As more people want ingredients ‘free-from’ existing staples, Victoria Atkinson looks at the science behind substitutes for gluten, eggs and gelatine

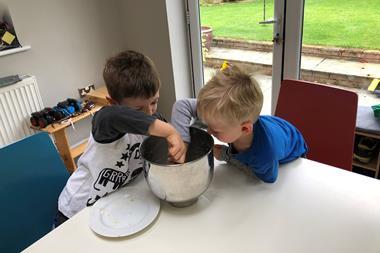

Baked goods have been a firm favourite for thousands of years, and thanks to TV programmes such as The Great British Bake Off (and more recently Covid lockdowns), this old hobby has experienced a renewed surge in popularity over the last 20 years. But as more and more people switch to allergen-free or plant-based diets, these ancient cooking practices need an urgent update.

Whether baking a traditional recipe, or preparing a ‘free-from’ analogue, understanding the underlying chemistry at work in the mixing bowl is vital to obtain the perfect finished product. ‘Ingredients play different roles depending on what you’re making so it’s important to take the time to look at them in terms of what properties they bring to the bake and what functions they carry out,’ explains Katarina Cermelj, a free-from food blogger and award-winning cookbook author with a PhD in inorganic chemistry, based in Silverstone, UK. ‘As soon as you want to change something about a recipe, you need to understand what’s going on in the mixture: how the ingredient ratios, their pHs, the moisture levels in the dough or batter, even the way you combine the ingredients all affect the texture of the final bake.’

But while old favourites such as cakes, breads, and meringues are quick and easy to whip up with standard ingredients, making the switch to gluten-free or vegan recipes is a much greater challenge. To work out how to best replicate the crucial properties of conventional ingredients such as flour, eggs, and gelatine, we must first understand the chemistry of each.

Supporting the structure

Flour is the cornerstone of almost every type of bake. ‘It’s basically a dry ingredient which gives structure to bakes because it contains gluten,’ says Cermelj. ‘This gives the mixture some flexibility and elasticity which is important for bread and pastry but also helps bind softer bakes like cakes and biscuits so they don’t crumble apart when handled.’

Traditional baked goods typically use wheat flour which is available in a myriad of formulations, including plain, self-raising and bread, depending on the intended use. While the major component is starch, crucially each wheat flour formulation contains a small percentage of two proteins: glutenins and gliadins, the precursors to gluten.

‘Glutenin is responsible for the elasticity of gluten. It contains repeated sequences of glutamine–proline–glycine–glutamine amino acids which generate β-turns to create a spring-like structure,’ explains Courtney Simons, a food scientist at Wright State University in Ohio, US. ‘Gliadins allow for extensibility and flow in the dough, essentially acting like a lubricant or solvent between the chains of glutenin.’

As the flour is handled in the presence of water, glutenin and gliadin begin to combine: cysteine residues on each protein form interchain disulfide bonds while glutamine and other hydroxyl-bearing amino acids form hydrogen bonds, creating a single larger protein known as gluten. This resulting macro protein is both strong and elastic, crucially allowing the dough to expand as gas is released during baking. The unique viscoelastic properties of the gluten network enable it to trap these gas bubbles, giving cakes and breads their signature spongy texture.

Gluten is nature’s gift and there’s no real substitute for it

But exactly how the mixture is handled determines the extent of this vital gluten formation. ‘You’re mechanically inducing bond formation so the more you knead the dough, the more gluten develops,’ says Simons. ‘This is important for bread which will collapse during baking without enough gluten, but products like cakes and cookies don’t need as much and may become tough if overhandled.’

Despite its important structural role, however, it’s estimated that the gluten protein is problematic for 2–3% of the global population, with around half of those suffering from coeliac disease. Many types of gluten-free flour are already available on the British market including almond, rice, and oat, but Cermelj warns it’s not as simple as making a direct substitution. ‘For gluten-free baking to be successful, you usually need a mix of different flours in the correct ratio so you get the right flour profile in terms of starch content. You also need to somehow replace gluten’s function as a binder,’ she says.

By gum

Typically, gluten-free bakers employ hydrocolloid gums such as xanthan to produce this elastic binding property. Xanthan gum is a branched polysaccharide produced by the Xanthomonas campestris bacterium. This hydrophilic polymer dissolves easily in water to form a gel-like structure, able to increase the viscosity of liquid mixtures and give much-needed elasticity to firmer doughs.

But it’s also important to consider the other impacts of this hydrophilicity. ‘On average, gluten-free flours tend to absorb a bit more moisture than regular wheat flour so a direct swap might result in a dry bake,’ warns Cermelj. ‘You need to compensate for this either by adding an extra egg or a bit more milk (for moisture) or using slightly less flour in your recipe.’

