With many common brominated flame retardants facing bans, Nuala Moran examines the industry’s dash to make – and test – new ones

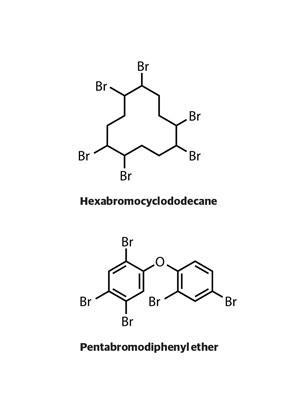

The decision in May this year to move towards a global ban on the production and use of hexabromocyclododecane (HBCD, also referred to as HBCDD) once again highlighted the long-running concerns about the toxicity of some brominated flame retardants and the need to find low-cost and effective alternatives.

This follows earlier agreements in 2009 to eliminate tetrabromodiphenyl ether and pentabromodiphenyl ether, in the face of evidence that they bioaccumulate in aquatic and terrestrial food chains, human tissues and breast milk, and can have serious toxicological effects, such as endocrine disruption.

These multilateral agreements under the Stockholm Convention on Persistent Organic Pollutants followed previous bans in the US and Europe of other brominated fire retardants in 2004. Each of these bans followed long years of lobbying, providing time for industry and researchers to come up with substitutes. But although there are numerous other flame retardants with a range of different chemistries, there is one significant problem to be overcome: the amount of alternative additive that is needed to be effective is greater than the level required with brominated flame retardants.

This has implications for the cost, manufacturing and also the properties of the polymer materials to which flame retardants are added. There are other issues too: while the spotlight has been on halogenated flame retardants in general and brominated flame retardants in particular, investigation of the health and environmental impact of the alternatives is incomplete.

Bans on brominated products that are acknowledged to be effective in improving safety are being brought in at a time of rising fire protection standards and increasing use of flammable polymers and polymer composites in homes, offices and transport. This is prompting a rise in demand for fire retardants and underlining the need to find substitutes. Worldwide sales of flame retardants currently stand at $4 billion (£2.6 billion) per annum and according to the market research company Ceresana of Vienna, Austria, the global market will grow to $5.8 billion by 2018.

Bromine is best

HBCD is the mainstay in flame-proofing both the extruded and expanded polystyrene foam that is widely used in insulating buildings to reduce their carbon footprint, so finding an alternative for it is pressing. Inken Beulich is European Union R&D director at Dow, a major producer of building foam, and says the pressure has been growing for more than a decade. ‘We saw the regulatory pressure coming on brominated small molecules and set up a research programme in 2004 to look at alternative, more sustainable solutions,’ she says.

Bromine really is the best fire retardant for polystyrene

Inken Beulich

There are three mechanisms by which flame retardants can exert their effects: in the gas phase by inhibiting exothermic oxidation in the flame by scavenging hydrogen radicals; cooling the reaction down by absorbing heat and releasing water vapour; or by cross-linking the radicals produced when polymer chains are broken down, thus forming thermally stable polymers, or char, that act as a thermal barrier.

The difficulty with polystyrene foam is that it is full of air, meaning it is difficult to suppress burning other than in the gas phase – which is how halogenated flame retardants work. Dow spent time investigating possible alternatives before concluding that ‘bromine really is the best fire retardant for polystyrene’, Beulich says.

This finding led to the development of a polymeric form of bromine that retains the fire retardant properties of its small molecule counterpart, but is too large a molecule to pass through cell walls and accumulate. Beulich says studies carried out by Dow show it is stable and non-toxic. The question of how easy it will be to recycle remains open for now, since the supplies that are starting to come on stream are likely to remain in buildings for 20?years at least.

Dow Building Solutions, the Dow unit which manufactures polystyrene foam, has started preparations to convert its plants to use the polymeric brominated flame retardant. In addition, Dow has licensed the technology to three other manufacturers, Great Lakes Solutions (part of Chemtura), Albemarle and ICL Industrial Products. Earlier this year all three announced they are ready to supply polystyrene protected with the polymeric flame retardant.

