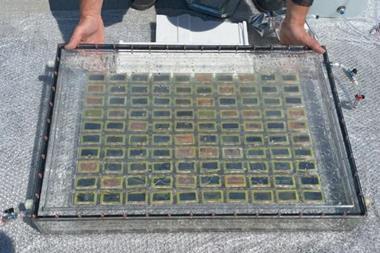

Last year, Oxford PV installed the first commercial solar panels to incorporate perovskites at a solar farm in the US. Perovskite materials have long been hailed as a technology capable of delivering cheap renewable energy on a global scale and many researchers believe their power conversion efficiencies can climb higher in the years ahead.

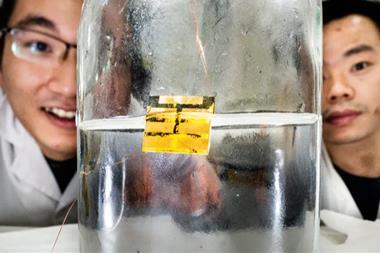

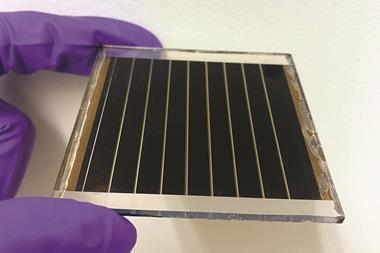

As James Mitchell Crow reported in this recent feature, kesterite – another mineral-inspired material – is also attracting researchers’ interest in this space. Made from copper, zinc and tin combined with sulfur, selenium or a mixture of the two, kesterite is re-emerging after years of stagnation as a promising light absorber for thin-film solar cells. Like perovskites, kesterite’s bandgap and other electronic properties can be tuned by adjusting its composition, but it offers the advantages of being both free from rare or toxic elements and highly stable. However, as Mitchell Crow’s feature highlights, kesterite’s benefits must also be considered in the context of the solvents required in its production.

Solvents play a critical role in creating high-quality thin-film materials. The evaporation rate of a solvent influences how crystals nucleate and grow, shaping film uniformity, defect density and coverage. Solvents must dissolve all constituent elements or precursors yet also evaporate cleanly, leaving no impurities that would compromise device performance.

Dimethylformamide and hydrazine respectively produce excellent perovskite and kesterite films, but they are also toxic and volatile with high disposal costs. Industrial-scale operations spend significant sums of money handling solvent waste. More concerning, however, are the risks that some solvents pose to workers’ health and to the environment.

Researchers are exploring greener alternatives such as gamma-valerolactone and ethanol. These solvents promise better safety profiles and, in some cases, lower costs. But they are not drop-in replacements. Many introduce new challenges, from limited solubility of precursors to incompatible evaporation dynamics. In practice, switching solvents can alter how crystals form and, in turn, how well the resulting solar cells perform.

It’s encouraging to see researchers confronting this challenge and recognising that the future of solar innovation depends not only on the materials themselves but also on the chemistry that makes them possible. Keeping solvents at the centre of the conversation is vital to ensure these devices don’t undermine the very sustainability they are supposed to deliver.

No comments yet