Chemical-looping combustion methods aim to help power plants produce separate carbon dioxide to aid its sequestration. James Mitchell Crow keeps us in the loop

In today’s carbon-choked times, it seems unlikely that anyone would deliberately burn fossil fuels just to generate carbon dioxide. But 60 years ago, that’s just what two Americans were trying to do. In 1954, Massachusetts Institute of Technology chemical engineers Warren Lewis and Edwin Gilliland patented an approach for burning fossil fuels in a way that generates a stream of pure carbon dioxide. It did not catch on.

A little over three decades later, though, Japanese chemical engineer Masaru Ishida and his colleagues at the Tokyo Institute of Technology revisited the process, this time as a way to increase power plant efficiency. In a 1987 publication, the Japanese team introduced the name chemical-looping combustion (CLC) for the process, which involves separating combustion into two separate steps.1 Ishida continued to explore CLC and by the 1990s, technologies for efficiently burning fossil fuels to generate pure carbon dioxide were beginning to have an altogether different significance.

Carbon capture is the catch-all term for technologies intended to mitigate climate change by trapping the emissions of carbon dioxide generated by power plants or factories burning fossil fuels. In a conventional power plant, fuels are burned in air, generating a flue gas that, like air, largely consists of nitrogen, with carbon dioxide typically making up less than 15% of the mixture. In order to sequester the greenhouse gas, it first has to be separated out from this mixture – for example, by bubbling the flue gas through an amine solvent that selectively absorbs carbon dioxide. The downside of this approach is that it requires a significant energy input, particularly the requirement to heat the amine solvent to release the captured gas. Overall, amine-based post-combustion carbon capture is predicted to increase energy generation costs by 42–81%.2

CLC avoids the need for complex flue gas separation, instead generating a readily separable mixture of carbon dioxide and water vapour. The great attraction of this approach is that, according to calculations, its energy penalty should be lower than any other carbon capture technology. The increase in energy generation cost for a CLC plant is predicted to be as low as 12%.3

Anders Lyngfelt, a chemical engineer at Chalmers University of Technology in Gothenburg, Sweden, started to work on CLC technology in 1998 after noticing Ishida’s work.4 ‘When I saw this process I immediately started to work on it because I thought it was a very interesting way to approach carbon capture,’ he explains. ‘And I’m getting more and more convinced that we have the solution.’ The spate of medium-scale pilot plants recently started up or soon to be built should soon tell if Lyngfelt is right.

How it works

The key to CLC is to keep all air out of the reactor in which the fuel is combusted. Instead, the oxygen required for the combustion process is supplied by metal oxide ‘oxygen carriers’. By excluding air, the waste gases generated by combustion – carbon dioxide and water vapour – can be collected in nearly pure form. Separating out the water by simple condensation leaves just the carbon dioxide.

Once the oxygen carriers in the combustion reactor are spent, they are transferred to a second reactor where they are exposed to air. Here they rapidly and exothermically oxidise, regenerating the original metal oxide ready to be looped back into the combustion reactor.

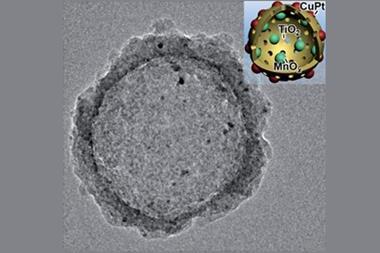

Although separated into two steps, the overall process of combustion, and so the energy available to drive turbines and generate electricity, remains the same. ‘The oxygen carrier is the most critical component of chemical-looping combustion,’ says Martin van Sint Annaland, a reactor engineer working on CLC at Eindhoven University of Technology in the Netherlands. ‘It is the part that is really doing the job.’

For the last decade, Lyngfelt has been at the forefront of new oxygen-carrier material research. Over this time, hundreds of different materials have been tested. Finding metal oxide particles with the right properties is not too difficult, he says. ‘The first materials we tested, we had 98 to 99% fuel conversion and 100% CO2 capture. We ran it for 100 hours and it was a very stable material,’ he recalls. ‘But it was an expensive material.’

And therein lies the challenge with CLC. To achieve its theoretical advantage over rival, more mature carbon capture technologies, the oxygen carrier particles must have high performance, must be robust enough to survive for hundreds of hours while being subjected to redox cycles at high temperatures and pressures, and must be cheap.

