Surrounded by narrow lanes in the Clerkenwell district of London, near St Paul’s Cathedral, stands an impressive, three-storey, 180-year-old hall that houses the Goldsmiths’ Company. Beyond its entrance is a red-carpeted double staircase surrounded by walls and columns in 10 different shades of marble. Marble statues of four children representing the four seasons stand atop large pedestals, and exquisite precious metal artefacts, such as a 14th century goblet, sparkle under lights within glass cabinets. The stairs lead up to magnificent rooms.

One room is beautifully decorated in red and gold and has Corinthian columns of scagliola. From its high ceilings decorated in gold leaf are suspended four massive and ornate 19th century chandeliers. The walls are clad in oak panelling and on them hang many different shields, each representing the different coats of arms of the members of the Goldsmiths’ Company, past and present. This is the Livery Hall. It is here that a trial jury gathers each year to deliver its verdict at the Trial of the Pyx, a coin integrity test, one of the many roles of the Goldsmiths’ Company Assay Office.

History in the making

When Edward I passed a law that stated that any item made of silver that was offered for sale should be at least equal in quality to the silver coins of the realm in 1300, the Goldsmiths’ assay office was founded. Its wardens would visit workshops in London to assay silver articles, and if any were found to be less than 92.5% minimum silver content, they were destroyed and the metal forfeited to the king. When articles passed the test, they received the king’s mark of authentication, which was a leopard’s head. This mark is still used by the assay office today to mark metals, along with the sponsor’s mark and the millesimal fineness mark. This is known as hallmarking, a term that originated from the process of being struck with the king’s mark at Goldsmiths’ Hall.

Today, the assay office tests and hallmarks around 4 million gold, silver, platinum and palladium articles each year. ‘It’s our job to uphold the 1973 hallmarking act, which states that any article made of precious metal must be tested and hallmarked by law before it is offered for sale in the UK,’ says laboratory manager Chris Walne, who has worked at the assay office for 28 years. There are two exceptions to the law: coinage of the realm and bullion do not need to be hallmarked. However, ‘we do mark bullion but it’s our own unique reference number with the assay office logo at each end and we issue an assay certificate,’ explains Walne.

The assay office is on the top floor of Goldsmiths’ Hall, and it couldn’t be more different to the rest of the building. Leaving behind the grand urban palazzo style of decoration, there is a series of narrow white-walled corridors leading to the stairs and lifts that take you up to the modern surroundings of a laboratory. The contrast between the old and the new is as apparent within the laboratory as it is between the bottom two floors and the top floor. It’s a big laboratory, split into three sections. In the first, many people sit at long benches, hammering metals with a hammer and punch. In the next room, there is more sophisticated-looking equipment for hallmarking, then there’s a smaller laboratory that accommodates analytical test equipment.

Hallmarking

A hallmark guarantees the purity of the precious metal content of an article. Three compulsory marks must be stamped onto an item – the sponsor’s mark (usually the manufacturer’s initials), the assay office mark, and the fineness mark, which denotes the minimal finest purity (for example 925 parts per thousand is sterling silver and 375 parts per thousand is nine carat gold). ‘There are voluntary marks, too, such as a lion for sterling silver and an Athena’s head for palladium,’ adds Walne, ‘and there are stamps for each year, done in sequential order. For 2016, the letter R was used.’ There are four assay offices in the UK. Each has its own mark: London – the leopard’s head, Sheffield – a rose, Birmingham – an anchor, and Edinburgh – a castle.

At the London assay office, they use three techniques to apply hallmarks. ‘We employ a traditional hammer and punch technique, literally striking the mark into an item with a hammer and punch, which displaces the metal. That’s the most skilled technique,’ says Walne. ‘We also have automatic press markers for marking large batches of articles quickly. The most up-to-date method is the laser marker, which etches a very defined two- or three-dimensional hallmark.’ The advantage of the latter method is that the metal is not displaced so the mark can be applied to surfaces as small as 0.3mm.

