Keeping cool in summer can be hard work. But scientists in the US have created a nanoporous textile that they claim will help as it allows body heat to escape, while reflecting sunlight.

Staying cool can be pricey as air conditioners are energy hogs with large carbon footprints. In the US, air conditioning accounts for 5% of annual electricity consumption, with $11 billion (£8.3 billion) spent every year on cooling units and maintenance.

‘Indoor spacing heating and cooling is a major part of energy consumption around the world,’ says Yi Cui from Stanford University. ‘We would like to find a way to better cool off the human body so we can save the energy of air conditioning.’

A cheaper way to cool down is by wearing thin cotton shirts or linen, but the materials end up soaking up sweat and stopping infrared body heat from escaping. IR radiation accounts for up to 50% of body heat loss, so if scientists can design a textile that is transparent to it, the public can wear a garment that cools them down during those heady summer days.

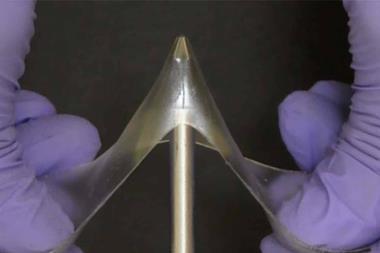

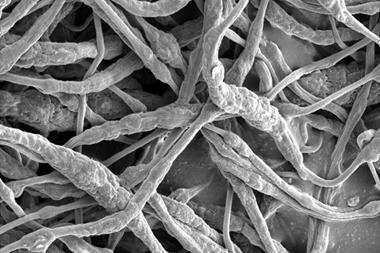

Cui and his colleagues have now found such a material, albeit from an unlikely source. The team noticed that the polyethylene separator (nanoPE) used in lithium–ion batteries has an interconnected series of nanopores that resemble a fibrous textile.

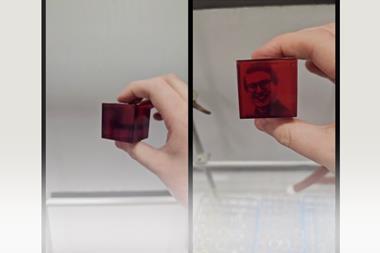

To test whether the nanoPE material was transparent to body IR radiation, Cui’s group laid it on top of a heating element and an H-shaped metal wire. At IR wavelengths simulating emissions from human skin, the H is visible through the nanoPE layer. When the team placed cotton over the device, the H disappeared – suggesting cotton stops body heat from escaping.

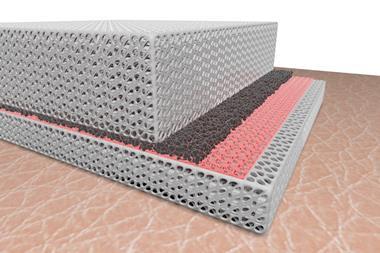

The nanoPE transmits over 90% of a body’s total IR heat – cotton only transmits around 1.5% – and the nanopore size is what determines its cooling effect. The pores, which are around 50–1000nm in diameter, are much smaller than the IR wavelengths radiated and so are transparent to it. But they are of comparable size to visible light wavelengths, and so can scatter and reflect incoming sunlight.

Recognising the nanoPE material is not a conventional weaved textile, the team also produced a nanoPE–cotton mesh composite. ‘The pristine nanoPE is 2.7°C cooler than cotton, and the processed tri-layer nanoPE–mesh is 2°C cooler than cotton,’ explains Cui. The material can also transport sweat and allow air in through the pores.

But Cui is aware that the team will need to produce a fully-woven textile before it can be used commercially. ‘Currently our nanoPE is still a non-woven structure, but we generally enjoy wearing woven textile more,’ he says. ‘We are developing a woven nanoPE which will be closer to a traditional textile.’

‘Regarding the potential of nanoPE as a new textile material, clearly there is still much to be done,’ says YuHuang Wang, a chemist from the University of Maryland, US, with a keen interest in cooling textiles. ‘But the observation made by Cui and co-workers can be the foundational first step to a new energy-saving technology.’

References

P–C Hsu et al, Science, 2016, DOI: 10.1126/science.aaf5471

No comments yet