Much of Lyngfelt and his colleagues’ early work was centred on nickel-based oxygen carriers. Although nickel itself has just about the highest price of any metal being considered for CLC, the researchers at Chalmers have since developed robust and effective nickel-based oxygen carriers only a little more expensive than the raw material price of nickel itself.5 ‘We ran this material for 1000 hours,’ says Lyngfelt. ‘The concept is proved based on nickel materials – for gaseous fuels.’

Lyngfelt and his colleagues have been developing new oxygen carrier materials using a small, 10kW test reactor built at Chalmers a decade ago. The reactor is based on ‘fluidised bed’ technology. In the combustion reactor, the gaseous fuel enters at the bottom of the reactor with enough velocity to ‘fluidise’ the oxygen carrier particles: friction overcomes gravity so that the particles begin to float. The particles travel up through the reactor until, spent of oxygen, they exit at the top. After collection in a cyclone, the particles are transferred to a second fluidised bed reactor where they are regenerated by mixing with air.

There is a good reason for using fluidised bed reactors for CLC – they are already proven at the scale that will be needed for power plants. Lewis and Gilliland may never be known for carbon dioxide manufacture, but their pioneering role in developing fluidised bed reactors for crude oil refining, to catalytically convert high-boiling hydrocarbons into gasoline, is already well established. Thanks to its long history of use within the oil industry, its use on a huge scale is well understood.

A solid problem

More recently, Chalmers installed a second 10kW CLC fluidised bed reactor, this time designed for solid fuels. Although the process might have proven its potential for natural gas, the real target is to develop CLC for coal, says Lyngfelt. ‘Solid fuel is the big fish to catch. For coal-fired power plants, CLC has enormous potential for reducing costs and the energy penalty of capturing carbon.’

One difficulty with combining CLC with solid fuels such as coal is that they generate ash, which can cause significant attrition of the oxygen carrier particles, shortening their lifespan. This in turn upsets the delicate economics of the process, says Lyngfelt. ‘Nickel material is much too expensive to be used with fuels containing ash.’

The other issue with combining CLC with coal combustion is that it introduces relatively slow extra steps into the process: the in situ breakdown of coal particles into syngas (hydrogen and carbon monoxide). It is these gaseous intermediates that then react with the oxygen carrier particles to complete combustion. Because syngas generation can occur at any point within the combustion reactor, including right by the reactor exit, some syngas will escape unreacted, reducing fuel conversion.

Lyngfelt and his colleagues at Chalmers have developed an alternative process called chemical looping with oxygen uncoupling (CLOU), which employs oxygen carriers that spontaneously release oxygen in the combustion reactor to react directly with the solid fuel.6 ‘Lab testing clearly demonstrates that you can have complete fuel conversion, because there is a slight excess of oxygen produced,’ Lyngfelt says. ‘There are a number of different oxygen carriers with CLOU properties, of differing prices and differing abilities to release oxygen. The highest rates of oxygen release are with copper materials, which are also the most expensive.’

It is economics that has prompted Liang-Shi Fan, a researcher at Ohio State University in Columbus, US, to focus on iron-based oxygen carriers. ‘You have to think of oxygen carriers in terms of the cost, and the cheapest one is iron,’ he says. ‘Iron is not perfect, its reactivity is not as high as nickel, but it serves the purpose. For a commercial reactor, iron oxide is reasonable in terms of the reactor sizes that will eventually be used.’

As at Chalmers, Ohio State has its own test reactor, a 25 thermal kilowatt (kWth) unit designed for solid fuels. The reactor is not based on fluidised bed technology, but rather on a process called countercurrent moving bed. Although the fuel still enters from the bottom of the reactor, the oxygen carrier enters at the top, and slowly passes down through the reactor owing to gravity. This has a couple of advantages for the reactions taking place within the reactor, says Fan. It ensures that essentially all carbon monoxide near the top of the reactor gets fully oxidised to carbon dioxide before it exits at the top, thereby fully using the fuel. Meanwhile, at the bottom of the reactor, the entering fuel fully reduces all of the iron(III) oxide oxygen carriers down to a mixture of iron and iron(II) oxide, making most efficient use of the oxygen carrier.

‘We have just finished 200 hours of continuous operation of chemical-looping combustion,’ says Fan. ‘This is the longest continuous run ever demonstrated in the world, indicating a strong chemical-looping technology commercialisation potential,’ he adds. ‘The coal can be converted at 99.9%, and the exit gases do not contain carbon monoxide or methane.’ This is a key advantage over the fluidised bed approach, says Fan. ‘With fluidised bed, 10–15% carbon monoxide leaks out, and they need another step to convert carbon monoxide and methane into carbon dioxide.’ The extra steps required for fluidised bed methods add to the complexity, and the cost, of building an operating a power plant.