Customers from all over the world use the laboratory’s service, which is considered a centre of excellence. Their general customer base is retail jewellers, manufacturing jewellers, bullion dealers and bullion traders. ‘We get a lot of bespoke commission work from people such as Damien Hirst and Vivienne Westwood. We also take care of quite a few sporting trophies, such as horseracing trophies and football trophies.’ The assay office tested and marked the gold and silver medals awarded at the London Olympics in 2012.

To help train the jewellery makers of the future in this highly skilled art, the Goldsmiths’ Company has a centre in Clerkenwell with workshops to rent out to goldsmith and silversmith apprentices, with expertise on hand to guide them. And at the assay office, they give chemical analysis training to staff from assay offices in other countries that haven’t necessarily got the expertise, says Walne.

Analysis tests

The assay office uses four main analysis techniques – x-ray fluorescence spectroscopy for jewellery alloy determination, fire assay cupellation for gold and/or silver analysis, potentiometric titration for silver and inductively coupled plasma emission spectroscopy for trace element determination. They receive samples in a variety of forms for testing, which can include raw materials, scrap metal, jewellery sweeps and lemel (small shavings of precious metals that are left over from, for example, filing jewellery pieces).

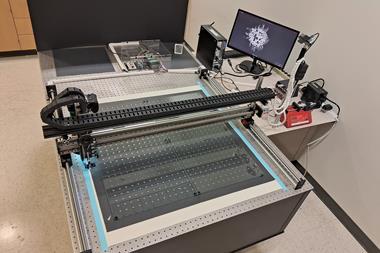

The predominant method used for testing finished articles of jewellery is x-ray fluorescence spectroscopy, which analyses jewellery alloys prior to hallmarking. It is a quick and non-destructive way to analyse a metal alloy’s surface and is used as a screening tool to determine an alloy’s composition prior to chemical analysis with appropriate standards, explains Walne. Primary radiation is generated from an x-ray tube, which is fired at the alloy. The radiation excites the atoms in the alloy, which then emit fluorescence radiation. This radiation shows up as a graph of energy distribution peaks on a computer screen. Each alloy is characteristic in its energy distribution for a particular material, so the element composition can be identified and quantified by the intensity, says Walne. Unknown samples are tested against certified reference standards of different carat alloys and the assay office can attain an analytical result +/–0.5% with their current device. They regularly check their results testing daily quality control samples and cross checking suspect items against the referee chemical method – fire assay.

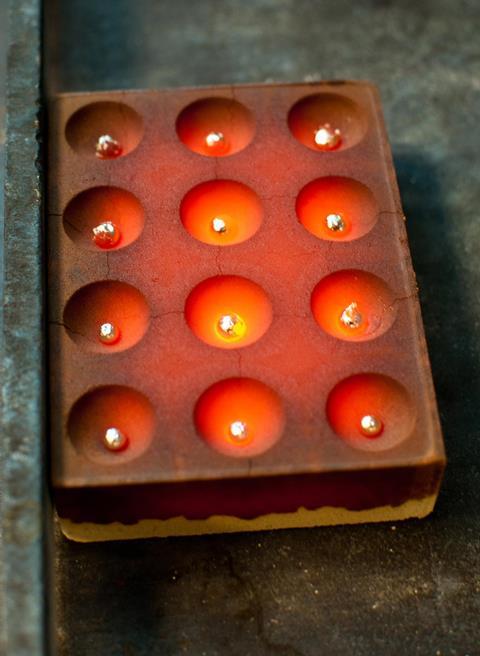

Watching the 2000-year-old fire assay cupellation technique in action in a modern laboratory is fascinating. Fire assay cupellation is a small-scale refining process to separate gold from other elements in an alloy to calculate the gold content by weight. Small metal alloy samples are melted in pure lead and then the base metals from the sample are removed by an oxidising process. This is done in a cupellation furnace heated to 1100°C. The lead-encased samples are placed in trays called cupels made of magnesium carbonate. 2000 years ago, says Walne, they used bone ash. Walne placed the trays of cupels into the furnace to heat for 20 minutes. Then, using a large paddle with a long handle, he brought out the red hot cupels and placed them down to cool for 15 minutes. As they cooled, the cupels appeared to have turned green, and Walne explained that this was the oxides of the base metals being absorbed by the cupels. Left behind in the cupels were little metal beads containing just the precious metals – silver and gold. These now needed to be made ready for the next stage.

