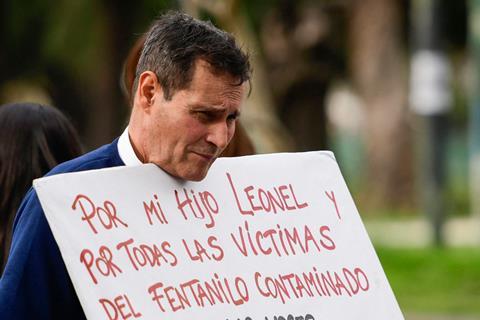

A drug contamination tragedy in Argentina has seen medical fentanyl killing patients by causing microbial infections. The official death toll sits at 51, although authorities suspect up to 100 deaths could be associated with the tainted drug.

Microbial contamination of drug batches is, unfortunately, a persistent issue. Even the most stringently run facilities can be susceptible to accidental contamination. Fortunately, most such incidents are intercepted either by internal quality control or routine regulatory checks before any harm is inflicted on patients. But when those safeguards fail, the consequences are severe.

Unlike some cases of chemical adulteration – such as in the glycol-contaminated cough syrups that killed hundreds of children in The Gambia, Indonesia and Uzbekistan in 2022–23 – microbial contamination is rarely deliberate. Mostly it stems from lapses in hygiene protocols, or use of substandard ingredients.

Decisions made by drugmakers can, however, make contamination more or less likely. And with huge pressure on manufacturers to keep generic drug prices low, there is a temptation to trade off rigorous hygiene and quality assurance against speed and productivity. Cheaper methods of detecting contamination – such as cell-culture or enzyme-based assays – are slow, and can miss microbes that don’t grow easily in the lab. And while faster, more comprehensive testing protocols are available using mass spectrometry, Raman spectrometry or DNA detection via PCR, they are significantly more expensive.

The microbes are also getting tougher to kill. Widespread use of biocides contributes to the growing threat of antimicrobial resistance. Cleaning procedures that were previously effective may no longer be sufficient to eradicate the most stubbornly resistant microbes. Those microbes are also more likely to cause infections that resist treatment with existing drugs, making early detection of contamination even more important.

None of these factors relieve Argentina’s HLB Pharma (or any other drugmaker) of its responsibility to adhere to quality and hygiene standards – investigations suggest persistent quality deficiencies at the company and its laboratory partner. Nor do they excuse the seemingly lenient enforcement actions by Argentina’s regulator, ANMAT. But they add to the growing strain on supply chains for generic drugs, which already operate on thin profit margins. Extreme competition on prices undermines investment in quality assurance or maintaining, renewing and upgrading aging equipment. As long as that continues, it’s likely drug shortages and related quality issues such as contamination will persist or even increase.

No comments yet