The first nanomachines that can be switched into reverse gear using only light have been created.1 Embedded into a piece of polymer gel the tiny machinery can be used to shrink and expand the material.

Nanomachines can already perform functions such as assembling molecules, but many molecular motors only work in one direction. Ben Feringa’s team was the first to develop nanorotors with a reverse gear, but the system requires temperature changes and different chemicals to switch direction.

Moreover, as Nathalie Katsonis, biomolecular nanotechnology researcher at the University of Twente in the Netherlands, who wasn’t involved in the new research, explains: ‘You can have molecular motors in solution and demonstrate that they rotate in one or the other direction, but you’ll never be able to do anything with this rotation unless the machine is coupled to a supramolecular or macromolecular system.’

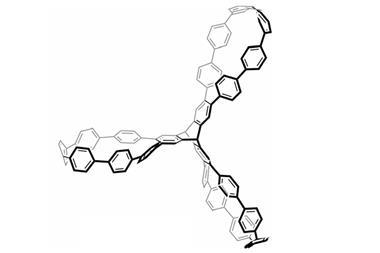

Now, Nicolas Giuseppone and his team from the University of Strasbourg in France have done just that: they created light-controlled nanosized machinery and attached it to polymer chains. Using light of different wavelengths, the researchers can expand or contract a centimetre-sized piece of polymer gel the nanomotors are embedded in.

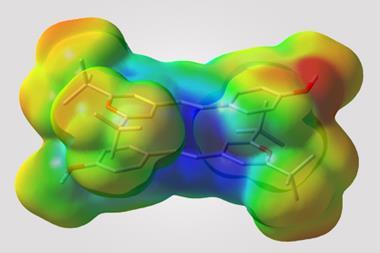

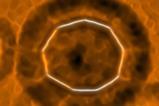

Giuseppone’s system contains two parts, a ratchet and a modulator. Under UV light, the ratchet – a sterically crowded alkene – turns and winds the polymer chains it is attached to around each other, shortening them and shrinking the polymer.2 At the same time, the modulator – a dithienylethene photoswitch – is in its cyclised, locked form, and sustains the polymer chains’ tension the motor creates. Switching to visible light, the ratchet stops turning, but the modulator forms an open chain and becomes unlocked. It then ‘turns by releasing the elastic energy stored in the braided polymer chains as kinetic energy’, Giuseppone explains.

Katsonis thinks that Giuseppone’s work addresses some of the fundamental challenges molecular machines face. ‘If we want to go towards mechanised molecular matter we need to be able bring machines back to their initial state so they can produce work again and again.’

While the macroscopic movement is currently quite slow – it takes the modulators several hours to ‘unwind’ a piece of fully contracted gel – Giuseppone’s team is working on making this process faster. Eventually, motor materials could be used as artificial muscles or be incorporated in macroscopic machines that move fuelled only by light without requiring any classical mechanical parts.

References

1 J T Foy et al, Nat. Nanotechnol., 2017, DOI: 10.1038/nnano.2017.28

2 Q Li et al, Nat. Nanotechnol., 2015, 10, 161 (DOI: 10.1038/nnano.2014.315)

No comments yet