Cheap as chalk

But Paul Fennell, a researcher at Imperial College London, UK, is working on something potentially even cheaper than Fan’s iron-based approach: calcium carbonate, or limestone.7 The raw performance of calcium carbonate is far below that of nickel-based oxygen carriers, particularly when it comes to particle lifetime. The big advantage of using limestone is that, although its oxygen-carrying capacity drops off after a relatively low number of cycles, the exhausted oxygen carrier material, calcium oxide, potentially has a use, as an advanced intermediate in the production of cement.

Conventional cement manufacture is an energy-intensive process with a carbon footprint to match. Portland cement consists largely of calcium oxide, produced by heating limestone to over 1000°C. This reaction liberates one molecule of carbon dioxide for every molecule of calcium oxide produced, on top of that released by burning fuel to heat the kiln. By using material from a chemical-looping combustion process, this entire process can be skipped.

Pure limestone will work as an oxygen carrier, but Fennell is searching for cheap ways to modify it for better performance, while still leaving an exhausted material suitable for cement manufacture. ‘We’re looking at doping the limestones with different materials to enhance long-term reactivity,’ he says. ‘So far we’ve about tripled the long-term reactivity with very cheap doping methods. I think we could go a bit further.’

Fennell is involved in demonstrating calcium looping at the pilot scale, in a 1.7MWth EU-funded project in northern Spain called the CaOling project. ‘The initial results from that are extremely promising,’ he says.

CaOling is just one of the pilot plants recently built or soon to be completed to test the feasibility of looping combustion technologies at scale. Several competing reactor technologies are in the process of being tested at a similar scale – including a 1MWth version of the fluidised bed reactor developed at Chalmers, which commenced operation in 2011 at the Technical University of Darmstadt in Germany. And in the US, Fan and his colleagues are in the process of designing a plant to test their countercurrent moving bed concept at a scale of several MWth.

Under pressure

Van Sint Annaland has another reactor design in mind. Whereas the fluidised bed reactors used in the refining industry operate at atmospheric pressure, theoretical calculations predict that, to operate at maximum efficiency, CLC should be carried out at about 1200°C and 20 bars of pressure. This complicates the handling of the solid oxygen carrier particles, says van Sint Annaland. ‘Due to fluidisation, the particles will collide and that will cause particle attrition, creating very small fines. To separate these at 20 bars is very difficult, but absolutely necessary; otherwise, the downstream turbine would be sandblasted.

‘We thought about a different concept,’ van Sint Annaland adds. ‘You could keep the solid stationary, and change the gas composition above the fixed bed, so you feed air until the particles are all oxidised, then you cycle to the next step in which you reduce the bed with the fuel. The advantage is you don’t have a problem with gas–solid separation.’ Fixed-bed technology is already used in industry for high pressure processes, he adds, including hydrogen production. A 0.5MWth pilot CLC plant is being built in Puertollano, Spain.

Of all the reactor concepts currently in testing, which one will win out remains to be seen. ‘Within five years we should have some operational knowledge on the different concepts,’ says van Sint Annaland. ‘It will be the economics that decides the outcome. I think that the decision on what technology is in the end preferred might be very subtle.’

But when it comes to whether the technology will ever be implemented at all, he says ‘I think that is a political question. A company will never invest in novel technology unless there is a penalty on carbon dioxide emissions.’

James Mitchell Crow is a science writer based in Melbourne, Australia

References

1 M Ishida, D Zheng and T Akehata, Energy, 1987, 12, 147 (DOI: 10.1016/0360-5442(87)90119-8)

2 Carbon Dioxide Capture and Storage, Bert Metz et al (eds), Cambridge University Press, UK, 2005

3 J Adanez et al, Prog. Energy Combust. Sci., 2012, 38, 215 (DOI: 10.1016/j.pecs.2011.09.001)

4 M Ishida and H Jin, Energy, 1994, 19, 415 (DOI: 10.1016/0360-5442(94)90120-1)

5 A Shulman et al, Ind. Eng. Chem. Res., 2009, 48, 7400 (DOI: 10.1021/ie900342f)

6 T Mattisson, A Lyngfelt and H Leion, Int. J. Greenhouse Gas Control, 2009, 3, 11 (DOI: 10.1016/j.ijggc.2008.06.002)

7 C C Dean et al, Chem. Eng. Res. Des., 2011, 89, 836 (DOI: 10.1016/j.cherd.2010.10.013)

No comments yet