School science project inspires cheaper way to desalinate water

Everyone loves popping bubble wrap after opening a parcel. But scientists in the US have now found a more practical purpose for the packaging material by making a bubble-wrapped sheet that can boil water under sunlight.1

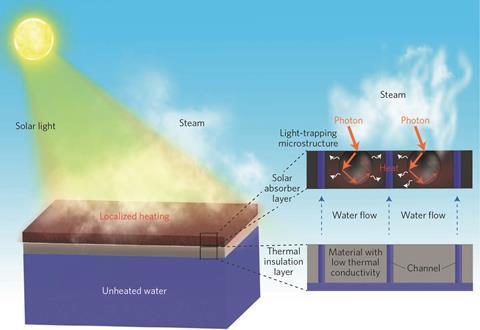

Using sunlight to drive evaporation offers a cheap and simple way to desalinate and purify water supplies. Lenses or mirrors are typically used to concentrate light onto a body of water, with the steam being driven off and condensed to tap into a fresh water supply.

But such a setup is often impractical and costly. ‘Optical concentration is expensive, on the order of $200/m2 (£150/m2),’ says George Ni from the Massachusetts Institute of Technology (MIT). ‘Our research started with a basic question: “Can we generate steam with the sun, without using optical concentration?”’

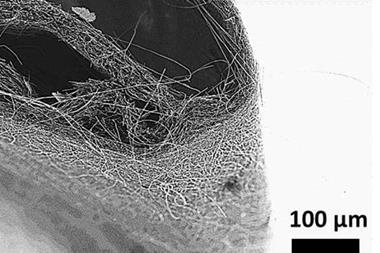

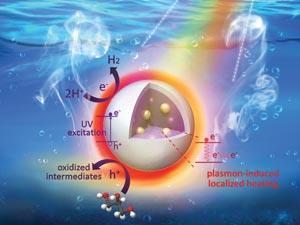

To answer this question, Ni and his colleagues turned their attention to the water’s surface. Back in 2014, the team made a carbon–graphite sponge layered on top of polystyrene foam and floated it on water.2 Under direct sunlight, the film heats up and could boil water drawn up through its pores. But the sheet radiated the heat absorbed too easily and convection losses also stymied its efficiency.

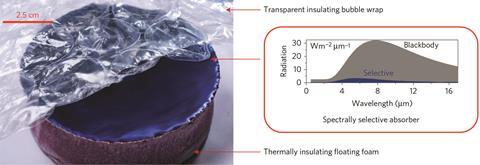

Ni and his colleagues replaced this carbon–graphite layer with a ceramic–coated copper sheet. Known as cermet, the sheet can selectively absorb sunlight and trap infrared radiation. Like their original design, the device boiled surface water and released steam, but air flow still cooled the sheet.

In searching for a cheap solution to overcome these convective losses, the team discovered that bubble wrap may do the trick – with a little help from a colleague’s daughter. ‘[She built] a greenhouse using such materials in her science project, reaching temperatures of up to 71°C in the middle of winter,’ Ni explains.

By placing bubble wrap over the floating absorber and piercing holes through it to allow steam to escape, the convective losses were virtually eliminated. After leaving the cheap solar absorber on MIT’s roof, the team found the film can reach temperatures of up to 100°C, even on cloudy days.

For Peng Tao, a solid state physicist from Shanghai Jiao Tong University in China, the bubble-wrapped device is a nice solution to a challenging problem. ‘The unique system design, detailed thermal analyses and low-cost fabrication materials from this work would not only nicely offer a feasible technological strategy, but also inspire more thinking on how to better advance the solar-thermal technology,’ comments Tao.

References

1 G Ni et al, Nat. Energy, 2016, DOI: 10.1038/nenergy.2016.126

2 H Ghasemi et al, Nat. Commun., 2014, 5, 4449 (DOI: 10.1038/ncomms5549)

No comments yet