Self-assembling silver dendrites boost flux of carbon capture membrane

Non-equilibrium permeation conditions stimulate silver network growth in molten-carbonate membranes

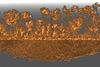

Molten-salt membranes have achieved carbon dioxide capture capability one order of magnitude higher than any other metal-carbonate dual-phase membrane due to their self-assembling silver networks. Growing these networks required conditions previously considered detrimental to stability.