Ionotronic materials are beginning to show how life’s signals can be aligned with electronics. James Urquhart speaks to the scientists who are exploring the emerging frontier

Every second, electricity flows through the soft, flexible, water-filled cells of living organisms. This electricity enables us to think, move and experience the world and it happens thanks to ions: atoms and molecules carrying positive or negative charge. When our senses are stimulated, ions are triggered into motion across cell membranes, precisely controlled by protein channels, generating an electrical current that fires signals along nerves to the brain.

Conversely, electronic devices – smart phones, computers, displays, you name it – rely on electricity produced by the interaction of negative electrons and positive holes along metal wires embedded in rigid materials. It would seem that ionic and electronic circuits and materials are worlds apart. But to an extent, ions and electrons have co-existed in certain devices for decades, such as batteries, supercapacitors and electrochemical cells. These all rely on ionic and electronic charges interconverting. What’s new, however, is that ionic and electronic signals are increasingly being united with flexible and stretchy conducting polymers, known as ‘ionotronic’ materials.

Nature has only one flavour of electron, but nearly an infinite number of ions

‘Over the last two decades or so people have started to realise that ions offer opportunities for producing unconventional effects,’ says Ryan Hayward who investigates soft polymer materials at the University of Massachusetts in the US. ‘Nature has only one flavour of electron, but nearly an infinite number of ions. This means that functionalities could be attached to ions that influence optical characteristics, surface energy, or even bioactivity of a material.’

A growing number of studies are revealing just how the world of ions and electrons can be integrated, offering tantalising glimpses into what merging living matter with machines could look like in years to come. Ionotronic materials can respond to environmental changes in life-like ways, which could be a crucial step in the integration of humans and machines. Such technology could ultimately lead to anything from bionic soft robots, intelligent wearable sensors and cyborg tissues all the way to human–computer interfaces, electronic plants and digital control of biomolecules. So how are researchers going about bringing ions and electrons together?

Brain waves

‘In a sense we want to teach electronics a foreign language: the language of ions,’ says George Malliaras, who investigates brain interface bioelectronics at the University of Cambridge, UK. ’We operate in a very foreign environment to electronics. Mixed conductor materials can do the translation and enable communication between the world of biology and the world of micro-electronics.’

One mixed conductor that has gained ground in recent years is a flexible, biocompatible conducting polymer called Pedot, or poly(3,4-ethylenedioxythiophene), doped with PSS, or poly(styrene sulfonate). The Pedot part provides the electrical conductivity of the conjugated polymer, while PSS allows ionic transport. The formation of an electric double layer at internal interfaces between ionic and electronic conductors essentially allows the signals to be coupled.

Malliaras’ group has developed devices with thin films of Pedot:PSS to find novel therapies and treatments for brain injuries and disease. As a member of BrainCom – an EU collaborative research project developing neuroprosthetic devices to restore communication in patients – Malliaras works on minimally invasive mixed conductor electrodes and transistors for decoding brain signals into speech using electrocorticography (ECoG).

If you implant a device into the brain, you’re now past the blood–brain barrier

ECoG usually uses millimetre-wide metal electrodes that record averaged signals arising from many neurons. Such electrodes are used on patients with impaired speech, including those who have locked-in syndrome. By placing them on the part of the brain cortex that deals with language and asking patients to imagine words, the resulting ECoG recordings can be processed by computer algorithms to predict the words and vocalise them through a speech synthesiser.

But with systems like Malliaras’ that use a mixed conductive polymer, the electrodes can be much smaller – just a couple of microns across – and can be precisely placed on the brain’s surface to capture individual neural signatures, which represents a new capability for ECoG. Now in preclinical trials, Mallarias’ electrodes could offer a huge leap in the quality of speech production. They could also offer a better neural connection for prosthetic limbs and exoskeltons controlled by the user’s brain.

As well as translating ionic signals, however, Malliaras wants to deliver drugs – many of which can be in an ionic form – using implantable ionic devices that pump ions under an electric field via electrophoresis. ‘Drug delivery in the brain is a challenge because you have the blood–brain barrier that blocks about 98% of all pharmaceuticals that we have available,’ he explains. ‘If you implant a device into the brain, you’re now past the blood–brain barrier and so, all of a sudden, you can use a much larger gamut of drugs.’

What’s more, because such devices can deliver drugs directly to the affected region, only tiny amounts of a drug is needed. This means that drugs that are normally too toxic to be administered systemically, into the bloodstream for example, could now be used. Malliaras and co-workers have recently designed a microfluidic ion pump device that transfers ions of a drug from a reservoir to the brain, mimicking synaptic transfer in cells. They demonstrated it could stop and prevent epileptic seizures in mice (https://advances.sciencemag.org/content/4/8/eaau1291). The concept is now being broadened to target brain tumours with chemotherapy drugs, Malliaras says.

