Varying the position of a reaction vessel on a magnetic stirrer can significantly change the outcome of a chemical reaction. That’s the conclusion of scientists working with Valentine Ananikov from the Russian Academy of Sciences, who made this discovery while running the same reaction in parallel in different vials placed side-by-side on the same stirrer. ‘We found that reaction speed, product quality and even the formation of nanoparticles changed depending on the vessel’s location,’ explains Ananikov. ‘In some cases, the differences were large enough to explain why another lab might fail to reproduce the results.’ To solve this problem, the team recommends running control experiments in what they call the ‘green zone’ of the stirrer, where stirring is most stable and efficient.

‘Many chemists rely on magnetic stirrers every day, assuming that they work uniformly across their surface, but our experiments revealed a somewhat surprising picture,’ says Ananikov. He and his colleagues observed that the nature of the bar rotation changed when it was placed at different positions on and above the stirrer, stopping completely at some locations. The new results are not only important for chemistry but also for areas like biology, life sciences and material sciences.

Ananikov and his team warned in 2019 that ‘dirty’ stirrer bars contaminated with minute quantities of metal could be responsible for the unexpected reactivity reported in some experiments.

Valentine Ananikov has prepared advice on how to check if your stirrers are affecting your results and to fix any problems.

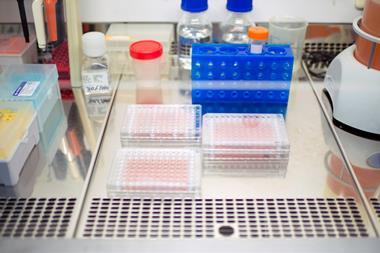

The researchers analysed several types of reactions using magnetic stirrers from different manufacturers. The experimental setup was quite simple: they used cameras to record colour variations and carried out NMR spectroscopy and electron microscopy studies to detect chemical changes and look at the products in detail.

One of the processes they studied was the formation of palladium particles in solution. ‘We found that, depending on where the vial sat on the magnetic stirrer, the particles formed at different rates and had different sizes, even though everything else was kept exactly the same,’ says Ananikov.

The team also looked at the preparation of palladium-on-carbon catalysts, which are widely used in organic synthesis. ‘Again, the location of the vial on the stirrer caused differences in how fast the catalyst formed and what the final structure looked like,’ explains Ananikov. In some vials, the carbon support was even physically damaged by the stirrer bar, changing the shape of the catalyst, he adds.

In another test, the researchers scrutinised the Suzuki–Miyaura cross-coupling reaction, which plays an important role in the production of drugs and agrochemicals. They noticed that the same reaction mixture gave very different product yields depending on its position on the stirrer. ‘We saw conversion differences of about 10 to 20%, and in some cases even more,’ says Ananikov. ‘That’s enough to make a successful experiment seem like a poorly reproducible failure in another lab.’ The scientists also tested processes like polymerisation or the Belousov–Zhabotinsky reaction – famous for its oscillating, colour-changing patterns – and in all cases, the reproducibility of the results was affected by stirring inconsistencies.

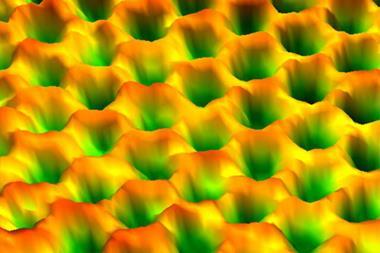

Based on their results, the team introduced a simple procedure to map magnetic fields – using a metallic powder – and estimated the most efficient and stable stirring positions on the plate. ‘For any important experiment, we strongly recommend doing a control run with a single vial placed in this “green zone”,’ suggests Ananikov. He also recommends reporting the type of stirrer, the stir bar, and the type and size of the reaction vessel in the experimental section. ‘Manufacturers could also help by marking the most efficient stirring zones on their devices, so researchers can see where to place their reactions for best performance,’ he adds.

Rick Danheiser from the Massachusetts Institute of Technology in the US, who wasn’t involved in the study, recognises that experienced synthetic chemists have long been aware that the way in which reaction mixtures are stirred can impact the results of chemical processes. ‘Ananikov and co-workers now describe an impressive systematic study of the effect of the positioning of reaction vials on magnetic stirrers on the outcome of several heterogeneous reactions,’ he says. ‘Their work will serve to encourage researchers to pay closer attention to this experimental variable and to take care to describe, in more detail, the type of stirring when reporting experimental procedures in publications.’

References

VA Cherepanova et al, JACS Au, 2025, DOI: 10.1021/jacsau.5c00412

No comments yet