MoA Technology leverages CDD Vault cheminformatics system to manage high-throughput herbicide screening data and external collaborations effectively. Here’s how

Agritech companies developing new herbicides generate and analyse huge amounts of data. Data from high-throughput screens, chemical optimisation work, plant genomics, bioefficacy and crop safety testing must be combined to pick candidates for development. Later, promising candidates must pass stringent mammalian toxicology and environmental safety evaluations.

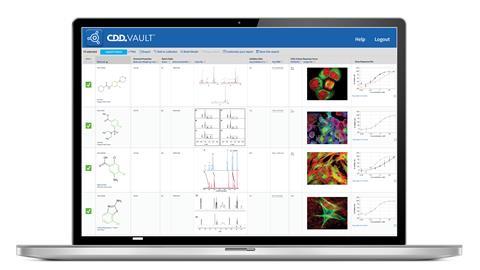

Startup and virtual companies commonly outsource synthetic chemistry, field, glasshouse, physicochemical and regulatory studies to contract research organisations (CROs), which adds another layer of complexity to data management. Ultimately, outsourcing works best if CROs and other collaborators have access to secure two-way information flow without compromising IP, data security or data quality. MoA Technology, an agritech startup, has found CDD Vault – developed by Collaborative Drug Discovery – to be the ideal informatics infrastructure to manage a wide range of data, seamlessly integrating in-house workflows and third party projects.

MoA Technology was established in 2017, spun out from the University of Oxford’s Department of Plant Sciences with a mission to find and commercialise safe herbicides with novel modes of action. Weeds can reduce crop yields by one third and with no significant new modes of action commercialised for more than 30 years herbicide resistance now threatens global food security. Resistance is present in more than 250 weed species infesting nearly 100 crops and affecting most current herbicide modes of action,1, 2 says the International survey of herbicide resistant weeds.

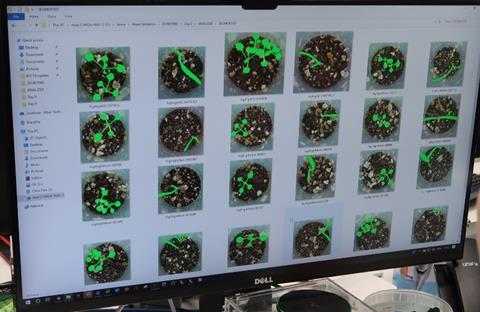

‘Developed by University of Oxford professor Liam Dolan and MoA Tech’s co-founder Clément Champion, this innovative approach is based on an in vivo whole plant model and artificial intelligence,’ explains MoA Technology’s chief technology officer Shuji Hachisu. ‘Our technology uses high-throughput screening previously only used with in vitro systems and with disappointing results. Actually seeing herbicidal symptoms on whole plants enables us to quickly identify promising candidates, elucidate their precise mode of action and find unexplored families of safe and effective chemistry. MoA Tech’s unique approach includes a fusion of three complementary platforms known as MoA Galaxy, MoA Target and MoA Select. When used sequentially, the three platforms allow progression from initial screening of potentially millions of compounds to glasshouse testing and global field trials within months.

Herbicide needles in a high-throughput haystack

At the forefront of MoA Tech’s approach to discovery is MoA Galaxy, a proprietary platform that makes it possible to carry out high-throughput in vivo screening of potentially millions of compounds annually. The key is a plant model with a unique profile including a rapid life-cycle. Cutting-edge imaging technology, digitisation and machine learning capture and analyse the spectrum of symptoms produced.

With just one screening system we can discover herbicide chemistry with novel modes of action

While traditional high-throughput herbicide discovery screens typically allow a simple progress or reject decision, MoA Galaxy generates phenotypic data at the population, single organism, cellular and subcellular levels. ‘This gives us an early view of compound potential and an indication of mode of action, including previously unknown mechanisms,’ says Hachisu.

Smart management for huge datasets

Critically, as a fast-moving young company, MoA Tech required a flexible, scalable web-hosted informatics platform that could help manage multiple data streams. ‘We needed an out-of-the-box user-friendly platform; a solution capable of handling huge amounts of data, with an electronic lab notebook (ELN) that could cope with rapid growth,’ Hachisu says.

MoA Galaxy generates huge datasets that need contextualising with other data. Then there are also chemical optimisation data and results from later regulatory studies. Third parties are important too. Plant genome sequencing, glasshouse testing and regulatory work is outsourced to CROs; compound management providers supply libraries; and chemists synthesise batches of the most promising compounds for further testing. Information flow to and from multiple stakeholders must be secure and allow the company to protect its IP. MoA Tech had to be confident that it could create access for third party off-site users, offer a user-friendly interface and retain complete security.

