Scientists in Germany have created an alloy with an exceptionally low corrosion rate – lower, even, than ultra high-purity magnesium – that they say approaches stainless magnesium, by alloying pure magnesium with tiny amounts of calcium.

Due to its low weight, high strength, abundance in the Earth’s crust and excellent electrochemical properties, magnesium is widely used in automotive, aerospace, electronic, biomedical and energy-storage applications. In particular, magnesium’s weight makes it attractive from a sustainable perspective – it is significantly lighter than aluminium, so replacing aluminium with stainless magnesium in cars and aeroplanes could reduce fuel consumption and carbon dioxide emissions. However, using magnesium on an industrial scale is limited because it corrodes in aqueous environments.

‘Our magnesium–calcium alloys were prepared by conventional casting processes,’ explains Min Deng from the Helmholtz Centre for Materials and Coastal Research in Geesthacht. ‘Pure magnesium and pure calcium were melted at high temperatures in a steel crucible. Then, the melt was poured into a steel mould. After cooling to room temperature, the alloys were ready for use.’

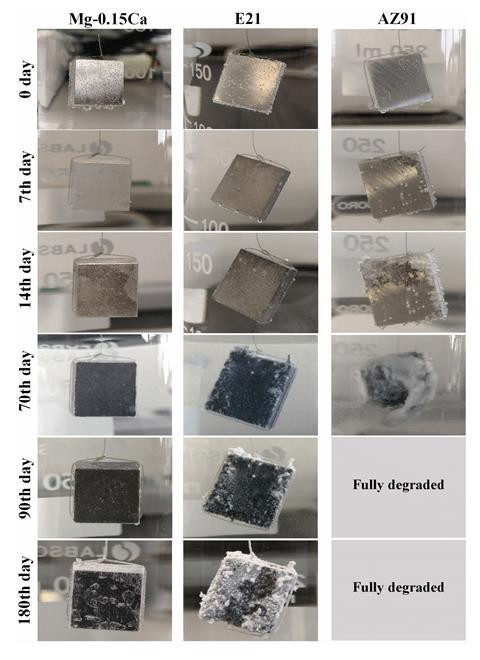

By using only tiny amounts of calcium, the new alloy retains the properties of pure magnesium. However, it can resist corrosion because the calcium reduces the cathodic water reduction kinetics, allows the development of a protective surface film and stabilises impurities (such as iron and silicon) within the alloy.

Coating or alloying magnesium with elements such as lithium, aluminium or arsenic, is a common way to hold back corrosion. ‘Compared to existing alloying [compositions], the addition of calcium broadens the practical applications of magnesium alloys an implant material, since calcium is harmless to the human body. Previous attempts to develop high corrosion-resistant magnesium alloys have always involved delicate and complicated processes,’ explains Linqian Wang, another member of the Helmholtz team. ‘In comparison, the processing route for [our] magnesium–calcium alloy with [its] superior performance is quite simple, eco-efficient and economical.’

The alloy could have ‘biomedical applications, such as scaffolds and implants, because it seems to reduce significantly the formation of hydrogen bubbles, [which are] common in existing magnesium implant materials, [and] the formed corrosion products are not expected to be toxic,’ comments Polina Volovitch, who studies corrosion at Chimie ParisTech in France. ‘Application in aqueous batteries could also be [possible].’

‘Practical applications of stainless magnesium are many and varied. Certainly portable electronics come to mind, but as a wonder material, the world is magnesium’s oyster,’ adds Nick Birbilis, who specialises in material sustainability and corrosion science at the Australian National University. ‘Steel came before skyscrapers, so let’s see what magnesium will bring us.’

References

This article is free to access until 12 April 2021

M Deng et al, Mater. Horiz., 2021, 8, 589 (DOI: 10.1039/d0mh01380c)

2 readers' comments