While this substitution works well for softer bakes such as cakes and biscuits, gluten’s more fundamental role in breads is harder to replicate. ‘Gluten is nature’s gift and there’s no real substitute for it, especially in bread,’ says Simons. ‘Gums may help to strengthen the cell walls of gas bubbles in dough but there is no substitute for the taste and real texture of gluten.’ For gluten-free bread Cermelj recommends psyllium husk, a hemicellulose derived from the Plantago ovata plant, explaining that this gum gives a truer-to-original texture than other substitutes currently on the market.

But for Natalie Feller, a PhD student in Mario Jekle’s group at the University of Hohenheim in Germany, a similar texture in gluten-free bread just isn’t good enough. ‘Rather than mimicking the viscoelastic properties of gluten to form a foam-supporting network, we’re using plant-based surfactants to improve the stability of the interface between gas bubbles and dough,’ she explains. ‘I’m using surface-active proteins and saponins from quinoa, daisy, tribulus, beetroot and canola which should be able to form a durable film that effectively traps the gas bubbles and withstands the stresses of dough expansion.’

Feller first extracts samples from each plant source, analysing and characterising the individual compounds before testing their foaming properties in aqueous solution. Promising samples are then trialled in a standard dough recipe and the team probes the structure and stability of the resulting foam during proving and baking. Too large, too small or too flimsy gas bubbles can easily coalesce or collapse as the dough expands, creating a dense and heavy bread after baking. Finding the right surface-active properties is therefore crucial to obtain the correct bread texture.

‘The selected proteins must have both hydrophobic and hydrophilic regions. When they attach to the surface between the solid and the gas, they form a stabilising dielectric layer,’ says Feller. ‘For saponins, many factors affect how these bubbles are stabilised, including the branching, composition, and length of the sugar residues within it, and the orientation of these molecules on the dough surface.’

Ultimately, Jekle’s team hopes to gain a deeper understanding of the different mechanisms of action at this surface interface and how this correlates with real-term improvements in gluten-free bread texture and structure.

An all-encompassing ingredient

Eggs are perhaps the most versatile ingredient in baking and can play a huge number of different roles depending on the recipe. ‘It’s easiest to think about egg whites and egg yolks separately as they’re actually very different ingredients,’ says Cermelj. ‘Egg whites are elastic and structural and they have this amazing ability to form a very stable foam. On the other hand, egg yolks give a richness and creaminess to the overall flavour and have important emulsifying, thickening and binding properties.’

Chemically, the humble egg is incredibly complex with each of these different functions exploiting a different component of this seemingly simple ingredient. The whites are rich in water and contain the bulk of the protein, a mixture of albumins and globulins, and it’s this combination of moisture and soluble proteins which accounts for the impressive foaming effect. ‘When you whisk up the white, you are entrapping air between the water and protein to form a foam,’ explains Fatma Boukid, a food scientist and senior project manager at ClonBio Group Limited in Hungary.

The mechanical agitation slowly causes the globular proteins to stretch and unravel, allowing the individual strands to reorganise: the hydrophilic ends align with the egg white solution, and the hydrophobic ends are attracted to the air pockets, creating a stable foam. In meringues, added sugar helps balance the moisture content to stabilise the whipped foam further but the important chemical change occurs in the oven. Prolonged heating coagulates the albumin proteins, driving the formation of new hydrogen and disulfide bonds between chains, which cause the foamy mixture to thicken and set into a hard meringue.

In cakes, this same gas-trapping property produces an important leavening effect. Air trapped within the eggs’ protein network expands in the heat of the oven and, as the albumins coagulate, this open voluminous structure solidifies to create a soft and airy texture in the finished cake. ‘But often the egg is playing more than one role,’ says Boukid. ‘In a sponge there is a big moisture contribution from the egg which prevents the cake from becoming dry and crumbly. And there are the emulsification and flavour properties from the yolk.’

Egg yolks principally contain fat and cholesterol which impart a rich and creamy flavour to the bake. But crucially, they also contain lecithin, an amphiphilic phospholipid which gives the yolk its emulsifying and binding properties. The surfactant-like structure, with hydrophilic and hydrophobic ends, helps create a smooth and homogeneous batter by enabling the butter and any other fats to mix with the aqueous ingredients in the mixture.

With all this complexity, there is no single substitute able to replace all the functions of a chicken egg. ‘You need to understand which roles the egg plays in that particular recipe and try to replace it with one or more ingredients that can replicate those roles,’ says Boukid. ‘It often has to be a reformulation of the recipe, not just a substitution.’

The best-known egg alternative is aquafaba (chickpea water), a common vegan substitute for the foamed egg white in meringues. This dilute solution of proteins and polysaccharides is extracted by boiling legumes in water and contains water-soluble albumins and globulins, similar to the proteins in egg white. These, in addition to emulsifying saponins, give aquafaba a comparable foaming ability and, as in a typical egg meringue, mechanical beating creates a stable foam which is coagulated in the oven to make a stiff set dessert.