Ticking all the boxes

After reviewing a number of potential technologies MoA Tech tested a CDD Vault and quickly realised its advantages as an informatics platform. ‘Without any expert help on installation or routine use, we were able to set up and start using the hosted CDD Vault platform as a database for managing the huge volumes of data that our technologies generate,’ Hachisu adds.

CDD Vault acts as the central repository for the data and metadata generated by MoA Tech

‘We needed an informatics infrastructure that could offer a database to hold vast numbers of images and other screening data, act as a compound management platform, offer an ELN and give us a safe, secure system through which to communicate and share data with our CROs and other partners. It was a tall order that CDD Vault fulfills impeccably, whatever we throw at it,’ Hachisu adds.

MoA Tech has set up a primary CDD Vault that acts as the central repository for the data and metadata generated by MoA Galaxy, MoA Target and MoA Select platforms, and from downstream glasshouse and field trials, plus all synthetic chemistry workflows.

While pharma companies focus on the efficacy and safety of new drug compounds specifically on humans, crop protection companies not only have to assess the efficacy of candidate herbicides on target weeds, they also have to assess crop selectivity and potential toxicity to non-target organisms including mammals, fish, insects, even to other plants - and to the environment, including aquatic safety. Some of this work is conducted in-house, but much of the experimental and predictive health and environmental toxicity and safety work is carried out by specialist CROs. ‘At MoA Tech, we use CDD Vault to communicate directly with many CROs, including, synthetic chemists, toxicology assay specialists, glasshouse and field trial partners,’ says Hachisu. All data is housed directly in the primary CDD Vault.

Because CDD Vault and the ELN are so secure, we can set up user accounts for our CRO partners

‘CROs are given authorised access to the vault by project, meaning MoA Tech scientists can easily create and share detailed experimental protocols with CROs through the in-house ELN used to generate and record experiments and standard operating procedures, or SOPs. CROs perform the requested experiments using the compounds and protocols provided. All results, including plant symptoms and images and other experimental data, are uploaded to the CDD Vault directly and securely. CDD Vault acts as a secure, easy-to-use data repository from which data can then be viewed or analysed via third party tools.’

Importantly, the primary CDD Vault also acts as MoA Tech’s dedicated compound management platform. Screening libraries are ordered and tracked, and batches of specified compound structures requested for synthesis by the firm’s chemistry providers in Europe and China are ordered and registered. When sufficient compound supplies are received, the system alerts key personnel to initiate glasshouse trials by third party CROs, keeping delays to a minimum. ‘Because CDD Vault and the ELN are so secure, we can set up user accounts for our CRO partners through which they can directly access experiments that our scientists have designed for them to carry out and report back their results and images,’ Hachisu adds.

Managing plant husbandry

While MoA Tech has demonstrated the versatility of CDD Vault for its R&D data management requirements, the company has also been innovative in its application of the CDD Vault technology. A second, separate vault has been set up by the company as a sandbox, giving scientists and new users a way of practicing with the system safely. A third vault manages MoA Tech’s plant husbandry operation supporting the three platforms: MoA Galaxy, MoA Target and MoA Select. ‘It shows the versatility of the CDD Vault infrastructure that we were able to configure a plant husbandry vault that acts as a kind of inventory for the plants themselves,’ Hachisu says.

We have even been able to set up a separate vault that we use to oversee and manage plant husbandry

‘This means we can effectively record and oversee tracking of each plant strain, to the timing and outcome of breeding and other genetic experiments, and even plant watering and disposal,’ he adds.

MoA Tech today and tomorrow

As of mid-2020, MoA Tech’s lead herbicide candidates – identified less than a year ago – were sent to its CRO partner for early field trials with results expected by the end of the year. The company projects continued growth and expansion over the next couple of years. ‘We are hoping to hire additional scientists so that, as well as continuing to progress existing compounds through R&D, we can start new discovery projects and design new compounds based on the wealth of structural and activity data already held in the Vault,’ says Hachisu.

MoA Tech hopes to further automate and augment its screening library construction, chemical target design and image phenotyping workflows by applying cutting edge artificial intelligence and machine learning tools to its system. These are currently under development in collaboration with academia and industry to select the most promising hits from the Vault for further study.

‘It’s an exciting time for MoA Tech,’ Hachisu comments. ‘CDD Vault is now an integral part of our operation, giving us a safe and secure platform for managing and accessing the vast amount of data that we generate from so many different types of experiments, without any loss of content or context. Whether it’s storing thousands of images, giving our CROs access to the data and experimental protocols that they need, or giving us an overview of all of our compounds and plants, CDD is easily configured without highly specialist IT knowledge, easy to use and has proven to be highly flexible.

For personalised demo or a free trial of CDD Vault, email info@collaborativedrug.com

References

1. S O Duke, Pestic. Sci., 2012, 68, 505-512 DOI: (10.1002/ps.2333)

2. E C Oerke, J. Agric. Sci., 2006, 144, 31-43. DOI: (10.1017/S0021859605005708)

No comments yet