A synthesis platform dubbed Allchemy has identified several drugs and agrochemicals that can be made from chemical waste streams. After predicting feasible synthetic routes, the program applies environmental, economic and geographic considerations to rank the reactions and even suggests greener alternatives to the known pathways. The software was successfully tested in an on demand drug manufacturing system.

‘By carefully limiting the extent of chemical space and ranking the synthetic routes that traverse it, this methodology allows millions of potential products to be analysed in terms of value and sustainability,’ comments Frank Glorius at the University of Münster in Germany who wasn’t involved in the study. ‘Building on such an analysis, new circular processes can be developed that save resources and reduce emissions.’

‘Historically, the emphasis has been put on making stuff, and few people have cared about what to do with all the junk left as a by-product,’ says Bartosz Grzybowski of the Polish Academy of Sciences and Ulsan National Institute of Science and Technology, South Korea, one of the creators of Allchemy. He mentions that it’s been difficult to come up with creative and economically sound ideas of the kinds of products that can be made from waste. ‘There are so many ways in which these substances can react that finding productive and useful syntheses is like searching for a needle in a haystack.’

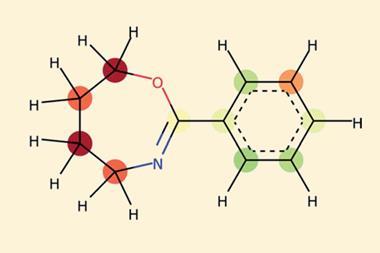

Grzybowski believes that software like Allchemy can help to address this challenge. ‘A computer can simply try all the options and finally solve a problem no human chemist would ever be able to tackle because of its sheer volume,’ he says. The computer program uses a library of chemical reaction rules that are applied to a pool of starting materials and all the resulting intermediates. In this case, the team started with 200 waste chemicals. ‘We propagated several networks – hundreds of millions of molecules each – and within a space of about a billion molecules and tens of billions of reactions, we found circular syntheses to 300 drugs,’ Grzybowski says.

‘This work is a beautiful execution of navigating the big data challenge of reaction rules, the economy of waste and chemical synthesis,’ notes Timothy Cernak from the University of Michigan in the US. ‘This work really highlighted for me that our current pollution woes are just problems in logistics, and I look forward to the co-location of pharmaceutical and fine chemical factories next to biomass and petrol waste producing plants.’

Organic synthesis planning is commonly done using a retrosynthetic approach, where a target molecule is sequentially broken into simpler precursors, but Grzybowski and colleagues have done the opposite here, points out Vikramaditya Yadav at the University of British Columbia in Canada. ‘The elegance of this work is that the researchers haven’t necessarily invented a new way to convert waste into medicines. They’ve merely shifted the focus from product to feedstock.’

Robert Paton from Colorado State University and the NSF Center for Computer-Assisted Synthesis, US, explains that Allchemy can automatically filter routes with undesirable reaction conditions, harmful reagents, problematic solvents or low atom economy. ‘It even assesses geographical proximity to bulk starting materials,’ he says. ‘Coupled with emerging methods in de novo molecule design, the approach could helpfully restrict chemists’ attention only to those molecular targets with a viable synthesis from abundant precursors.’

‘An important feature is that we evaluate reactions not only for lab-scale feasibility but also for process feasibility,’ notes Grzybowski. ‘This is key because if we aim for circular chemistry, we need to find routes that aren’t going to ruin the environment.’

The team validated several of the reactions experimentally. ‘We made a [World Health Organization]-essential anti-leprosy drug from degraded plastic bottles [lactic acid] and phenol, a by-product of coal processing,’ Grzybowski says. ’We also made some heart medications and – above all – with the help of our colleagues at On Demand Pharmaceuticals, we implemented manufacturing of some drugs important for the Covid pandemic.’ They weren’t drugs that target Sars-CoV-2, he adds, just other medicines that hospitals use to manage patients with severe Covid.

But programs like Allchemy can only develop their full potential if they’re adopted and shared across the chemical industry, points out Grzybowski. ‘What I envision is a system in which companies deposit info about the waste they wish to dispose, then Allchemy calculates what useful stuff can be made from it and how, and some other companies bid for to actually take this waste and run the synthesis.’

References

A Wołos et al, Nature, 2022, 604, 668 (DOI: 10.1038/s41586-022-04503-9)

No comments yet