You need to understand which role the egg plays in that particular recipe

For the binding and emulsifying properties, bakers turn to the same hydrocolloid binders used in gluten-free flour. Xanthan, flax, and chia gums are all common replacements, but Cermelj warns it’s important to stick to the recipe with egg-free bakes. ‘These gums can replace the binding power but you have to get the balance right to avoid an overly gummy and dense texture,’ she says. ‘Additional raising agents can mimic eggs’ leavening effect but too much can give a metallic flavour. If you don’t have the inclination to experiment, I’d recommend finding a reliable egg-free recipe and following it exactly as they take a lot of time to optimise!’

A similar role-by-role approach is required when developing egg-free alternatives in the lab. David McClements and his colleagues at the University of Massachusetts in the US have chosen to focus on the gelling property of egg white and are exploring whether RuBisCo, a globular protein obtained from the leaves of green plants, could be a suitable alternative to chicken eggs both as a structural ingredient in bakes such as cakes and quiches, as well as a standalone alternative to cooked egg white.

The team used commercial samples of RuBisCo protein isolate obtained from duckweed and prepared solutions at a variety of concentrations and pHs to probe its gel-forming behaviour. As with chicken egg whites, prolonged heating causes the globular proteins in RuBisCo to denature and form a new network of intermolecular bonds, creating a coagulated gel-like structure. The group reported the texture profile, viscosity, gelation behaviour, and rheology possessed promising similarities with original egg whites and the team are now working to make the RuBisCo gels less brittle and to remove the traces of brown colour caused by polyphenol impurities.

A melt-in-the-mouth texture

Gelatine is a slightly more specialist baking ingredient but nonetheless essential in the set components of a huge number of popular desserts such as jellies, custards and mousses. A polypeptide mixture extracted from animal collagen, gelatine’s setting property comes from these molecules’ ability to reversibly form and break hydrogen bonds between strands, enabling them to switch between gel and liquid forms depending on external conditions such as temperature, pH and hydration. ‘You can repeat this process many times which makes gelatin very convenient to set food or improve the texture in different products,’ explains Lingyun Chen, a food scientist at the University of Alberta in Canada.

Gelatine typically comes in either powdered or sheet form but bakers must first activate this dried ingredient through a process called blooming. The raw preparation is soaked in cold water to hydrate the amino acid residues, readying them to form hydrogen bonds. This soaked gelatine is then dissolved in hot (but importantly not boiling) water to distribute the polypeptide chains throughout the solution without denaturing them, before mixing into the other wet ingredients. As the solution cools, new hydrogen bonds form between the protein strands, thickening the mixture into a set dessert. ‘Gelatine is easy to handle because of this excellent thermoreversibility,’ says Chen. ‘It also has the unique property of melting at body temperature which gives it a pleasant melt-in-the-mouth sensation like chocolate.’

The current vegan substitutes are a little less user friendly. Agar agar is a common alternative made from a mixture of polysaccharides derived from algae. Like gelatine’s protein strands, agar’s agarose polysaccharide chains reversibly form and break hydrogen bonds to thicken mixtures but it produces a firmer and more brittle gel texture, particularly problematic for soft desserts such as creams and mousses. The gel melts 85°C, meaning it remains solid in the mouth and, once melted, the solution also solidifies at temperatures below 40°C which can make it challenging to distribute evenly through dessert mixtures.

Chen and her team have recently developed a more practical substitute, using a plant-based protein derived from peas. ‘Many globulin proteins from plant and animal sources can form gels. Globulin proteins have hydrophilic amino acids on the outside and hydrophobic amino acids inside. When you heat them, the structure unfolds and exposes those hydrophobic residues which can then interact through different covalent and non-covalent interactions to form a gel,’ she explains. ‘The major protein in peas is also a globulin but, if the unfolded protein forms covalent interactions such as disulfide bonds, they are less reversible so we have to manipulate the local environment to make sure hydrogen bonding is the major interaction.’

Chen’s team extracted the pea protein isolate from plant samples to create a powder similar to conventional bakers’ gelatine. After dissolving, the team used fruit juice to adjust the pH of the solution and control the bonding interactions. A mildly acidic pH supported the gelling behaviour and the team was able to produce a vegan jelly comparable to existing animal-based desserts. ‘Going forwards, I’d like to try more food formulations like cake toppings and yoghurts to explore the full potential of our pea protein,’ Chen says. ‘We’re also looking at scaling up this technology so it can be manufactured at an industrial level.’

There are so many reasons why someone might choose to avoid certain ingredients – food intolerances, religious beliefs, sustainability concerns – so creating practical and effective baking substitutes is now more relevant than ever. ‘It’s so important that we talk not just about recipes and ingredients, but also why things work so people can make these recipes their own,’ says Cermelj. ‘I don’t think anyone should be deprived of delicious food just because they can’t or won’t eat a certain ingredient!’

Victoria Atkinson is a science writer based in Pocklington, UK

No comments yet