Researchers recover and reuse waste gold nanoparticles

A group of US chemists has developed a straightforward method to recover and recycle gold nanoparticles from nanomaterials waste.1

The market share for gold nanoparticles is expected to increase exponentially in the next years, as they have applications in areas like medical diagnostics, storage devices and solar cells. Gold is expensive, and researchers have been developing ways to recover gold from waste. However, most methods require toxic chemicals such as mercury or cyanide.

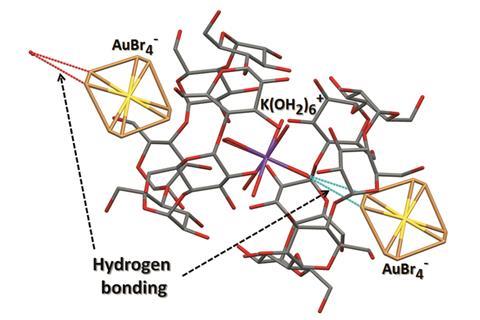

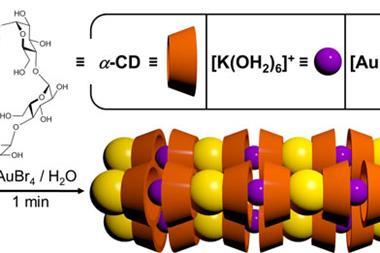

Now, a team led by Peter Vikesland at Virginia Tech in the US has adapted a gold recovery method first developed by recent Nobel prize laureate Sir Fraser Stoddart2 to capture gold nanoparticles from waste. First, Vikesland’s team treated the nanoparticle waste with potassium chloride, hydrobromic acid and nitric acid, which converts any gold into [AuBr4]-. Then, they added environmentally friendly α-cyclodextrin, a large circular molecule made up of sugar units, which traps and precipitates the metal. The gold–cyclodextrin complex can then be filtered, the gold extracted and reduced to its metallic form, ready to be reused.

Although Vikesland’s method is a lab-scale proof-of-concept, it is versatile and even allows researchers to recover gold from alloy scraps and electronic waste. The study shows that recycling strategies can reduce the environmental impact of nanoparticle synthesis.

This article was edited on 11 October 2016 to reflect that Vikesland’s method uses a gold recovery technique adapted from Liu et al.2

References

- P Pati, S McGinnis and PJ Vikesland, Env. Sci.: Nano, 2016, DOI: 10.1039/C6EN00181E (This article is free to access until 14 November 2016)

- Z Liu et al, Nat. Commun., 2013, 4, 1855 (DOI: 10.1038/ncomms2891)

No comments yet