For the first time, scientists have transformed the carbon in biogas into long-chain hydrocarbons using a cold plasma. ‘The beauty of this is strategy is converting waste greenhouse gases, such as biogas or landfill gas, into value-added compounds,’ explains Tianqi Zhang at the University of Sydney and one of the study’s scientists.

Biogas, a mixture of carbon dioxide and methane, is produced when microorganisms decompose organic matter in the absence of oxygen. Although cold plasmas have been used to recycle carbon from biogas in the past, it was restricted to producing simple hydrocarbons such as formic acid, ethanol, isopropanol and acetic acid.

This limitation stems from the nature of plasma, where the energy is high enough to strip electrons from atoms, creating an ionised gas. Cold plasmas aren’t superheated, but they still contain high-energy electrons though their low average temperature means heavy particles – such as ions and neutral atoms – stay relatively cool.

It is the combination of these reactive species, high electron temperatures and brief exposure times that leads to unpredictable chemical reactions and a tendency to produce simpler structures. ‘Typically, a soup of products is formed,’ says James Sullivan, a chemist at University College, Dublin, who was not involved in the study. ‘However, the authors show that selectivity can be tuned to an extent through variation of the CO2/CH4 inlet ratios.’

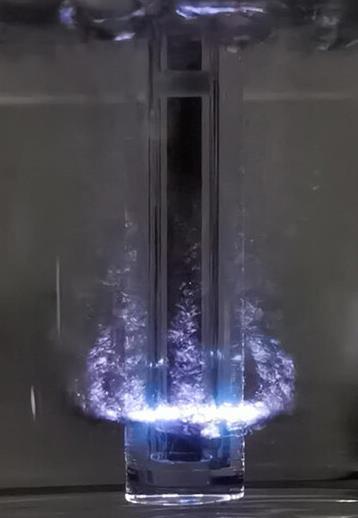

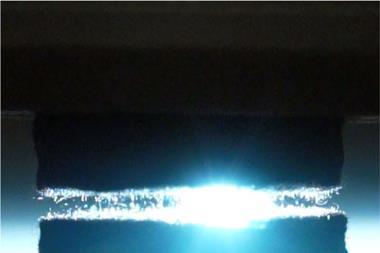

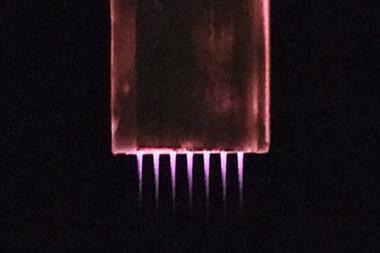

The team used a plasma bubble reactor to create plasma discharges while controlling the mixture of carbon dioxide and methane. In this setup, the plasma interacts directly with water at the point where bubbles form, allowing the gas mixture to become activated on the water’s surface.

‘A key innovation,’ says Lea Winter at Yale University, who was also not involved in the study, ‘is the integration of plasma ionised gases with a water interface, which has a significant impact on the chemistry and allows for the generation of energy-dense solid products.’

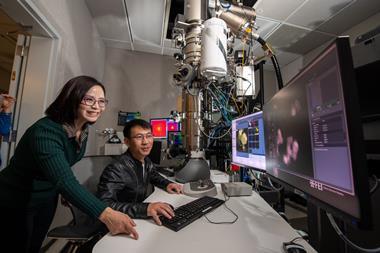

Zhang attributes their breakthrough to a student’s curiosity. ‘At the beginning, [we just had] some mysterious unknown compounds that no one really paid attention to,’ he says. ‘It was our student, Josip, who kept digging into [what these] compounds were.’

Using mass spectrometry and solid-state NMR, they confirmed long-chain hydrocarbons and other oxygenated substances with carbon chains ranging from C8 to C40, which formed when the carbon dioxide content was lower than typically found in biogas.

‘This work illustrates the significant possibilities for making many different types of interesting and valuable compounds, but the mixture of so many different types of chemical products … can be difficult to use in practical applications,’ says Winter. ‘Especially if the targeted market requires relatively pure products, such as for materials manufacturing or pharmaceuticals.’

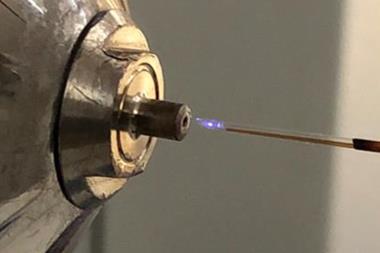

She also points out that while a cold plasma reactor was used, it still has a relatively high energy consumption. ‘However, there may be cases where a plasma process is advantageous compared to other methods,’ she continues. Many processes for upcycling biogas typically rely on high temperatures to drive reactions. But plasma is powered by electricity under atmospheric conditions and could hypothetically be integrated into a renewable energy grid or used in remote locations.

‘I’d be interested to see an energy balance assessment, ie electrical energy to generate the plasma v chemical energy stored in the products,’ added Sullivan.

Winter also points to challenges in scaling this technology. ‘The plasma reactor is intrinsically limited in its dimensions: plasma cannot be generated under atmospheric conditions if the electrode area gets too large, so you essentially have to keep increasing the surface area of the electrode in order to increase the reaction volume,’ she explains. ‘There are remaining challenges for figuring out how this type of reaction could operate and what a reactor would look like at scales relevant for processing substantial biogas streams.’

Zhang says the team is up to the task and is aiming for a kilowatt-scale reactor that could be easily deployed and linked to a solar energy device. ‘Many have questioned the energy efficiency,’ he concedes, ‘but this [can be] conquered with more effort put into new engineering solutions.’

References

J Knezevic et al, J. Am. Chem. Soc., 2024, 146, 12601 (DOI: 10.1021/jacs.4c01641)

No comments yet