A new method for programming intricate shape changes in liquid crystal elastomers could enable new advances in soft robotics, biomedical devices and 3D printing.

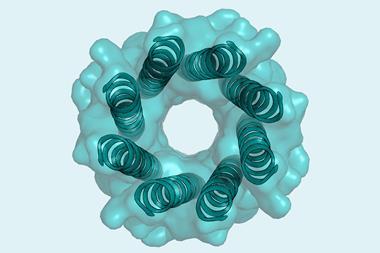

Liquid crystal elastomers have a crosslinked structure made of overlapping liquid crystal polymer networks. Like elastomers, they are stretchy and malleable, and they can self-organise like the liquid crystals in flat screen television displays. They change shape in response to stimuli such as heat, UV light or electric fields, and recently, they have been in the spotlight as candidates for artificial muscles in robots.

Now, Morgan Barnes and Rafael Verduzco of Rice University have devised a new way to program reversible and complex 3D shapes into liquid crystal elastomers via a two-step, double networking crosslinking reaction.

In the first step, three polymers combine in a solvent to make a liquid crystal elastomer. In the second step, the liquid crystal elastomer is mechanically sculpted into a desired shape and UV-cured by exposure to UV light. Heating causes the liquid crystal elastomer to lose its 3D structure – but when cooled, the liquid crystal elastomer remembers its shape and the 3D structure reforms. By heating and cooling the material, the liquid crystal elastomer can morph between flat and complex 3D shapes on demand.

Shape-morphing materials like this are more than just a curiosity – they could be used to make topological pixels for braille displays, programmable 3D displays for advanced computing or microfluidic devices for chemical reactions on the microscale.

References

M Barnes and R Verduzco, Soft Matter, 2019, DOI: 10.1039/c8sm02174k

No comments yet