The news of severe bacterial contamination in Argentinian fentanyl supplies certainly illustrates some tragic issues with quality control. A manufacturing facility can face stiff fines, loss of business, and even criminal prosecution for such mistakes, and that’s certainly what we’ll be seeing here. But many readers will probably have been surprised to learn that there is such a thing as an above-board fentanyl production site in Argentina to start with.

This takes us into the world of generic drugs, which (full disclosure) is not a part of the business that I’ve ever worked in myself. I’ve spent my career in the discovery end of pharma, doing work that is supposed to lead to new, patent-protected medicines. Such drugs are owned by their developers (or anyone to whom they have legally assigned the rights), and these patent owners tend to defend their rights vigorously. There is little competition on price, since there is really only one source: the price is what each individual market will bear.

But all patents expire, and when they do, a huge shift in gears takes place. Generic drug manufacturers step in, and they most certainly do compete on price (and on any other advantage that they can find). At first, there may be one or two generic firms that have agreed to work with the original developer for a handoff of the drug (generally as part of an agreement not to challenge the original patents even earlier than their expiry dates!) But over time, an older drug’s manufacture and supply becomes something of a free-for-all.

If you have some sort of drug manufacturing facility and think that there might be a market for a new supplier of a given medication, you can try your hand at it. The chemical routes to the drug substance will be generally pretty well known by this point, although some of the larger generic manufacturers certainly continue to try to improve the synthetic routes. By ‘improve’, one generally means ‘make them even cheaper’, and many of these modifications can end up being held as trade secrets rather than as patents. That means you don’t have to disclose them (as you would in a patent application) but it also means that you have little recourse if someone else figures out your tricks.

There is nothing more opportunistic than freelance bacteria. Ignore them at your peril

So why make fentanyl in Argentina? It is, of course, a widely used pain medication, so there is certainly a legal market. In many countries, a local supplier might have an advantage due to tariffs or other legal barriers to foreign competition, or they might have a better logistical position to supply the market around them. You can also end up (as happens in many industries) with a situation where a small company can make a living off a niche market that larger players don’t necessarily find worthwhile bothering with, because they feel that their capital can be put to better use elsewhere.

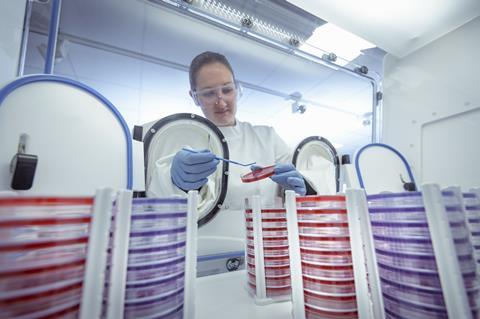

You hear the phrase ‘economies of scale’ quite a bit regarding manufacturing, though, and for good reason. There are things that every drug manufacturer has to deal with (batch-to-batch variability, purity, packaging and distribution, regulatory paperwork) that may well be easier for a larger operation to handle. In the US, there was a similarly terrible contamination story in 2012 at the New England Compounding Center in Massachusetts, whose laxity in preparing injectable drugs killed dozens of people via fungal meningitis infection. My impression is that the great majority of these incidents trace back to small facilities whose staff don’t realise the problems until far too late, and it’s clear that this was far from the Argentine company’s first brush with bacterial contamination problems.

It might seem strange to have toxic bacteria growing in fentanyl samples, since the drug has a fearsome reputation for toxicity. But keep in mind that bacteria don’t even have opioid receptors (or any other G-protein-coupled receptor proteins), since those are a feature of multicellular life. My guess is that the bacteria were using other parts of the fentanyl formulations as food, that is, the buffers, stabilisers and salts that almost all injectable drugs include to prolong shelf life and improve compatibility with the tissues they’re injected into. Similarly, the fillers, binders and other ingredients that would go into drug tablets can be a buffet for contaminant microbes. There is nothing more opportunistic than freelance bacteria, and as this story shows, you ignore them at your peril. And at the peril of your customers.

No comments yet