This will provide volumes of polymeric flame retardant exceeding current European Union demand, allowing foam manufacturers to phase out HBCD by the European sunset date of 21 August 2015, according to Dow. While there will be a five-year exemption from the Stockholm Convention ban on HBCD for expanded and extruded polystyrene, manufacturers using this exemption will have to make sure that HBCD is clearly identifiable through the life cycle of products.

Inorganic solutions

The growing importance of phosphorus-based flame retardants as alternatives to HBCD in the electrical and electronics sector is underlined by Clariant opening a second production unit in October 2012 in Cologne, Germany, for its metal phosphinate flame retardant, a diethyl phosphinic acid aluminium salt (Depal). The product, trade named Exolit OP, is used mainly by the electrical and electronics sector in switches, plugs and cable sheaths. A related product, Exolit EP, is designed to protect epoxy resins used in printed circuit boards. Clariant claims that in most cases a relatively small dose of Exolit is needed to meet flame protection requirements.

Following Dow’s lead in polymerising bromine, the US start-up FRX Polymers of Chelmsford in Maryland has developed a polymeric form of phosphorus. The company says that it has minimal impact on the properties of the plastics to which it is added, while providing the highest level of protection, as determined by the limiting oxygen index, a measure of the fire resistance of polymers. The company is due to open its first commercial production plant in Antwerp, Belgium, in October.

Phasing out brominated products is also boosting the market for mineral-based flame retardants, as highlighted by an agreement in May 2013 between the US chemicals company Albemarle and Senze Meilu of Shanxi in China to form a joint venture under which they will build a plant to manufacture Albemarle’s alumina trihydrate product, Martinal. One of the main applications for alumina trihydrate is in polyolefin resins used in wires and cables in the energy sector. Mineral flame retardants like alumina trihydrate act by absorbing heat and releasing water vapour to displace oxygen and flammable gases. They also have the advantage that high dosing is required (up to 60%), in effect ‘diluting’ the polymer and reducing the fire load.

Swedish start-up Paxymer has gone back to the drawing board to come up with what it claims is an environmentally friendly flame retardant for polyolefins, providing superior protection with similar dosing to brominated products. Managing director and founder Amit Paul explains that the technology was developed following an approach to Paxymer’s sister company PP Polymer from the Swedish Civil Contingencies Agency, which was worried about effects of burning polymers on fire fighters.

‘The Agency was concerned about all the traditional problems with polymeric materials: heat generation, smoke generation, smoke toxicity, dripping and the ignition of other materials,’ Paul says. ‘That’s what got us looking into the whole area.’

PP Polymers applied its expertise in polymer chemistry in the search for replacements for existing flame retardants. ‘At the time that was mainly bromine [-based products], but now all persistent flame retardants are seen as problematic,’ Paul explains. While there are halogen-free alternatives on the market, in general higher dosing is required to achieve the same level of protection, causing problems in manufacturing plastic products.

The key in coming up with a retardant that overcomes all environmental concerns was to combine a variety of mechanisms. ‘Everyone else is focusing on one aspect, of either stopping fire in the gas phase, or reducing heat release, or stabilising material through the generation of char,’ Paul says.

He does not want to give precise details, but Paul explained that at the heart of Paxymer’s technology is a novel, patented, method of promoting chemical cross-linking in the material of the polymer chains when subjected to fire. This prevents dripping and reduces heat release and smoke generation. Paul believes this provides a better answer to the problem of small molecule brominated fire retardants than switching to polymeric counterparts. ‘Even if you build bromine into macromolecules that don’t bioaccumulate, it is difficult to prove it is safe. We went back to the beginning and said “let’s take out bromine altogether and see where that leads us”.’

Paxymer has a built a production plant near Stockholm and is currently involved in proof of concept work with plastics manufacturers. ‘I can’t name names, but we have a lot of interest.’ says Paul. To date, Paxymer has been funded by the PP Polymer group, but is looking to break even next year.

As new technologies like Paxymer’s reach the market, novel, environmentally-friendly flame retardants are in development. Examples include nanocoatings for polyurethane foams and for fabrics being researched by Jaime Grunlan, of the Polymer Nanocomposites Lab at Texas A&M University in the US. Grunlan has demonstrated it is possible to protect cotton with alternating nanolayers of chitosan (a polymer derived from crustacean shells) and phytic acid (the form in which phosphorus is stored in plants). This coating swells to form a protective foam layer on contact with fire, reducing peak heat release by 50 per cent compared to non-treated cotton in a flame test.

