Andy Extance discovers how scientists are delivering the extremely accurate DNA chemistry and biochemistry needed to make genes – and even genomes

Frustrated by how much synthetic genes cost, Max Berry has ideas that might make them more affordable – and they have put him in an unusual position. He has the backing of perhaps the highest profile gene synthesis project, the international Genome Project (GP)-write. But that backing does not come with any funding.

Berry is a biochemist working at a medical device startup in San Diego, US, and part of the area’s ‘DIY Bio’ community. To aid his employer’s product development, Berry produces and purifies proteins. The company therefore pays ‘a lot of money to synthesise genes’, he says: relatively small ones that instruct organisms to make the proteins Berry works with. ‘It would be nice to have them cheaper,’ he adds.

Scientists believe that unless they can build something they don’t truly understand it

Nancy Kelly, GP-write

Berry submitted his visions for achieving that to GP-write.1 Its ‘founder-leaders’ are determined to synthesise large genomes, and ultimately human ones. Businesswoman Nancy Kelley and her fellow scientific founder-leaders, Harvard’s George Church, Jef Boeke from New York University and Andrew Hessel from Autodesk in San Francisco, all in the US, want to understand ‘the blueprint of life’. ‘Scientists believe that unless they can build something they don’t truly understand it,’ explains New York-based Kelley. ‘Even after the Human Genome Project was completed in the early 2000s, there’s a lot that we still don’t know.’

Comparison against such genome reading work shows the need for better ways to make DNA and assemble genes. Costs of DNA synthesis using well-established phosphoramidite chemistry (see box below), have remained relatively steady for over a decade.2 Crudely multiplying current prices of around 5–17 cents per DNA base letter by the six billion bases in the human genome gives a minimum price tag of $300 million (£215 million) . By comparison, estimates for the cost of sequencing the first whole human genome in 2003 range from $500 million–1 billion – but by 2016 you could sequence a genome for just $1500.

Many teams are now seeking to demolish the barriers preventing phosphoramidite techniques getting cheaper just as dramatically. Assembling large genes in particular is also extremely difficult for traditional synthetic approaches, so some scientists are hunting altogether new methods. With investors and scientists seeing the unmet need, many ideas are spawning startup businesses. And GP-write has chosen Berry’s proposal, perhaps more revolutionary even than those behind the field’s fledgling companies, as a pilot project. But Berry seemingly faces the biggest challenge of all, because GP-write isn’t directly funding such pilot projects. Berry is therefore currently in the remarkable situation of largely acting as a lone scientist.

Phosphoramidite chemistry cycles on

A nucleotide’s deoxyribose sugar unit has two reactive sites, a 3′ hydroxyl directly on the core deoxyribose sugar ring and a 5′ hydroxyl that dangles slightly further out. A nucleotide typically has a phosphate unit on its 5′ hydroxyl, which the 3′ hydroxyl of a neighbouring base can grab onto. The regularity of this 3′-to-5′ arrangement means that DNA usually has a free 3′ hydroxyl at one end, and a free 5’-hydroxyl at the other. That fact is used to distinguish a gene’s ends.

To synthesise DNA using phosphoramidite chemistry, you typically start from a solid support, and add each nucleotide using a four-step cycle. Since 1980, the standard chemical approach has relied on phosphorus(iii) to provide the reactivity to couple with the 5′-hydroxyl group of the previous nucleotide’s deoxyribose sugar. This strategy uses protecting groups on the 5′ of the new nucleotide molecules to prevent them all attaching to each other in solution, rather than to nucleotides on the solid support. You first add the new nucleotide, and then cap any unreacted 5′-hydroxyl groups to avoid later growing longer chains missing a nucleotide. Thirdly you oxidise the phosphorus(iii) to phosphorus(v), and then finally deprotect the new nucleotide’s 5′ hydroxyl group, ready for the next cycle.

Silicon chips in

Berry wants to move away from today’s main DNA-making method, which starts with oligonucleotides. As well as adenine (A), thymine (T), guanine (G) and cytosine (C) bases, nucleotides contain deoxyribose sugar and phosphate units that form DNA’s backbone. Most synthetic genes therefore start from phosphoramidite chemistry, attaching the first nucleotide to a solid surface, such as a glass bead, and adding subsequent nucleotides. Oligo suppliers often organise their beads in columns placed into each of 96 or more wells in synthesis plates. They grow one oligonucleotide sequence in each column, adding the reagents needed in turn on a microlitre scale, usually using automated synthesisers. When complete, a final reaction cleaves the strands from their beads.

