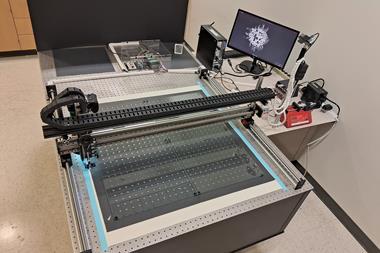

A touchpad that allows users to move and manipulate individual droplets in a microfluidic device has been developed by researchers in China. The technology works much like a phone touchscreen and adds a heightened level of control and interactivity to the emerging field of digital microfluidics.

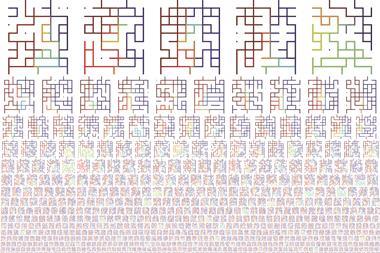

Microfluidics offers a way of doing experiments that consumes minimal amounts of reagents. Digital microfluidics uses electrical signals from an array of electrodes to control the shape and positions of droplets on a surface so can forego the need for microcompoents, such as micropipes, micropumps, microvalves and micromixers.

A wide range of reactions can be carried out in microfluidic devices. In particular, the technology is often used in cell-free biology, where experiments are conducted in vitro imitating conditions found in vivo. One limitation is that users have to rely on pre-set programs to control how the droplets move.

Motivated by wanting to simplify the liquid handling processes currently used to carry out cell-free biology, researchers at Tsinghua University, led by Yuan Lu, have designed an interface for single-drop cell-free biological reactions. The droplet–user interface allows for real-time interactions between the droplet and the operator via a touchpad. Fingertip motions on the touchpad tell a control program when to turn on electrodes in the microfluidic device, and results in droplet movements that mimic the fingertip motions. The system is currently limited to a small electrode array and cannot be applied to large-scale droplets.

Steve Shih, an expert in automated microfluidics at Concordia University in Canada, says the touchpad can help overcome two bottlenecks in synthetic biology: a lack of automation and the laborious processes involved with genetically encoding cells. The work ‘can breakthrough these challenges, to standardise biology and is a remarkable step forward to being the assembly line in the process of synthetic biology.’

Team member Dong Liu says scaling up traditional research techniques wastes labour and disposable consumables. ‘The operation simply to remove the droplets occupies 50% of the experimental time, while one-off consumables like tubes and pipette tips occupy a significant part of research funds. Using the nearly zero-consumable digital microfluidics for the liquid process would benefit the environment and build greener research operations,’ he says. The team plan to develop the work further to create a smart and sustainable cell-free biology reaction platform.

References

This article is open access

D Liu et al, RSC Adv., 2020, 10, 26972 (DOI: 10.1039/d0ra04588h)

No comments yet