Regulating retardants

While the bans on brominated products have promoted a search for better flame retardants, there is a lack of comprehensive information on the possible toxicological impact and fire performance of alternatives. Filling this gap provided the motivation for Enfiro, a research project funded by the European Union’s Framework Programme 7, which brought together large chemical companies, SMEs and academics to evaluate various possible substitutes for brominated flame retardants. The main objective was to investigate the suitability of alternatives from the point of view of their production, flame retarding abilities, impact on the manufacturing and properties of polymers to which they were added, and their environmental safety.

‘The aim of Enfiro was to demonstrate there are alternatives to brominated flame retardants on the shelf – that are ready to use. All the products tested are commercially available,’ says Paul Cusack, manager of the Chemicals Technology Division at the consultants ITRI, one of the partners in the Enfiro project.

Enfiro considered three types of flame retardant – mineral-based (aluminium trihydroxide and magnesium hydroxide), phosphorus-based and nanoclays (montmorillonite) – in five different application areas: printed circuit boards, electronic components, injection-moulded products, textile coatings and intumescent fire-proofing paints.

The polymers studied were those where there is currently the highest use of brominated flame retardants, including the engineering plastics polycarbonate–acrylonitrile butadiene styrene and polyphenylene ether–high impact polystyrene, both widely used in equipment casings; glass-fibre reinforced thermoplastics used in electrical switches, sockets and connectors; ethylene–vinyl acetate used in cable insulation; and epoxy resins used in printed circuit boards.

Cusack noted there is a particular pressure to find alternatives for the electrical and electronics sector, which accounts for more than half of Europe’s use of brominated flame retardants. ‘Brominated flame retardants have been the mainstay in the electronics industry, with 90–95% of circuit boards still containing [these chemicals], despite the pressure there has been to eliminate them,’ he says.

Half a dozen alternative retardants show good toxicology

Paul Cusack

Electronics manufacturers have looked to phosphorus-based flame retardants as alternatives, but Cusack says substitution is not straightforward, because higher dosing is required to achieve an equivalent effect to brominated counterparts. In addition to undermining the mechanical properties of a plastic, some phosphorus-based flame retardants cause problems because they absorb water. ‘That’s obviously incompatible with the use of plastics as insulators,’ Cusack says. But a new class of metal phosphinates, such as aluminium phosphinate, that are not hygroscopic and have very low solubility in water, overcome these shortcomings. These can be used for both rigid and flexible printed circuit boards.

Enfiro also assessed aluminium trihydroxide together with nanoclays based on montmorillonite as alternatives to brominated flame retardants in the plastic coating of cables and wires. The intumescent system of ammonium polyphosphonate, pentaerythritol and melamine polyphosphate was assessed for fire-proofing textiles. ‘Along with showing whether the alternatives are technically as good and realistically priced, Enfiro also tried to fill in the data gaps on the toxicity of alternatives,’ Cusack says. In addition, they assessed how polymers treated with these alternative flame retardants performed when extruded in manufacturing and how strong the resulting materials were.

An important aspect of Enfiro was that industry, SMEs and academics were involved, Cusack notes. ‘Expertise relating to polymers and fire safety is within companies and private sector research consultancies, while toxicology is mainly carried out in universities,’ he said. In total 14 halogen-free flame retardants were tested. While all fulfilled fire tests, seven were found to be less toxic and accumulated less in the food chain than brominated flame retardants.

Phosphorus-based products came out as the main alternatives, though Cusack noted that in many cases they are not good enough alone and have to be used with other additives.

The most important output of the project, which ran for three years to September 2012 was that ‘it demonstrated it is feasible to replace brominated flame retardants with alternatives. There won’t be blanket replacement tomorrow, but it can be done. At least half a dozen alternative flame retardants show good toxicology,’ Cusack says. ‘I’m sure over the years to come, the use of bromine and chlorine-based flame retardants will fall away.’

Nuala Moran is a science writer based in Cheshire, UK

No comments yet