To many chemists, phosphoramidite-based synthesis might seem near perfection: in each step, scientists can typically successfully add a new nucleotide to over 99% of growing strands. But that’s still not good enough for large gene synthesis. Exponential decay means that, after 100 couplings that were 99% successful, just 37% of the final mixture would be the desired 100-base oligonucleotide. As a result, oligo synthesis has usually been limited to just this length, around 100 bases.

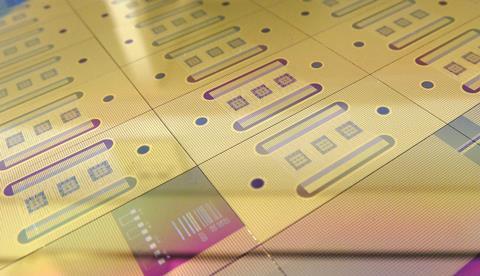

To lower gene synthesis costs, Twist Bioscience in San Francisco, US, uses silicon chips, rather than glass beads, to make much smaller oligonucleotide amounts on. Combining traditional phosphoramidite chemistry and silicon microfabrication, it fits 9600 synthesis sites into the same footprint as a traditional 96-well plate. Furthermore, each site has 121 disc-shaped devices within it that can make an individual sequence, and is individually controlled. Twist chief executive Emily Leproust describes the company’s platform as ‘a silicon chip with devices on it, where DNA can be made in thousands of devices in parallel’.

In the last 12 months, we’ve shipped more than 150,000 genes

Emily Leproust, Twist

‘Our platform significantly lowers the volume of required reagents, specifically the most expensive reagent, by a factor of a million and improves the precision of the synthesis process relative to legacy methods, including 96-well plate and microarray production methods,’ Leproust says. Smaller volumes make reactions more efficient and accurate, with fewer subsequent processing steps needed to get perfect DNA. ‘We are able to consistently produce high-quality oligos with what we believe is an industry-leading error rate of one per thousand base pairs,’ Leproust asserts.

Since Twist took its first orders in April 2015 and made its first commercial shipments a year later, the company’s approach has shown its merits. ‘In the last 12 months, we’ve shipped more than 150,000 genes, a truly remarkable number,’ Leproust says. And that has drawn interest from investors, with the company raising $208 million since it was founded in 2013.

But a startup company in Cambridge, UK, thinks it has a variation on the phosphoramidite/silicon approach able to make nucleotide couplings even more successful. Evonetix will attach nucleotides to silicon chips in around 10,000 different locations, according to chief executive officer Tim Brears. Evonetix hopes to grow oligos more selectively than is currently possible because its chips can heat any single position. ‘We’re able to direct the chemistry at each of those sites, so you’ll be able to grow the oligonucleotides independently,’ Brears tells Chemistry World.

Selective thermal control combines with a currently confidential chemical technology to enable synthesis on a surface without physically separated wells, Brears explains. He therefore believes that Evonetix can simply flow one type of nucleotide across its chips, knowing that it will only add to activated sites. Then, when strands are completed, heating each site on Evonetix’s chips can release them one by one. The company can then employ another novel technology that Brears couldn’t describe in detail to remove any that contain errors. Having been founded in 2015, in January 2018 the company gained £9 million to fund its ongoing development work.

Geneing big

Improving upon ‘gene assembly’ from templates formed of a set of shorter oligonucleotide components is another priority for Berry and other scientists. Gene makers put specific sequences, sometimes called barcodes, at each end of these strands. The barcodes recognise neighbour oligonucleotides using the same base-pairing found in DNA’s double helix and link together. Coding ‘exon’ sections of genes contain around 1000–3000 bases, and barcodes are around 20 bases in length. Consequently, pooling products from a plastic plate filled with 96 columns, each containing copies of one 100-base oligonucleotide, might produce templates for a few short exons. Silicon-based platforms can make hundreds of larger templates.

To get true genes requires transforming lonely single templates into DNA’s double helix. Genome engineers therefore mostly assemble such templates using the polymerase chain reaction (PCR). This enzyme-powered copying process replicates the overlapping oligonucleotide strands into a single continuous gene, and also produces a partner sequence, forming enough double-stranded DNA for genetic engineering.

However, PCR ignores potentially useful features, notes Tom Brown of the University of Oxford in the UK. ‘If we need a gene with chemical modifications inside it, the PCR process cannot be used to amplify the gene as it would eradicate these modifications,’ Brown says. These include natural epigenetic changes that turn genes on or off, or genes with human-introduced modifications like fluorescent groups, which Brown’s company ATDBio specialises in providing.

