen demisters to LCD screens, batteries and even dental materials. No wonder we need to recycle it to meet the element's demand. That was University College London's Claire Carmalt with the chemistry and uses of indium. Now next week an element that changed the rules of nature.

Eric Scerri

Until the early 1960s it was believed that three bonds between any two atoms was as high as Nature could go, as in the case of the nitrogen-nitrogen triple bond for example. But in 1964 Albert Cotton and co-workers in the USA discovered the existence of a metal-metal quadruple bond. Yes you guessed it, it as rhenium!

Meera Senthilingam

Join UCLA's Eric Scerri to find out what other surprises rhenium has in store in next weeks Chemistry in its Element. Until then I'm Meera Senthilingam from the Naked Scientists.com and thank for listening.

No comments yet