Meera Senthilingam

This week, a protective compound that brings strong childhood memories to Brian Clegg

Brian Clegg

When I was young I seemed to spend most of the summer with my extremities – particularly my ears – coated in a pink lotion. These were the days before sun block was common. If you had fair skin and you went out in the sun, there was only one option - you burned. And when you’d burned, on went the calamine. Although the familiar pink colouration of this soothing balm comes from a small proportion of iron oxide, the main active ingredient is an inorganic compound that has had a place in medical chests for at least 2,000 years. It is zinc oxide.

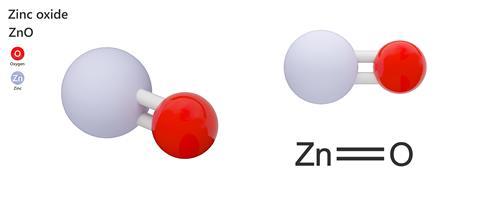

This simple compound, with one oxygen atom for each of zinc, is a plain white powder and one of the most versatile substances around. Apart from the use to treat skin conditions, which goes back to the Ancient Greeks, and may have been used even earlier in India, it has found its way into paints, ceramics, rubber and even food.

In that calamine lotion, the zinc oxide has an antiseptic action, and the lotion was supposed to reduce itching, though there is some doubt how effective it was, beyond the basic cooling effect of the evaporating liquid. It would also have a secondary effect of reducing any further exposure to sunlight that would cause extra burning, as zinc oxide is a good reflector of ultraviolet light. It plays this role in modern sun blocks, which lack the traditional thick, white appearance because the zinc oxide is present in the form of nanoparticles, alongside those of another strong white pigment, titanium dioxide and a range of organic compounds that absorb UV.

Pigments provide the earliest known examples of nanotechnology, although zinc oxide does not provide coloration in a sun block, where its tiny particles are practically transparent to visible light. This is only the beginning of the application of the oxide on the extremely small scale. A whole range of nanostructures can be grown with zinc oxide, including nanowires and films. These are of interest because zinc oxide is an n-type semiconductor, meaning it has a few extra electrons which allow it to conduct. This means it is potentially of use in nanoscale electronics, and it already provides a conductive film for LCDs and solar panels.

The more traditional use of zinc oxide as a pigment has been in the paint box, where it has cropped up since the mid-1800s. Although it isn’t as starkly opaque as titanium dioxide, it provides a good, strong white pigment that forms the basis of the colour Chinese white and is used to give paper a bright white coat. It even finds its way into that most subtle of paint palettes, the cosmetic box, where it forms the bulk basis of the popular mineral makeups. Zinc whites compare well with earlier white pigments like lead oxide as it isn’t poisonous nor blackened by airborne sulfides. It works best mixed with other pigments – as a pure white background it tends not to be used as is quite brittle and can easily crack.

Zinc oxide does occur naturally as zincite, but only in small quantities that can’t be practically extracted. Zinc is a chalcophile, a term applied to minerals that are more likely to form sulfides than oxides, so zinc oxide is generally produced from a sulfide ore. First, zinc metal is extracted before being vaporized to react with the oxygen in the air. This method dates back at least to Roman times, when zinc oxide produced this way was used to react with copper to produce brass.

Surprisingly, the biggest user of zinc oxide is not the cosmetics nor the pigment industry, but the manufacturers of rubber. At least half of the world’s zinc oxide goes into rubber production. Natural rubber is sticky and not particularly durable. It needs to be put through a process, known as vulcanization, that involves adding cross-linkages to the natural polymer chains in the material. This is most frequently done using sulfur, but the process is catalysed using activators, which are typically either zinc oxide or stearic acid. There are also some types of rubber, notably the flexible neoprene, where zinc oxide can be the main vulcanizing agent.

This isn’t the end for this versatile material. Zinc oxide is added to concrete, both to speed up setting and to reduce its susceptibility to water damage. It finds its way into glazes for ceramics too; not as a pigment, but to improve the elasticity of the glaze and reduce cracking. It is used as a way to get dietary zinc into enriched foods, like breakfast cereals, forms part of cigarette filters, helps anti-corrosive paints function and even finds its way into pressurized water nuclear reactors to reduce the risk of corrosion.

Perhaps the most exotic application of zinc oxide takes us back to nanostructures. If textile fibres are coated in zinc oxide structures, they can produce electricity through the piezoelectric property of the semiconductor, generating small electrical currents from the natural flexing of the fibres when worn as a garment. This holds out the prospect of a zinc oxide power source for microelectronics that requires nothing more than natural movement of its wearer to keep it charged.

When compared with some of the more recent uses of zinc oxide, the ritual slathering in calamine lotion I received as a child seems of little importance. There are plenty more modern and better treatments for burns and itching. And yet for those of a certain age, the sight of strong summer sun will always bring to mind zinc oxide’s oldest and most soothing application.

Meera Senthilingam

Science writer Brian Clegg there reminiscing about the healing chemistry of zinc oxide. Next week, what’s that in your drink?

Dan Johnson

Bitter and sweet, cool and refreshing, Alexandra Agutter took a sip of her gin and tonic, letting taste and relaxation wash over her. It was Friday and she had the weekend to look forward to after all. But something was not quite right, an unfamiliar member of the drink’s usual pantheon of flavours. Something… too bitter? Much too bitter. But soon her mind would be incapable of such linear thought; she would grow delirious, her vision blurred and her mouth dry.

Alexandra had been poisoned with the bitter-tasting and infamous compound atropine.

Meera Senthilingam

And discover just how this compound has its toxic effects by joining Dan Johnson in next week’s Chemistry in its Element. Until then, thank you for listening, I’m Meera Senthilingam.

No comments yet