To do this, Walne quickly flattened each tiny metal bead into discs about the size of a watch battery using a pressing machine. He then softened them in the flame of a Bunsen burner before dropping them through a metal funnel into a rolling mill to flatten them further into ellipse shapes. He softened them again in the Bunsen flame before rolling up each metal ellipse. This, he says, is to increase their surface area for the next stage. He then dropped each rolled up piece of metal into individual small sample tubes in a platinum tray to be lowered into nitric acid. This process removes the silver portion of the alloy to leave the gold at the end to be weighed.

To analyse silver content greater than 750 parts per thousand in silver alloys, the standard method used by the laboratory team is an acid/base titration. The team dissolves samples in nitric acid to produce a silver nitrate solution. Then they add a standardised amount of sodium chloride to the silver nitrate, which produces an electrical potential between Ag+ and Cl–. This can be detected by the electrodes in the solution and the team calculates the pure silver content based on the volume added and the original sample weight.

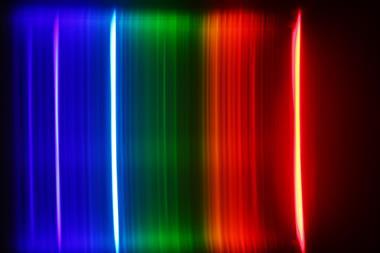

The final technique in use here is inductively coupled plasma optical emission spectroscopy, which quantitatively analyses platinum group metals and other transition metals in a metal alloy. Walne explains that they dissolve samples in acid, usually aqua regia, and make up the solution to a known volume. They introduce the solution into the spectroscopy instrument to measure the concentration of the elements in the solution. Within the instrument is an argon plasma energy source, which generates a temperature of 8000°C, and excites the atoms of each element such that they give off ultraviolet and visible light radiation at certain wavelengths. The team can then identify each element and quantify it by its intensity via peaks on a graph.

Trial of the Pyx

Every year, the assay office staff use their analysis techniques to ensure the integrity of new coinage produced by the Royal Mint in Llantrisant, Wales, for the Trial of the Pyx, which is carried out in a formal court of law. The trial began in the 12th century, making it the oldest judicial procedure in the UK. Early trials were held at Westminster Hall, followed by the Exchequer at Westminster, but since the 1870 Coinage Act, have been held at Goldsmiths’ Hall, lessening the journey between the assay office and the trial room. The Pyx, derived from the Latin pyxis meaning small box, is the chest in which coins are transported from the mint to the assay office.

Today, the coins tested are for use in circulation, and commemorative and collectors’ coins (some of which are large – about the size of a hand – and heavy, and have denominations of up to £1000). Each February, the assay office tests over 50,000 coins from a random sample from each denomination for metallic composition, weight and size, which must be within statutory limits. The coins arrive in sealed bags containing 50 coins each, locked in the wooden Pyx boxes, which are about the size of a small suitcase. The benchmarks against which the coins are measured are trial plates; there is one for each precious and base metal being tested (pure platinum, gold, silver, copper, nickel and zinc).

The assay office takes samples for testing from the coins by drilling out three or four parts from all over the coin (the assay office has special permission to deface coins). ‘The testing takes two to three months to complete, then in May, the Trial of the Pyx verdict is read out,’ says Walne. This is held in the Livery Hall, with a jury comprising members of the Goldsmiths’ Company presided over by the Queen’s Remembrancer (the senior judge) of the Royal Courts of Justice. The verdict is read out by the clerk of the Goldsmiths’ Company, with the chancellor of the exchequer in attendance. No coins have failed the test since Walne started his role at the office. Theoretically, though, if a coin did fail, ‘it’s a traditional ceremony and the ruling is that the chancellor is on trial. If any of the coins were to fail based on our assay, then traditionally, he would have his head chopped off!’

No comments yet