Plant implants

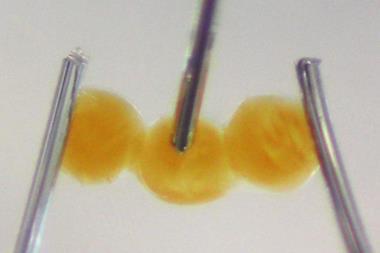

Similar ion pump devices are being used to communicate with and control plants too. Last year Eleni Stavrinidou and colleagues at Linköping University in Sweden successfully implanted a bioelectronic device into a living plant for the first time. The organic electronic ion pump is based on tiny glass capillary fibres and was implanted into the soft tissue of a tobacco plant leaf.

This enabled researchers to precisely control and deliver pure abscisic acid ions – a hormone which naturally regulates plant response to stress – into the leaf at the cellular level. The results offered fresh insight into how the hormone triggers the closure of pores in the leaf that are responsible for photosynthesis and transpiration.

‘How plants respond to environmental stress is important to know, especially in these times of climate change where we have a lot of drought or high heat or extreme weather phenomena,’ says Stavrinidou. ‘We’re hoping that with our technology we can make more kinetic and dynamic studies possible to better understand plant physiology.’ Doing so could help optimise crop growth or guide genetic modifications to improve how plants use water.

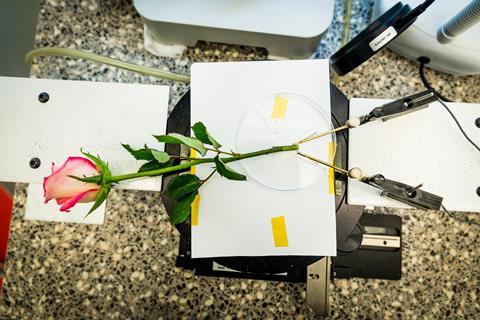

Merging electronics with plants is nothing new to Stavrinidou, though. In 2015 she and her colleagues turned roses into living electronic circuits with a conducting Pedot-based material. To achieve this, they fed cut plants a solution containing the polymer. Once inside, the plant’s water-transporting xylem provided a tubular template, while its biochemical response organised the polymer into hydrogel-like wires in the stem.

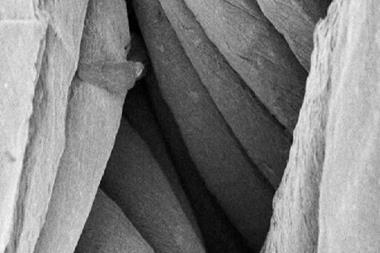

The team has since developed this further by designing a new water-soluble oligomer called ETE-S made using functional units of EDOT (the monomer unit of Pedot) that were inserted as external end groups to thiophene butyric acid. The team found that due due to its small molecular size ETE-S polymerises and distributes to every part of the xylem in a rose, thus connecting the whole plant – from roots to flower or leaves – with conducting wires. It does so by triggering the catalytic cycle that usually produces lignin in plants for structural support. By hacking this biochemical pathway, ETE-S uses the enzyme peroxidase to catalyse its polymerisation, becoming integrated into the cell walls.

Due to an interplay between electronic and ionic conductivity, the researchers showed that plants could be turned into transistors and supercapacitors that could store energy in the form of ionic charge. It needs further work to stabilise the charge but it’s an interesting proof-of-concept. ‘We’re now working on ways to harvest energy from the plant in the form of the sugars and convert them back to electricity,’ explains Stavrinidou.

The concept could form the basis of energy harvesting technologies that use plants, possibly even trees, to store and dispense energy as bio-factories. Meanwhile, ETE-S could allow sensors and delivery devices to be constructed inside plants that could be used to electronically regulate them. ‘It’s hard to predict where this will go – there are a lot of new directions to explore,’ says Stavrinidou.

Soft and stretchy

Tissues and organs are essentially made of hydrogels – think tofu or gelatin – essentially ionic solutions containing a solid-like polymer network. Synthetic hydrogels were first invented in the 1960s and have since been used in applications as different as contact lenses, superabsorbent disposable nappies, and more recently, artificial tissues. However, researchers have begun making them conductive using conducting polymers such as Pedot:PSS. Along with being biocompatible, self-healing, transparent and stretchy, it makes these materials desirable for many applications including artificial muscles, skins and synapses, rewritable displays and flexible batteries.

Striking the perfect balance between high conductivity, biocompatibility, robustness and stretchiness has been hard to achieve, however. One property tends to lose out over the others making it a serious limitation for realistic applications. But researchers like Xiaodong Chen, who develops bioinspired materials at Nanyang Technological University in Singapore, are striving to overcome these challenges.

Chen recently developed tough, rubber-like ionotronic hydrogel wires, made from a stiff and dense polyvinyl alcohol (PVA) hydrogel that provides mechanical strength. After this was soaked in a sodium chloride solution, it was embedded with biocompatible hydroxypropyl cellulose fibres to enhance ionic conductivity while also tuning the mechanical properties. By varying the ratio of cellulose fibres and the level of salt soaking, the mechanical and electrical properties could be easily tuned for the required scenario; for example, to mimic a specific type of tissue.

