Incorporating nanoparticles of carbon black into wet cement can transform it into a supercapacitor electrode once the cement has cured, US researchers have shown. The team says that the material could be used to store renewable energy and find more exotic applications such as roads that can wirelessly charge electric vehicles.

Production of cement and concrete is today responsible for approximately 8% of global carbon dioxide emissions. Several ideas to reduce this by using alternative cement formulations, for example, have yet to achieve widespread success. Meanwhile, rising investment in intermittent renewable energy sources has led to rising demand for storage technologies. ‘Batteries are based on rare materials that are not available to everyone, so it’s not scalable,’ says Franz-Josef Ulm of the Massachusetts Institute of Technology. Ulm and colleagues devised a bipartite solution by adding new functionality to concrete, allowing it to be used as a ‘structural capacitor’.

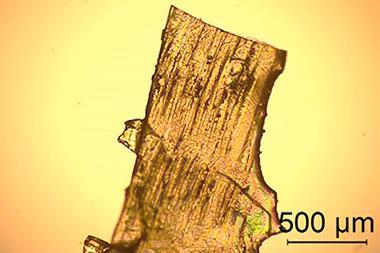

The researchers simply add nanoparticles of carbon black to cement paste. Being hydrophobic, these initially stay isolated in the water-rich environment. As the cement cures, however, the hydrophilic calcium silicates form calcium silicate hydrates and calcium hydroxide, removing free water from the system. The carbon nanoparticles then self-organise into an extremely long conductive network permeating the cement. By soaking the cement in potassium hydroxide, the researchers allow ions to diffuse in and out of the pores. Connecting the electrode to a positive charge causes the conductive network to attract negative ions and repel positive ions and the reverse when it is connected to a negative charge. Separating two of these saturated cement slabs by a dielectric membrane therefore allows a potential difference to build up and energy to be stored.

The researchers used small charged cement supercapacitors to power a 3V LED, and now hope to move to large-scale, real-world applications. The charge/discharge rate is limited by the porosity of the cement, but this shouldn’t be a problem in building foundations that can store solar energy, for example. ‘You have the whole day to charge the supercapacitors and then overnight…you use it to run whatever type of energy load you need for the home,’ Ulm says.

The researchers showed that they could also increase the porosity of the cured cement by adding extra water during its production. This allows for faster charge/discharge cycling, which could open up applications such as roads that charge passing electric vehicles by electromagnetic induction, although it does compromise the strength of the concrete. ‘For each application there will be different requirements we need to fulfil,’ says co-author Admir Masic. ‘The essential point our paper is making is the accessibility of our material anywhere in the world for everyone. I honestly expect this material to permeate our society in an unprecedented manner simply because it is two inexpensive materials that we know how to process.’

Deborah Chung at the University of Buffalo, the State University of New York, is skeptical, however. ‘In the abstract they claim high strength, but in the paper there is no measurement of the strength,’ she says. The researchers rely on hardness measurements from nano-identation, and Ulm says he has ‘built a career showing the link between hardness and strength’ but Chung remains unconvinced and says that this ‘is not an adequately recognised mechanical property indicator in the concrete field’. ‘The high porosity is bound to cause fragility… I’m positive that the material that they are calling a structural electrode is actually a fragile material,’ she concludes.

Bernhard Pichler at Vienna University of Technology in Austria, however, does not dispute the strength measurements, and says that ‘the authors have used an initial water-to-cement mass ratio of 0.42. This allows you to produce regular-strength concrete. In many practical applications, even larger ratios are used… Lower ratios are needed to produce ultra-high performance concretes, but they are used for rather special applications only. Overall, I think this paper is extremely interesting, and it will be influential in my scientific community for sure.’

References

N Chanut et al, Proc. Natl. Acad. Sci. USA, 2023, 120, e2304318120 (DOI: 10.1073/pnas.2304318120)

No comments yet