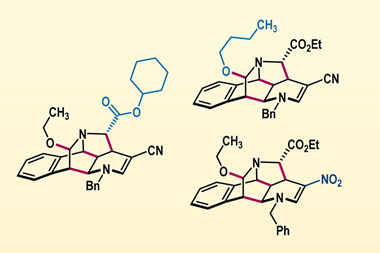

Filter paper can serve as a reaction platform for synthesising compounds that are useful structural templates for medicinal and organic chemistry called squaramides. The new approach is more sustainable than traditional synthesis methods and achieves reaction yields of up to 99.5%.

Squaramides have a four-membered carbon ring with amine groups connected to two of the ring’s corners and carbonyl oxygens connected to the other two. As bioisosteres of various functional groups, they interrogate the hydrogen bonding potential in biological targets and influence molecular conformations in drug ligands. These abilities are valuable to chemists developing more potent and selective drug candidates.

Current methods for synthesising squaramides face limitations, such as using high-boiling-point solvents, and having long reaction times, ineffective or lengthy purification steps and high operating temperatures.

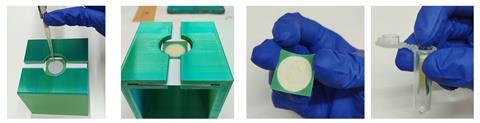

Previous research has shown that paper can support catalysts or be used to filter catalysts from reaction products. Now, Margherita Brindisi and colleagues at the University of Naples Federico II in Italy have taken this one step further by using filter paper as a platform for synthesising 36 squaramide-based compounds with an eco-friendly solvent system.

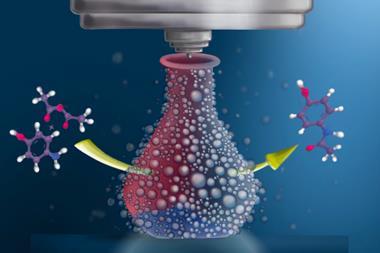

A 3D-printed structure holds the paper during the entire process. Dimethyl squarate dissolved in ethanol and water is added to the paper before the amine is added dropwise. Capillary-driven flow through the filter paper ensures uniform reagent distribution, and continuous solvent evaporation shifts the reaction equilibria towards product formation. Small-scale tests with benzylamine at room temperature gave a yield of 97% after five minutes.

‘The adoption of a paper-based platform allows the reaction to proceed without the complication of water removal and avoids the need for complex equipment or time-consuming purification steps,’ explains Brindisi. ‘A potential limitation is the use of water-based solvents, which may not suit all compounds. However, this can be further optimised through ongoing investigation.’

‘Our paper-based synthesis method is designed for scalability. By increasing the filter disc’s diameter, the process can be seamlessly adapted from lab to larger-scale production. This makes it a robust and programmable platform for scale-up,’ says Brindisi.

‘I have calculated that, for a lab-scale synthesis say with 6g of the cyclobutenedione, the diameter of the filter paper would be about 54cm. That is quite possible to scale-up,’ comments Jean Lessard, a physical organic chemist from Sherbrooke University in Canada. ‘On the industrial level, say on a few hundred grams of the cyclobutenedione, it becomes an engineering problem. To me, it is difficult to imagine how this could be done. However, as a consultant for a pharmaceutical company, I have seen how the process chemists and engineers are good at finding solutions to scale-up problems.’

Brindisi suggests that filter paper could be used to synthesise other organic compounds as long as the starting materials are soluble in a water-based solvent. ‘Each reaction setup has its own challenges, which should be evaluated case by case. In general, this approach represents a promising starting point that could be exploited for further applications in chemical synthesis.’

References

A I Alfano et al, Green Chem., 2025, DOI: 10.1039/d5gc00535c

No comments yet