The researchers tested it as an artificial ligament by 3D printing a robotic hand and inserting a hydrogel wire into its index finger. Even though the wire was stretched when the robotic finger was bent, it continued to supply current to light up an LED at the fingertip. ‘This means it can transfer a steady AC signal under expansion, guaranteeing the continuous monitoring of muscle movement,’ Chen explains. It could work as an artificial nerve too, as the team showed by integrating a pressure sensor to the fingertip to mimic the neural process for touch sensing. It showed how different touch signals were produced in the LED when the hydrogel was stretched to varying degrees due to the flexing finger.

But ionotronic hydrogels always require some form of electronic conduction to seamlessly connect to external equipment. This usually means loading them with additional stiff materials, further compromising the hydrogel’s softness and stretchability. Chen has tackled this by developing a hydrogel–elastomer hybrid material – akin to connective tissue that joins soft tendons to hard bone. The result is highly stretchable electrodes that bridge the gap between soft ionotronics and rigid electronics.

The hybrid material comprises porous elastomer webs of thermoplastic polyurethane containing conducting gold nanofilms. By soaking this in a hydrogel precursor and curing it with heat, it produced mechanically soft, self-adhesive and highly conductive electrodes. ‘As a proof of concept, we demonstrated that the hybrid electrodes can be used as on-skin electrodes with high fidelity for electrophysiological signal recording including electromyography and electrocardiogram,’ says Chen.

Solid state

But while hydrogels show much promise, they have other drawbacks. Their longevity and reliability are vulnerable to evaporation of the liquid electrolyte as well as potential leakage, which is particularly prone to happen in devices that are designed to be stretched or deformed.

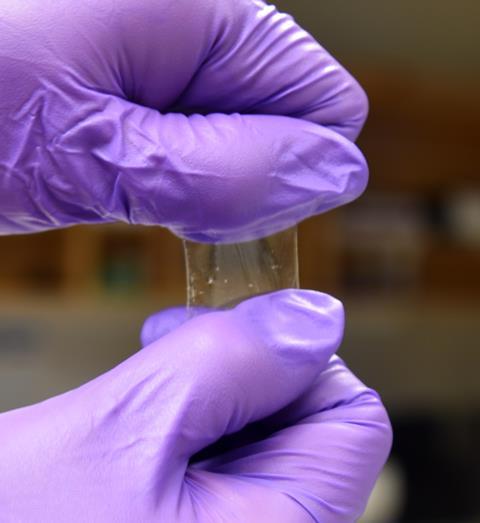

Hayward and his co-workers, however, have a different approach. Instead of hydrogels, they have developed stretchy ion-conducting elastomers, or ionoelastomers, that are completely solid state; no liquid electrolytes required. ‘Our material relies on soft networks of charged polymers where the counterions are the only mobile species,’ he says. ’In addition, our devices operate without requiring any electrochemical reactions, which can alleviate issues of long-term device instability.’

The team made two ionoelastomers – a polyanion and a polycation – that resemble a rubber band or a thread of Lycra. In the polyanion, negatively charged sulfate groups are fixed to the elastomer chain while positive imidazole counterions can move freely in response to concentration gradients or electric fields. In the polycation, this is reversed – the negative ions are fixed while the positive ions can move.

This means that each ionoelastomer conducts only positive or negative charge, akin to p- and n-type semiconductors that transport holes and electrons respectively. Discovering this, Hayward’s team set out to see if the ionoelastomers could form ionic devices that are analogous to components of electronic circuitry. The researchers found that when two opposing elastomer layers were brought together to form a junction, they behaved like a diode, allowing current to pass in one direction but not the other. They also created a transistor by sandwiching a polycation layer between two polyanion layers that could switch currents. Such devices could form the basis of ionic digital logic and memory akin to electronic computing.

‘Ions will probably never come close to competing with electrons as far as speed or spatial density is concerned, but there are a number of possible advantages to using ions for transporting signals and doing computation in materials,’ says Hayward. ‘The devices continue to operate when deformed but their characteristics change, meaning that there may be interesting ways to use the coupling between mechanics and ionic responses to develop new types of sensors or control elements.’ What’s more, the team unexpectedly found that an electrical output signal was produced when the ionoelastomer was stretched and compressed, suggesting that it could be used to harvest mechanical energy from our own movements or from the surrounding environment.

However, Hayward is particularly intrigued about another of the ionoelastomer’s unexpected properties: electro-adhesion. His lab’s latest work showed that opposite ionoelastomers can be reversibly and rapidly stuck together with as little as one volt. That’s a huge difference considering that other electro-adhesives typically operate at around 1000V, which presents safety concerns, requires specialised circuit elements, and can lead to catastrophic failure. Hayward’s finding holds promise for safe, efficient and robust actuator systems that could enable soft robots to handle delicate objects.

Such applications may be far off and it’s still early days for ionontronics. But the word electronics only started to be used in the 1940s. If the current pace of emerging of ionotronic materials is anything to go by, who knows what life-mimicking technologies they could eventually enable?

‘It’s hard to say at this point where these materials will ultimately lead – we started this work mostly driven by curiosity to see if we could develop a new class of soft ionic conducting devices,’ says Hayward. ‘But I don’t think anyone could have predicted what would happen with electronic devices when they started out, so I like to think that in the years to come we’ll see some really remarkable new applications with these materials.’

James Urquhart is a science writer based near Edinburgh, UK

No comments yet