Chemists develop a new method to produce supported black phosphorus with applications in catalysis

Crystals of black phosphorus – a very tricky allotrope of phosphorus to make – can now be grown cheaply and simply. Moreover, black phosphorus prepared using this method can catalyse water splitting, something unprecedented for this material.

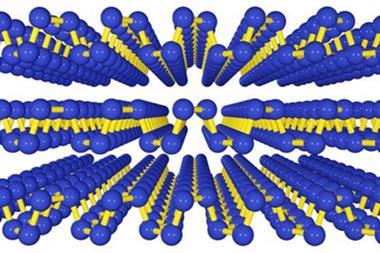

Despite its excellent stability, black phosphorus is the most difficult phosphorus allotrope to prepare. Its electronic properties, and also the ability to use it to make two-dimensional phosphorene, means chemists are very interested in it, however. Current strategies to prepare black phosphorus usually require extreme pressures and temperatures, making it very costly to make. A team led by Shuangyin Wang at Hunan University in China has now developed a new reproducible method that only requires a furnace to make black phosphorus.

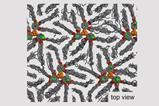

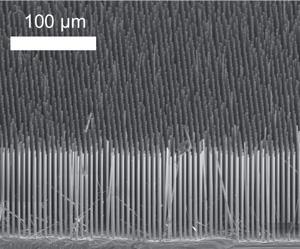

Wang and co-workers use thermal-vaporisation transformation: they first vaporise another allotrope of phosphorus, red phosphorus, and then heat it to 650°C to transform it to the black allotrope, which deposits on a thin, cold titanium foil. ‘This new method offers a facile approach to supported black phosphorus films,’ says Wang. ‘And we can also deposit it on other substrates like carbon nanotubes, carbon fibre, or a silicon wafer.’

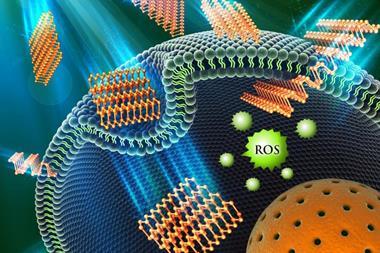

Moreover, Wang’s team observed that black phosphorus films have very good electrocatalytic properties. Like other semiconducting materials such as metal oxides, nitrides and sulfides, this form of black phosphorus can be used to catalyse the oxygen evolution reaction (the anodic reaction in water splitting). When they use black phosphorus grown on carbon nanotubes they achieve Faradaic efficiencies of up to 98%, which is comparable to commercially available ruthenium catalysts. ‘The process for obtaining black phosphorus on nanotubes is ready for scale-up; we could easily prepare big quantities and sell this material in the future,’ says Wang.

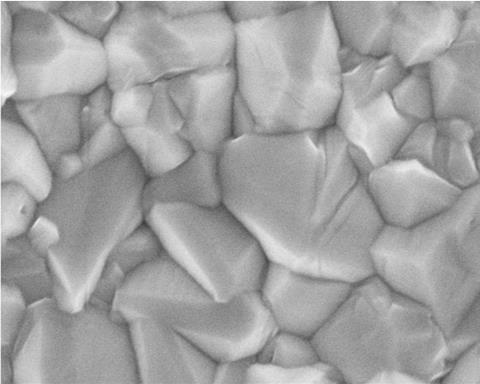

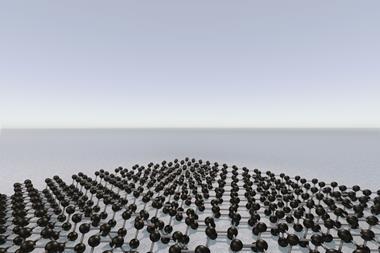

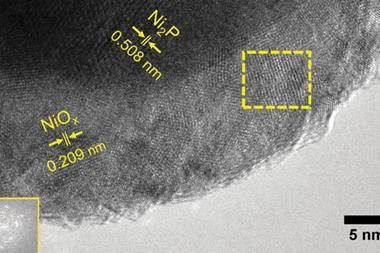

However, this new material may not be ideal for the production of phosphorene. Tom Nilges, an innovative materials researcher at the Technical University of Munich in Germany, says ‘to get phosphorene one needs a crystalline material with the right orientation’. Nilges observes that the microscopy images show the ‘crystals are grown in every direction, which makes mechanical delamination difficult’. Wang agrees, and highlights the importance of their research: ‘We have a new method to produce black phosphorus and we demonstrate a novel application.’

References

Q Jiang et al, Angew. Chem., Int. Ed., 2016, DOI: 10.1002/anie.201607393

No comments yet