Therefore, instead of PCR, Brown has collaborated with Ali Tavassoli’s team at the University of Southampton in the UK to assemble modified genes using entirely chemical methods.3 They made 10 strands using conventional phosphoramidite chemistry, putting azide groups on one end of each of them, and alkyne groups on the other. When mixed, the strands recognise each other through base pairing and assemble into two parallel lines. Using ‘click’ chemistry – an azide–alkyne reaction that creates a triazole – then permanently links them into a 335-base pair gene.

‘Click chemistry is useful in making DNA that contains high density site-specific epigenetic, or other chemical, information,’ says Brown. ‘Chemical methods of gene synthesis are not yet suitable for making very large DNA fragments, but miniaturisation, automation and nanotechnology could have roles to play in conjunction with chemical methods of DNA assembly.’

Enzyme time

Yet such ‘stitch them all together and hope it works’ methods are fundamentally limited, explains Jiahao Huang, founder and chief commercial officer of Nuclera Nucleics in Cambridge, UK. If trying to engineer virus genomes, which contain 30,000-40,000 base pairs, for example, the sheer number of approximately 100-base oligo building blocks needed would prevent successful self-assembly. ‘Up to 10 fragments, it will work,’ Huang says. ‘But when you put in 20 fragments, the process just isn’t efficient enough. The more oligos that you want to put together, the less likely it is that they are going to be able to find each other and fit together.’

Nuclera, which has Harvard’s Church on its board, therefore uses terminal deoxynucleotidyl transferase (TdT) enzymes, which can make DNA without templates. In human immune cells, TdT randomly extends DNA encoding areas of antibody proteins that recognise intruders, giving them a better chance of identifying threats. ‘Outside of the body TdT could add about 100 bases per five minutes, which is pretty fast when you consider that each step of phosphoramidite chemistry takes about 10 minutes,’ Huang says. ‘If you leave it longer, it could go up to 1000, even 2000 bases.’ Assembling 10 such fragments would reach virus genome scale.

To tame TdT’s randomness, Nuclera engineered it to assemble protected nucleotides. That means that Huang and his colleagues can add one base, then remove any excess entirely. They can then deprotect the nucleotide, before cleanly adding the next. And they also think that the enzyme’s coupling accuracy could avoid otherwise length-limiting exponential decay. ‘We believe that, using enzymes, accuracy could approach 100% at each step,’ Huang says. So far, Nuclera has raised £875,000 in investments and grants to support that concept.

Berry’s mind has also turned to enzymes. But, seemingly uniquely, he wants to stop gene makers assembling nucleotides ‘one by one, over and over again’. His plans use arrays of around 65,000 DNA fragments that are just eight nucleotides long. ‘Instead of writing letters individually you have a little basket of words that stick together,’ Berry explains. Rather than mixing several large fragments that self-assemble into a gene, Berry wants to add one short word at a time, relying on a combination of enzymes.

We believe that, using enzymes, accuracy could approach 100% at each step

Jiahao Huang, Nuclera Nucleics

The approach would use one word in the array as a template, onto which a polymerase enzyme assembles a partner sequence from nucleotide triphosphate building blocks. A nicking endonuclease enzyme could then cut that newly-assembled sequence free. These steps would happen many times, creating many molecular copies of the desired word. Once they’ve made enough molecules of that word, scientists could then add them to growing double-stranded DNA pieces. They would overlap and base pair with four nucleotides of the previous word on the opposite strand, and enzymes like T4 DNA Ligase or UvsX would secure them in position.

Berry’s word array and enzyme assembly ideas form two of GP-write’s 13 existing pilot projects, and the ones most directly concerned with gene-making methods. GP-write is currently supporting pilot project proposers with recommendation letters to help them pursue their own fundraising efforts. ‘Scientists working on the project have already raised hundreds of millions of dollars for their work,’ says Kelley. She adds that GP-write is only two years into a 10 year project. ‘Eventually when we raise more money we hope to contribute to pilot projects.’

Not working at a university, where he might apply for grant funding, Berry admits he was surprised that his ideas were selected. He is therefore looking for help to explore them. ‘I’d be happy for someone in a lab to just pick this up and I’ll help them out as best I can,’ Berry says. With the need for better gene synthesis clearly meaning innovative ideas attract a great deal of attention and funding, he may not have too long to wait.

Andy Extance is a science writer based in Exeter, UK

References

1 J D Boeke et al, Science, 2016, 353, 126 (DOI: 10.1126/science.aaf6850)

2 R A Hughes and A D Ellington, Cold Spring Harb. Perspect. Biol., 2017, 9, a023812 (DOI: 10.1101/cshperspect.a023812)

3 M Kukwikila et al, Nat Chem, 2017, 9, 1089, (DOI: 10.1038/nchem.2850)

1 Reader's comment