A process that combines heat and UV exposure has shown it’s possible to turn wheat gluten into a vegan leather that is flexible, water resistant and almost matches the strength of animal leather without using synthetic polymers or chemical crosslinkers.1 The physical treatments reorganise gluten’s native protein network, creating bonds that give the material its enhanced properties.

The global leather goods industry was valued at over $500 billion (£370 billion) in 2025 and is expected to keep growing over the next decade. Yet concerns over the environmental impact and animal welfare issues associated with conventional leather have intensified efforts to develop greener, more ethical alternatives. However, most bio‑based leather substitutes struggle to replicate natural leather’s mechanical properties under wet and dry conditions and those that do rely on chemical crosslinkers and water-repellent coatings.

Now, a team led by Dongyeop Oh from Korea University in South Korea has developed a new approach to preparing gluten-based vegan leather. ‘It’s really like making bread,’ jokes team member Soyeon Kim. ‘We add water and glycerol to gluten and mould it into a film. Gluten consists of 2–3% of cysteine residues and an [initial] mild thermal treatment induces the oxidation of these cysteine residues to form disulfide bonds, leading to the formation of a 3D gluten network, which is both durable and flexible. [Then], high temperature heating and an ultraviolet treatment promotes the formation of new covalent compounds like cysteinyl–DOPA [dihydroxyphenylalanine], which enhance the water resistance of the gluten leather.’

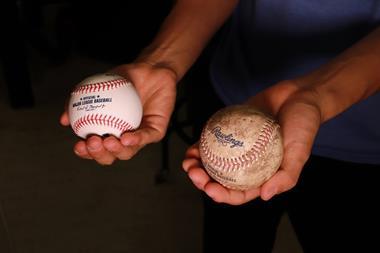

The resulting material demonstrated a tensile strength of 10–14MPa and a toughness of 4.6MJ m-3, in contrast to the 0.4–1.75MPa tensile strength of previous solvent-cast, gluten-based materials.2 ‘Previous gluten films have used strong bases to hydrolyse the gluten, which prevented the formation of gluten networks,’ explains Kim. Moreover, subsequent tanning with tannic acid and iron chloride produced a gluten leather with a tensile strength of 17.2MPa, comparing favourably to animal-based leather’s tensile strength of 17.9MPa.

However, large-scale production of these materials is unlikely to be straightforward. ‘These bio-based materials have to be processed at high water and plasticiser (glycerol) content,’ comments Michael Meyer, an expert in biopolymers from the FILK Freiberg Institute in Germany. ‘[This] water must be dried out during production and the plasticiser must not bleed out after use. [Additionally], the researchers have used expensive, pure gluten, whereas industrial quality gluten may contain residual starch which may lead to discolouration due to the Maillard reaction.’

Oh, Kim, and co-workers are aware of these challenges. ‘Gluten is a naturally-derived protein and so we need to standardise the process to ensure its reproducibility,’ adds Kim. ‘We also need to scale up the production and control the material’s biodegradation. Thankfully, there’s been increasing interest in vegan leather in the fashion industry and so I’d like to commercialise gluten leather if we have the opportunity to.’

References

1 S Kim et al, Mater. Horiz., 2026,13, 233 (DOI: 10.1039/d5mh01579k)

2 M Dong et al, LWT, 2022, 154, (DOI: 10.1016/j.lwt.2021.112868)

No comments yet